Pandinoshanda nePlastiki Injection molding screw barrel, ini ndinoona magadzirirwo ayo maumbirwo ayo chikamu chese chatinogadzira. Simulation zvidzidzo zvinoratidza kuti kunyangeshanduko diki mukumhanyisa screwkana compression zones inogona kuwedzera kunaka uye kushanda zvakanaka. Kana ndikashandisa aTwin Plastic Screw Barrelkana kumhanya aPlastic Extrusion Production Line, kodzeroPlastic Machine Screw Barrelinoita mutsauko wese.

Mabasa ePlastiki Injection molding screw barrel

Pandinotarisa pamwoyo wechero muchina wekugadzira jekiseni, ndinoona dhiramu rekukwenya richiita kusimudza zvinorema. Haisi chubhu chete ine siruuru mukati. Dhizaini uye kushanda kweiyo screw barrel inogadzirisa nhanho imwe neimwe yekuumbwa. Rega ndiputse mabasa ayo makuru uye nei rimwe nerimwe richikosha zvakanyanya.

Kunyunguduka uye kusanganiswa kwePolymers

Chinhu chekutanga chinoitika mukati me screw barrel kunyunguduka uye kusanganiswa kwepurasitiki pellets. Ini ndinodurura pellets muhopi, uye screw inotanga kutenderera mukati mebhodhoro rinopisa. Iyo dhiramu ine dzakasiyana tembiricha nzvimbo, saka epurasitiki inopisa zvishoma nezvishoma. Kunyanya kunyungudika kunobva mukupokana uye kudzvanywa kwakagadzirwa nescrew kukwesha pamapellets nemadziro embiru. Izvi zvinoita kuti purasitiki risadzise uye inobatsira kuti inyunguduke zvakaenzana.

- Iyo screw barrel ine inotenderera helical screw mukati medhiramu yakamira.

- Zvidziidzo zvembiya zvinodziya mbiya ndisati ndatanga, saka iyo polima inonamira uye inotanga kunyungudika.

- Kana screw yatenderera, simba rakawanda rekunyungudutsa rinobva kushear pakati pescrew nemadziro edhiramu.

- Iyo screw's dhizaini, kunyanya nzira iyo kudzika kwechiteshi kunoita diki muchikamu chekumanikidza, inomanikidza purasitiki isina kunyungudutswa kumadziro anopisa. Izvi zvinowedzera kunyunguduka uye kusanganisa.

- Sezvo plastiki inofamba ichienda mberi, dziva rekunyunguduka rinokura kusvikira zvinhu zvose zvanyunguduka. Kuramba kugerwa kunosanganisa purasitiki yakanyungudutswa zvakanyanya.

Ndinogara ndichiteerera kuti mapurasitiki anonyungudika sei uye anosanganiswa. Kana iyo yakanyunguduka isiri yunifomu, ndinoona matambudziko senge mitsetse kana isina simba muzvikamu zvekupedzisira. Iyo screw barrel dhizaini, kusanganisira yayokureba, kukwirira, nekudzika kwegwara, inoita mutsauko mukuru mukunyungudusa kwainoita uye kusanganisa marudzi akasiyana emapurasitiki.

Zano:Mazhinji emagetsi edhiraivha mune screw barrel - angangoita 85-90% - anoenda mukunyungudutsa epurasitiki, kwete kungoiendesa mberi.

Kutumira uye Homogenization

Kana plastiki yangotanga kunyunguduka, screw barrel inotora rimwe basa rakakosha: kuendesa zvinhu kumberi uye kuve nechokwadi kuti yakanyatsofanana. Ini ndinofunga izvi se "mhando yekudzora" zone mukati memuchina. Iyo screw barrel yakakamurwa kuita zvikamu zvitatu zvikuru, chimwe nechimwe chine basa rayo:

| Screw Zone | Hunhu Hunokosha | Primary Mabasa |

|---|---|---|

| Feed Zone | Yakadzika chiteshi, kudzika nguva dzose, 50-60% kureba | Inotakura ma pellets akasimba mudhiramu; inotanga preheating kuburikidza ne friction uye conduction; compacts zvinhu zvinobvisa mhepo homwe |

| Compression Zone | Zvishoma nezvishoma zvichidzika kudzika kwechiteshi, 20-30% kureba | Inonyungudutsa mapepa epurasitiki; compresses zvinhu kuwedzera kumanikidza; inobvisa mweya kubva mukunyunguduka |

| Metering Zone | Shallowest channel, kudzika nguva dzose, 20-30% kureba | Homogenizes kunyunguduka tembiricha uye kuumbwa; inogadzira kumanikidzwa kweextrusion; inodzora kuyerera kwehuwandu |

Ndakaona kuti screw barrel's geometry - senge mbiru uye kudzika kwescrew ndege - inokanganisa zvakananga mafambiro nekusanganiswa kwepurasitiki.Grooved barrels, somuenzaniso, zvinobatsira kuti dzvinyiriro irambe yakatsiga uye kuvandudza kuwanda kwezvinhu zvandinogona kugadzira, kunyange pakumhanya kukuru. Kana ini ndichida kuwedzera kuburitsa, ini ndinogona kuwedzera screw pitch kana kushandisa hombe yekuvhura yekudyisa. Ese aya dhizaini tweaks anobatsira screw barrel kuunza yakatsiga, yunifomu kunyunguduka kune mold, zvinoreva kushoma hurema uye zvimwe zvinowirirana zvikamu.

- Barel tembiricha controlinokosha pakunyunguduka kweyunifomu uye kushanda zvakanaka.

- Nzvimbo dzakawanda dzekudziya dzinowedzera zvishoma nezvishoma tembiricha kusvika kufa dzinoderedza kuremara uye kugadzirisa nguva dzekutenderera.

- Iyo screw's configuration inogonesa kusanganisa uye kuburitsa kushanda zvakanaka.

Jekiseni uye Mold Kuzadza

Mushure mekunge plastiki yanyungudutswa nekusanganiswa, screw barrel inogadzirira nguva huru: kubaya purasitiki yakanyungudutswa muforoma. Heano maitiro andinoona maitiro achiitika:

- Iyo screw barrel inogamuchira mbishi epurasitiki pellets kubva kune hopper.

- Iyo screw inotenderera uye inoenda kumberi mukati mehari inopisa, kunyunguduka, kusanganisa, uye homogenizing purasitiki.

- Mechanical shearing ne screw inoburitsa kupisa kwefriction, kuderedza viscosity yepurasitiki kuti ikwanise kuyerera.

- Zvinhu zvakanyungudutswa zvinoungana kumberi kwescuru, zvichigadzira "pfuti" inongori huwandu hwakakodzera kuzadza mold.

- Siruuru inopinza pfuti yakanyungudutswa pakumanikidzwa kukuru uye nekukasira mugomba reforoma.

- Iyo screw inochengetedza kurongedza kuti ive nechokwadi chekuti mold inozadza zvizere uye inotsiva chero shrinkage.

- Mushure mekunge mold yazadza, screw inodzosera kugadzirira kutenderera kunotevera apo chikamu chinotonhora.

Ndinogara ndichiona kuita kwe screw barrel panguva ino. Kana tembiricha yekunyunguduka kana kuyerera isingaenderane, ndinowana kuzadza mold isina kuenzana kana nguva refu yekutenderera. Kushanda kwescrew barrel mukunyunguduka uye kufamba kwepurasitiki nekukurumidza kunondibatsira kuchengeta nguva dzekutenderera dziri pfupi uye chikamu chemhando yepamusoro. Ndosaka ini ndichitarisa zvakanyanya kune dhizaini uye mamiriro ePlastiki Injection molding screw barrel-inonyatso kudzora maitiro ese kubva pakutanga kusvika pakupedzisira.

Screw Dhizaini uye Impact Yayo pane Molding Mhedzisiro

Kufananidza Screw Geometry kune Resin Types

Pandinosarudza screw yemuchina wangu, ndinogara ndichifunga nezvemhando yeresin yandinoronga kushandisa. Haisi screw yese inoshanda nemapurasitiki ese. Zvitoro zvakawanda zvinoshandisa masikiru e-general-chinangwa, asi ini ndaona kuti izvi zvinogona kukonzera sei matambudziko senge kusaenzana kunyungudika uye matema matema muchigadzirwa chekupedzisira. Imhaka yekuti mamwe marezeni anoda akakosha screw dhizaini kudzivirira nzvimbo dzakafa uye chengetedza yunifomu yakanyungudika.

- Barriers screws inopatsanura yakasimba pellets kubva kupurasitiki yakanyungudutswa, iyo inobatsira kunyungudutsa zvinhu nekukurumidza uye kuderedza kushandiswa kwesimba.

- Kusanganisa zvikamu, seMaddock kana zig-zag musanganiswa, ita shuwa kuti tembiricha yekunyunguduka uye ruvara zvinogara zvakangofanana, saka ini ndinoona mashoma ekuyerera mamaki uye weld mitsetse.

- Mamwe madhizaini ekukurisa, senge CRD yekusanganisa screw, shandisa elongational kuyerera pane kugera. Izvi zvinoita kuti polymer isaputsike uye inondibatsira kudzivirira gels uye kuchinja kwemavara.

Zvidzidzo zvemaindasitiri zvinoratidza kuti anosvika makumi masere muzana emuchina ane resin degradation nyaya dzakabatana ne screw design. Ini ndinogara ndichifananidza screw geometry kune resin mhando kuchengetedza nhengo dzangu dzakasimba uye dzisina hurema.

Mhedzisiro paKunyunguduka, Kusanganisa, uye Kubuda Kwemhando

Iyo screw's geometry inoumba kuti plastiki inonyungudika sei, inosanganiswa, uye inoyerera. Ndakaona kuti madhizaini epamberi, senge ndege dzinodzivirira uye zvikamu zvekusanganisa, anosundidzira isina kunyungudutswa polymer padhuze nemadziro ebhari. Izvi zvinowedzera kupisa kweshear uye zvinobatsira kunyunguduka kuve yunifomu.

Heano kutarisa nekukurumidza maitiro akasiyana screw geometries:

| Kurukura Geometry Type | Melting Efficiency | Kusanganisa Kubudirira | Output Quality |

|---|---|---|---|

| Barrier Screw | High | Pakati nepakati | Zvakanaka, kana throughput iri optimal |

| Zvitatu-Chikamu Chikurunga | Pakati nepakati | High | Yakanaka kwazvo nekusanganiswa kwakakodzera |

| Maddock Mixer | Pakati nepakati | High | Yakanakisa kune ruvara uye tembiricha kufanana |

Ndinogara ndichivavarira kuenzanisa. Kana ndikasundira kune yakakwira throughput, ndinoisa panjodzi yekurasikirwa nehomogeneity. Thekurudyi sikuruu dhizainimune yangu Plastic Injection molding screw barrel inondibatsira kuchengeta tembiricha yakanyunguduka yakatsiga, kuderedza hurema, uye kuendesa zvikamu zvinowirirana kutenderera kwese.

Zano: Ndinotarisa kunyungudika kwemhando nekutarisa kuenderana kwemavara uye chikamu chesimba. Iyo screw yakagadzirwa zvakanaka inoita kuti izvi zvive nyore.

Material Selection for Plastic Injection molding screw barrel

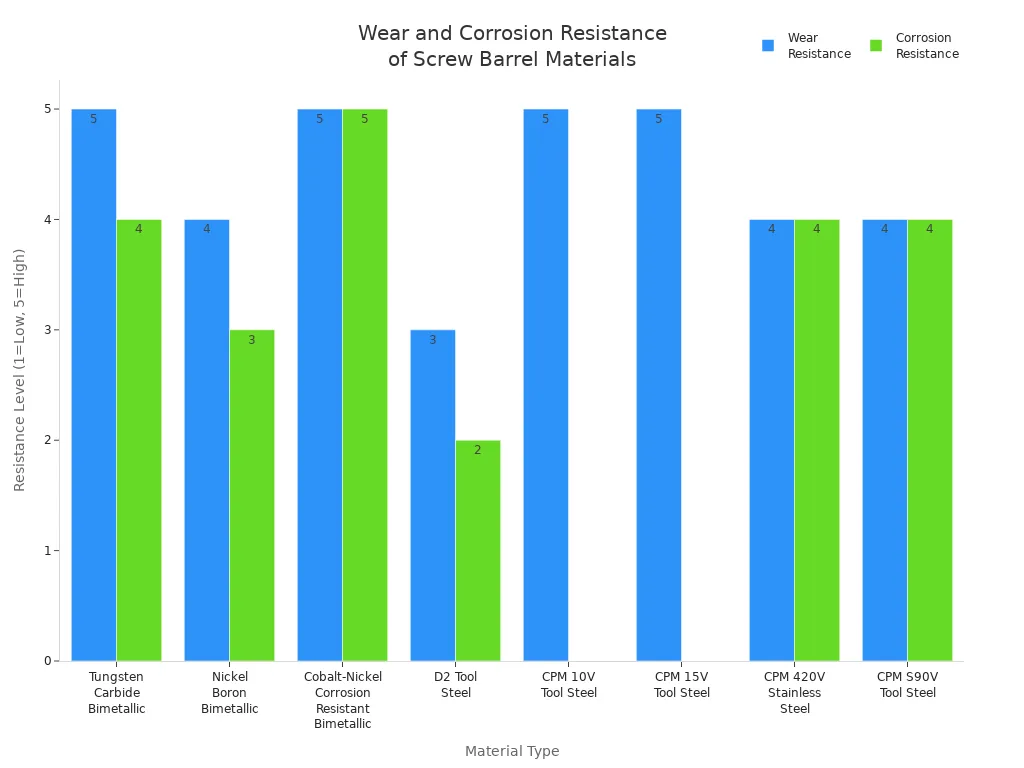

Wear and Corrosion Resistance

Pandinotora zvinhu zve aPlastic Injection molding screw barrel, Ndinogara ndichifunga nezvekuoma kwakaita basa racho. Mamwe mapurasitiki ane magirazi fiber kana zvicherwa anoita sesandpaper, achipfeka pasi screw uye mbiya nekukurumidza. Zvimwe, zvakadai sePVC kana mashizha anodzora moto, anogona kukanganisa zvikuru. Ini ndinoda kuti midziyo yangu igare, saka ndinotsvaga zvinhu zvinomira pakupfeka nekuora.

Heino kutarisa nekukurumidza kune dzimwe sarudzo dzakajairika:

| Material Type | Pfeka Resistance | Corrosion Resistance | Best Use Case |

|---|---|---|---|

| Nitrided Steel | Kugona | Murombo | Zvisina kuzadzwa, zvisingatauriki |

| Bimetallic Barrels | Excellent | Zvakanaka / Zvakanaka | Zvinhu zvakazadzwa, zvinokuvadza, kana zvinoparadza |

| Tool Steel (D2, CPM series) | High | Pakati/pamusoro | Girazi/mineral yakazadzwa kana yakaoma additives |

| Specialty Coated Barrels | High High | High | Kunyanya kupfeka / kuora, hutsinye resins |

Ndakaona kuti kushandisa bimetallic barrels kana simbi yemidziyo inogona kuwedzera hupenyu hwemidziyo yangu. Zvinhu izvi zvinoramba kukwenya uye kurwisa kwemakemikari. Pandinoshandisa musanganiswa wakakodzera, ndinopedza nguva shoma pakugadzirisa uye nguva yakawanda ndichiita zvikamu zvakanaka.

Zano: Kana ndikagadzira mapurasitiki akawanda akazadzwa negirazi kana murazvo, ndinogara ndichisarudza madhiramu ane machira epamusoro kana bimetallic liners. Izvi zvinoita kuti hurongwa hwangu hwekugadzirisa hurambe huchizivikanwa uye nguva yangu yekudzikira yakaderera.

Kusarudza Zvishandiso zveChaiyo Polymers uye Zvinowedzera

Plastiki yega yega ine hunhu hwayo. Vamwe vakapfava, nepo vamwe vane hutsinye pamidziyo. Pandinosarudza zvinhu zvesikuru yangu nedhiramu, ndinozvifananidza nemapurasitiki uye zvekuwedzera zvandinoshandisa zvakanyanya.

- Girazi faibha nemaminerari zvinotsenga simbi dzakapfava, saka ndinoenda kune akaomeswa alloys kana tungsten carbide coatings.

- Mapurasitiki anoparadza, akaita sePVC kana fluoropolymers, anoda mbiya dzakagadzirwa kubva ku nickel-based alloys kana simbi isina tsvina.

- Kupisa-kupisa resins kunogona kukonzera kuneta kwekupisa, saka ini ndinotarisa kuti iyoscrew uye mbiyakuwedzera pamwero mumwe chete.

- Kana ndikashandisa akawanda akasiyana zvinhu, ini dzimwe nguva ndinotora modular screw dhizaini. Nenzira iyo, ndinogona kuchinjanisa zvikamu zvakasakara pasina kutsiva screw yese.

Ndinogara ndichitaura nemutengesi wangu we resin kuti ndiwane mazano. Vanoziva kuti ndezvipi zvinhu zvinoshanda zvakanyanya nemapurasitiki avo. Nekusarudza zvinhu zvakanaka, ini ndinochengeta yangu Plastic Injection molding screw barrel ichimhanya zvakanaka uye kudzivirira kuparara kunoshamisa.

Zvitsva muPlastiki Injection yekuumba screw barrel Technology

Yepamberi Coatings uye Surface Kurapwa

Ndakaona mabatiro epamusoro uye marapirwo epamusoro anogona kuita mutsauko wakakura mukureba mbichana dzangu dze screw. Pandinoshandisa madhiramu ane bimetallic linings kana tungsten carbide coatings, ndinoona kushoma kupera uye kushomeka kushoma. Aya mabhanhire anobatsira mbiya kuramba abrasion uye corrosion, kunyangwe pandinomhanyisa zvinhu zvakaomarara senge magirazi akazara resins. Zvimwe zvipfeko zvinoshandisa nano-materials, izvo zvinobatsira nekupisa kupisa uye kuchengetedza nzira yakasimba. Iniwo ndinofarira kuti marapiro aya anoderedza simbi-kune-simbi kubata, saka screw nedhiramu hazvikuyanirana pasi nekukurumidza.

Hezvino izvo zvandinotsvaga mune advanced coatings:

- Pfeka-resistant alloys anoenderana nezvinhu zvandinogadzira

- Kurapa kwepamusoro kunobata kupisa kwakanyanya uye makemikari ane hukasha

- Coatings inochengetedza nzira yakagadzikana uye inoderedza nguva

Pandinosarudza jasi rakakodzera, ndinopedza nguva shoma pakugadzirisa uye nguva yakawanda ndichigadzira zvidimbu zvakanaka. Unyanzvi hweMetallurgical hunonyanya kukosha pano. Iko kusanganisa kwakaringana kwealloy uye kupfeka kunogona kaviri kana kunyange katatu hupenyu hwesevhisi yemidziyo yangu.

Tsika Madhizaini eSpecialized Applications

Dzimwe nguva, ini ndinoda zvinopfuura kungoita akajairwa screw barrel. Tsika madhizaini anondibatsira kugadzirisa akasarudzika ekuumba matambudziko. Semuenzaniso, ndakashandisa conical twin screw barrels kuvandudza kusanganisa uye kudziya kwekutonga. Ndakaonawo masiruuru akagadzirirwa kukurumidza kutenderera nguva, kunatsiridza kunyungudika, uye kuderedza kugera zvakanyanya.

Dzimwe sarudzo dzandinofunga kune dzetsika dhizaini:

- Madhiri nemadhiramu akagadzirwa kubva kune akakosha simbi seD2 Tool Steel kana CPM mamakisi

- Kuomeswa kwepamusoro seStellite kana Colmonoy kuti iwedzere kusimba

- Midziyo yakarongedzerwa zvinhu chaizvo, senge nickel base ine carbide yemapolima akazadzwa negirazi.

- Tsika mavharuvhu magungano uye ekupedzisira zvivharo zvine machira epamusoro

Tsika mhinduro rega ndifanane nemidziyo yangu kune izvo chaizvo zvinodiwa zvemaitiro angu. Izvi zvinoreva zvirinani chikamu chemhando, kukurumidza kutenderera, uye kushomeka nguva. Ini ndinogara ndichishanda nechikwata chedhizaini chinonzwisisa application yangu uye inokwanisa kuendesa hunyanzvi hwemhando yepamusoro.

Kuziva uye Kugadzirisa Matambudziko Screw Barrel

Zviratidzo Zvakajairika Zvekupfeka kana Kukundikana

Pandinomhanyisa michina yangu, ndinogara ndakatarisa kune yekutanga yambiro zviratidzo kuti chimwe chinhu chakashata ne screw barrel. Kuona nyaya idzi pachine nguva kunondibatsira kudzivirira matambudziko makuru gare gare. Hezvino zvimwe zvinhu zvandinotarisa:

- Material inodeuka ichitenderedza dhiramu, izvo zvinowanzoreva zvisimbiso zvakasakara kana kusunungurwa kwakanyanyisa.

- Zvikamu zvinobuda nehukuru husingaenderane kana mavara matema-awa anowanzo nongedzera kukusasanganiswa kwakanaka kana kusvibiswa.

- Kupisa kwakanyanya kwekushanda, dzimwe nguva kunokonzerwa nekukweshana kana kabhoni kuvaka mukati medhiramu.

- Ruzha runoshamisa kana mavhinga panguva yekushanda. Izvi zvinogona kureva kusarongeka, mabhengi akatyoka, kana chinhu chisiri mukati.

- Pressure spikes kana kunyungudika kwakashata kuyerera, izvo zvinoita kuti zviome kuzadza mold nemazvo.

- Mabhuroka kana zvinhu zvinovaka mukati medhiramu, zvinotungamira kune yekudzikira uye yakaipa zvikamu.

- Matambudziko ekusanganisa mavara kana kusvibiswa, kazhinji kubva kune zvakasara kana tembiricha yakashata.

- Kuona ngura kana gomba, kunyanya kana ndikamhanyisa marara anoparadza.

- Akasakara screw ndege kana barrel lining, iyo yandinoona kazhinji kana ndichishandisa abrasive fillers segirazi fiber.

- Kunyungudika kunononoka, zvimwe zvimedu, uye nguva refu yekutendererasezvo midziyo inopera.

Kana ndikacherechedza chimwe chezviratidzo izvi, ndoziva kuti yave nguva yekutarisa screw barrel zvinhu zvisati zvanyanya kuipa.

Kushanda Kugadzirisa uye Kugadzirisa Mazano

Kuti michina yangu irambe ichishanda zvakanaka, ndinotevera muitiro wenguva dzose wokugadzirisa. Hezvino izvo zvinondinakira:

- Ndinoshandisa mafuta ekuzora anokurudzirwa nemugadziri.

- Ini ndinotarisa hydraulic oiri mazinga zuva rega rega uye kutsiva mafuta pahurongwa.

- Ndinotarisa tembiricha yemafuta uye handimboregi ichipisa zvakanyanya.

- Ndinoongorora hose, pombi, uye mavharuvhu kuti haabvisi here kana kusakara.

- Ndinochenesa uye kuomesa mabhandi ekudziya mwedzi wega wega.

- Ini ndinoshandisa thermal imaging kuona matambudziko ekupisa nekukurumidza.

- Ini ndinotarisisa nguva dzekutenderera, mareti ezvikara, uye kushandiswa kwesimba kubata nyaya dzisati dzakura.

- Ndinogara ndichichenesa screw uye mbiya kudzivirira kuvaka.

- Ini ndinove nechokwadi chekuti screw inogara yakatwasuka uye yakarongeka panguva yekuisa.

- Ini ndinodzidzisa timu yangu kuona zviratidzo zvekutanga zvekusakara uye kuchengetedza mamiriro ekugadzirisa akadzikama.

Kugara pamusoro pemabasa aya kunondibatsira kuti ndidzivise kuparara uye kuchengetedza mutsara wangu wekugadzira unoshanda.

Pandinotarisa pasainzi kuseri kwePlastiki Injection molding screw barrel, ndinoona mibairo chaiyo. Ini ndinowana zvikamu zvirinani, kukurumidza kutenderera, uye kushomeka nguva.

- Mari yekuchengetedza yakaderera

- Kuvandudzwa kwechigadzirwa

- Hurefu hwehupenyu hwemidziyo

Kuramba wakapinza nescrew barrel sainzi inochengeta kugadzira kwangu kwakavimbika uye kwakanaka.

FAQ

Ndezvipi zviratidzo zvinondiudza screw barrel yangu inoda kutsiviwa?

Ndinoona mamwe matema matema, zvikamu zvisina kuenzana, kana ruzha runoshamisa. Kana ndikaona izvi, ndinotarisa screw barrel kuti yakasakara kana kukuvara ipapo.

Kangani kandinofanira kuchenesa screw barrel yangu?

Ini ndinochenesa screw barrel yangu mushure mekuchinja kwese kwezvinhu. Pakumhanya nguva dzose, ndinoitarisa nekuichenesa kamwechete pasvondo kudzivirira kuvaka.

Ini ndinogona kushandisa screw barrel kune ese marudzi emapurasitiki?

- Ini ndinodzivirira kushandisa screw barrel kune ese epurasitiki.

- Mamwe mapurasitiki anoda zvinhu zvakakosha kana mabhanhire kudzivirira kusakara kana kuora.

Nguva yekutumira: Aug-20-2025