Iyo yepurasitiki jekiseni rekuumba screw barrel inomira pamwoyo pese maitiro ekuumba. Pavanosarudza yepamusoro-soroPlastic Machine Screw Barrelkana aPlastic Twin Screw Extruder Barrel, vagadziri vanoona kuyerera kwezvinhu zviri nyore, kuremara kushoma, uye mitengo yakaderera.Stainless Simbi Mapatya Kurukura Extruder Barrelsarudzo dzinobatsirawo kuwedzera hupenyu hwemidziyo uye kuderedza nguva.

Mabasa Akakosha ePlastiki Injection Molding Screw Barrel

Kunyunguduka uye Homogenizing Plastiki Material

Iyo jekiseni repurasitiki rekuumba screw barrel rinoita chikamu chikuru mukushandura mapurasitiki akasimba mapellets kuita chinhu chakatsetseka, chakanyungudutswa. Mukati medhiramu, sikururu inotenderera uye inosundira ma pellets kumberi. Sezvo pellets inofamba, friction uye mabhandi ekupisa anonyungudusa. Iyo dhiramu inochengeta kupisa kunyangwe, saka plastiki inonyungudika pachiyero chakakodzera. Iyi nzira inobatsira kudzivirira mapundu kana nzvimbo dzinotonhora muzvinyorwa.

Zano: Iyo screw barrel ine matatu makuru nzvimbo — feed, compression, uye metering. Zone imwe neimwe ine basa rakakosha. Nzvimbo yekudyisa inofamba uye inopisa mapellets. Iyo compression zone inonyungudutsa plastiki uye inobvisa mweya. Iyo metering zone inoita kuti kunyungudika kwatsetseka uye kugadzirira jekiseni.

| Zone | Primary Mabasa |

|---|---|

| Feed Zone | Inotakura pellets, preheats, uye compacts kubvisa mhepo homwe. |

| Compression Zone | Inonyungudutsa plastiki uye inobvisa mweya kuburikidza nekumanikidza uye shear. |

| Metering Zone | Homogenizes kunyunguduka, inovaka kudzvanywa, uye inodzikamisa kuyerera kwejekiseni. |

Kudzora tembiricha kunokosha zvikuru. Semuenzaniso, yakaoma UPVC inoda kunyatsodziya kupisa pakati pe180-190°C. Iyo screw barrel inoshandisa ese maheater ekunze uye screw's own movement kugadzira huwandu hwakafanira hwekupisa. Chiyero ichi chinoita kuti plastiki isatsva kana kunamira. Iyo screw's kumhanya inokanganisawo kuti plastiki inonyungudika sei. Kana iyo screw ikatendeuka zvishoma nezvishoma, kunyungudika kunogona kusapisa zvakakwana. Kana ikashanduka nekukurumidza, plastiki inogona kupisa. Iyo yepurasitiki jekiseni rekuumba screw barrel inoita shuwa kuti kunyungudika kwakanyatso kupfura kwese.

Kusanganisa Zvinowedzera uye Kuvimbisa Rudzi Kuenderana

Vagadziri vanowanzo wedzera mavara kana akakosha ekuwedzera kumapurasitiki. Iyo yepurasitiki jekiseni rekuumba screw barrel inosanganisa izvi zvinongedzo munyungudika. Iyo screw's dhizaini, ine yakakosha kusanganisa zvikamu, inobatsira kusanganisa zvese zvakaenzana. Kusanganiswa uku kunomisa mitsetse kana makwapa kubva pakuonekwa muchigadzirwa chekupedzisira.

Kuenderana kwemavara kunogona kuve kwakaoma. Dzimwe nguva,yakaoma pigments inonamira mukati mehopper kana kusasanganisa zvakanaka. Humidity inogona kukanganisa ne resin uye pigment quality. Kunyatso dosing yemacolorants kwakakosha. Machina anoshandisa gravimetric blenders kuyera huwandu hwakakodzera. Mold dhizaini inobatsirawo kuchengetedza mavara kunyangwe munzvimbo dzakasiyana siyana.

Ongorora: Yepamberi screw dhizaini, senge barriers kana Maddock screws, pwanya mapundu uye kuparadzira colorants zvirinani. Aya madhizaini anogonawedzera kusanganisa kugona nepamusoro pe20% uye cheka zvimedu zvimedu kusvika ku30%. Kugara kucheneswa uye kugadzirisa kunoita kuti screw barrel ishande nepamusoro payo, saka mavara anoramba ari echokwadi kubva pabatch kuenda pabatch.

Kutakura uye Kupinza Plastiki Yakanyungudutswa

Kana purasitiki yanyungudutswa nekusanganiswa, screw barrel inofambisa iyo yakanyungudutswa ichienda kune mold. Iyo screw inotenderera mukati mehari inopisa, ichisundidzira kunyungudika kumberi. Kana zvinhu zvakakwana zvikavakwa, screw inoita senge plunger. Inopinza purasitiki yakanyungudutswa muforoma pakumanikidzwa kukuru.

Heino mashandiro anoita maitiro:

- Plastic pellets pinda muchikamu chekudya uye enda kumberi sezvo screw inotendeuka.

- Friction uye kupisa zvinonyungudutsa pellets.

- Iyo screw inomanikidza kunyunguduka, kuve nechokwadi kuti yakatsetseka uye yakaenzana.

- Iyo screw inoenda mberi uye inopinza purasitiki yakanyungudutswa muforoma.

Theplastiki jekiseni molding screw barrelinoita kuti zvinhu zvese zvifambe mushe. Iyo inodzora kudzvanywa uye kuyerera, saka pfuti yega yega inozadza mold zvakakwana. Midziyo yakaoma yedhiramu inosimuka kuti ipfeke uye kubvaruka, kuve nechokwadi chekuti maitiro anoramba akavimbika nekufamba kwenguva.

Kugadzirisa Kuita neiyo Right Plastic Injection Molding Screw Barrel

Mhedzisiro yeScrew Geometry uye Barrel Dhizaini

Screw geometryinoumba kuti plastiki inonyungudika sei uye inosanganiswa mukati medhiramu. Hurefu, chimiro cheshinda, kukwirira, uye kumhanya kwescrew zvese zvine basa. Kana mainjiniya akagadzirisa aya ma paramita, anogona kudzora kuwanda kwekupisa uye kugera iyo plastiki inogamuchira. Izvi zvinobatsira kugadzira yunifomu kunyunguduka uye kuderedza kuremara senge mitsetse kana mabhubhu.

Iyo yekumanikidza reshiyo, iyo inofananidza kudzika kweiyo screw's feed uye metering zones, inokanganisa kuti mapurasitiki akazara sei. Chiyero chepamusoro chinowedzera density uye kusanganisa asi chinogona kusaenderana nekupisa-sensitive mapurasitiki. Back pressure ine basawo. Inosundidzira resin yakanyungudutswa zvakanyanya, ichipwanya zvidimbu zvisina kunyungudika uye kunatsiridza kusanganisa. Nekudaro, yakawandisa kumashure kumanikidza kunogona kukuvadza zvinhu zvakapfava.

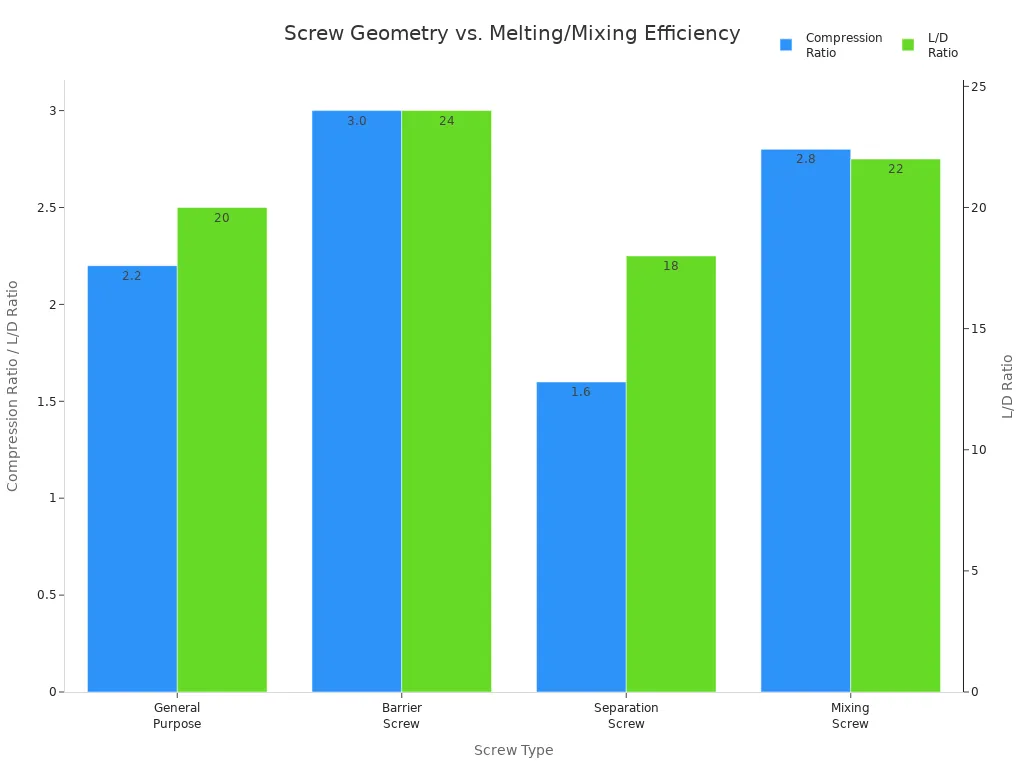

Heino tafura inoratidza kuti akasiyana screw marudzi uye geometry yavo inokanganisa kunyungudika uye kusanganisa kushanda zvakanaka:

| Screw Type | Zvishandiso Zvakakodzera | Compression Ratio | L/D Reshiyo | Kushandiswa kwakajairika | Mhedzisiro paKunyunguduka uye Kusanganisa Kubudirira |

|---|---|---|---|---|---|

| General Chinangwa | ABS, PP, PE | 2.2:1 | 20:1 | Mudziyo Dzimba | Kunyungudika kwakasiyana-siyana uye kusanganiswa neshear ine mwero uye kufanana. |

| Barrier Screw | PA+GF, PC | 3.0:1 | 24:1 | Zvikamu Zvikamu | High shear uye kusanganisa, zviri nani kunyungudutsa homogeneity uye chigadzirwa chemhando. |

| Separation Screw | PVC, POM | 1.6:1 | 18:1 | Mapaipi, Zvikamu | Inodzora shear, inoderedza kuderedzwa, inova nechokwadi chekunyungudika kunoenderana. |

| Kusanganisa Screw | PMMA, PC+GF | 2.8:1 | 22:1 | Light Covers | Kuwedzeredzwa kusanganisa, yunifomu inonyungudika, yakagadziridzwa optical properties. |

Mainjiniya vanowanzo shandisa machati kuenzanisa screw geometry. Chati iri pazasi inoratidza kuti compression ratio uye L/D reshiyo inosiyana sei kune akasiyana masikoruru:

Yakagadzirwa zvakanaka Plastic Injection molding screw barrel ine chaiyo geometry inovimbisa kugadzikana kwepurasitiki, inowirirana tembiricha yekunyungudika, uye kuyerera kwezvinhu zvakatsetseka. Izvi zvinotungamira kune zvirinani kupenya kwepasi, kushomeka kwezvikanganiso, uye yakasimba yakaumbwa zvikamu.

Kusarudzwa kwezvinhu zveDurability uye Wear Resistance

Kusarudza zvinhu zvakanaka zvescrew barrel kunoita mutsauko mukuru pakuti inotora nguva yakareba sei uye nemafambiro ainoita. Vagadziri vanoshandisa simbi dzakaomarara uye machira epamusoro kurwisa kupfeka uye ngura. Semuyenzaniso, 38CrMoAlA nitrided simbi inoshanda nemazvo kumabasa akajairwa, ukuwo SKD61 (H13) simbi yemudziyo inobata masimbi einjiniya akaomarara. Bimetallic mbiya dzine tungsten carbide kana nickel-based alloys inopa yakanyanya kupikisa abrasion nemakemikari.

| Material Type | Pfeka Resistance | Corrosion Resistance | Typical Kuoma | Zvinonyanya kukosha zvekushandisa |

|---|---|---|---|---|

| 38CrMoAlA Nitrided Steel | ★★★☆☆ | ★★☆☆☆ | ~1000 HV (Nitrided) | Kuvimbika kune zvakajairwa zvikumbiro |

| SKD61 (H13) Tool Steel | ★★★★☆ | ★★★☆☆ | 48–52 HRC | Tough engineering resin, thermal stress |

| Bimetallic Barrels | ★★★★★ | ★★★★☆ | 60–68 HRC | Abrasive, fiberglass, flame retardant, recycled mapurasitiki |

Dzimwe sarudzo dzakakurumbira dzinosanganisira AISI 4140 uye 4340 alloy masimbi ekushandisa zvakajairika, D2 uye CPM chishandiso masimbi emapurasitiki abrasive, uye Hastelloy kana Inconel yenzvimbo dzinoparadza. Kurapa kwepamusoro senge nitriding uye chromium plating inowedzera kuoma uye hupenyu hurefu. Kana vagadziri vakasarudza chinhu chakakodzera, vanodzikisa nguva yekudzikira uye mari yekugadzirisa, kuchengetedza kugadzirwa kuchifamba zvakanaka.

Zano: Madhiramu eBimetallic ane yakakwira tungsten carbide zvirimo anogara kwenguva refu, kunyanya kana achigadzira abrasive kana akazadzwa mapolymer.

Kufananidza Screw Barrel kune Akasiyana Plastics

Haasi ese mapurasitiki anoita zvakafanana panguva yekuumbwa. Mhando yega yega inoda chaiyo screw barrel dhizaini kuti uwane mibairo yakanaka. Mainjiniya anotarisa tembiricha yekunyungudika kwepurasitiki, viscosity, uye kugadzikana. Ivo vanofananidza screw geometry, kudzika kwegorofu, uye mbiya coating kune izvo zvinhu zvinodiwa.

Semuyenzaniso, polycarbonate (PC) inoda sikuruu refu ine zvishoma nezvishoma compression reshiyo uye musanganiswa chikamu kudzivirira kuparara. Nylon (PA) inoda mutant screw ine yakakwira compression reshiyo uye kamukana kadiki pakati pesiruu nedhiramu kudzora shear. PVC inoda dhiramu isingadziviriri uye siruu-yekugera yakaderera kudzivirira kupisa uye kuvaka zvinhu.

| Plastic Type | Screw Design Parameters | Impact paHunhu |

|---|---|---|

| Polycarbonate (PC) | Hombe L/D chiyero (~ 26), zvishoma nezvishoma sikururu, compression ratio ~ 2.6, kusanganisa chikamu | Yakanaka plasticizing, inodzivirira kuora, inovandudza homogeneity |

| Nylon (PA) | Mutant sikuruu, L/D 18-20, compression reshiyo 3-3.5, diki gap | Inodzivirira kupisa, inodzora shear, inochengetedza kunyungudika |

| PMMA | Zvishoma nezvishoma sikuruu, L/D 20-22, compression ratio 2.3-2.6, kusanganisa mhete | Kunyungudika kwakarurama, kunodzivirira nyaya dzemwando, kunochengetedza kurongeka |

| PET | L/D ~20, yakaderera shear sikuruu, compression ratio 1.8-2, hapana kusanganisa nzvimbo | Inodzivirira kupisa, inodzora shear, yakakodzera kune zvakadzokororwa zvinhu |

| PVC | Yakaderera shear sikuruu, mbiya isingadziviriri, L/D 16-20, isina cheki mhete | Inodzivirira kupisa uye kuora, kugadzikana kwekushisa kwekushisa |

Kufananidza Plastic Injection molding screw barrel kune rudzi rwepurasitiki kunobatsira kudzivirira hurema hwakaita sekuchinja kwemavara, kunyungudika kusina kukwana, kana kuputika. Inovandudzawo nguva dzekutenderera uye kushanda nesimba.

Ongorora: Kukwidziridza screw barrels kune chaiwo mapurasitiki anogona kuwedzera throughput nekusvika 25% uye kuderedza kuremara, kuchengetedza nguva nemari.

Maintenance Mazano eKurarama Hurefu uye Kuvimbika

Kugaro gadzirisa kunoita kuti screw barrel irambe ichishanda zvakanaka. Vashandi vanofanirwa kuongorora dhiramu kuti harina kupera here, kukwenya, kana kupinza pese panobviswa screw. Kuchenesa nemakomisheni ekuchenesa ekutengesa kunobvisa zvakasara uye kunodzivirira kuwanda kwekabhoni. Kutarisisa kudzvanywa, tembiricha, uye screw kumhanya kunobatsira kuona matambudziko nekukurumidza.

Heano mamwe mazano anoshanda ekugadzirisa:

- Ongorora screw barrel nemaziso uye nemageji pese panobviswa screw.

- Chenesa dhiramu vhiki nevhiki kuti urambe uchimhanya, kana mazuva ese 2-3 kana uchichinja mapurasitiki kazhinji.

- Zora zvikamu zvinofamba zuva nezuva uye zvizore vhiki nevhiki negirisi yemhando yepamusoro.

- Shandisa mbishi yakachena uye uzvichengete nemazvo kudzivirira kusvibiswa.

- Dzidzisa vashandi kuti vaone zviratidzo zvekupfekwa uye kuchengeta matanda ekugadzirisa ane hudzamu.

- Stock spare parts kuderedza nguva.

- Mushure mekuvhara, mhanyisa sikururu nekumhanya kwakaderera kuti ugovane mapurasitiki asara, geza nemishonga yakakosha, uye isa mafuta ekudzivirira.

Callout: Bimetallic barrels ane iron-based liners inogona kugara yakapetwa katatu kupfuura yakajairwa screws.Kurongeka kwakakodzera uye lubricationkuwedzera hupenyu uye kuderedza kuwanda kwekugadzirisa.

Yakanyatsochengetedzwa Plastic Injection molding screw barrel inopa inowirirana mhando, inoderedza nguva yekudzikira, uye inotsigira kugadzirwa kwakanaka.

Iyo Plastic Injection molding screw barrel inoita basa rakakosha mukuunza inowirirana mhando yechigadzirwa uye kugadzirwa kwakanaka.

- Yepamusoro-mhando screw barrels inovandudza kunyunguduka kuenderana, kuderedza zvimedu, uye kuwedzera kushanda zvakanaka.

- Kugadziriswa nguva dzose kunodzivirira kuderera uye kunowedzera hupenyu hwemidziyo.

- Kuchengetedza kwezvinhu uye simba kunowedzera nekukurumidza.

- Kukurumidza kuchinja kunowedzera huwandu uye purofiti.

FAQ

Ndezvipi zviratidzo zvinoratidza screw barrel inoda kutsiviwa?

Vashandi vanocherechedza kusaenzana kunyunguduka, kuwedzera kukanganisa, kana kunonoka kutenderera. Vanoonawo kupfeka kunoonekwa, mavanga, kana kupinza mukati medhiramu.

Kangani munhu anofanirwa kuchenesa dhiramu rekupura?

Vazhinji vagadziri vanochenesa chirongo vhiki nevhiki. Kana vakachinja mapurasitiki kazhinji, vanoachenesa mazuva maviri kana matatu oga oga.

Ko imwe screw barrel ingashanda kune ese mapurasitiki?

Kwete, mhando yega yega yepurasitiki inoda chaiyo screw barrel dhizaini. Kushandisa mutambo wakakodzera kunovandudza kunaka kwechigadzirwa uye kunoderedza marara.

Nguva yekutumira: Aug-15-2025