PE madiki ezvakatipoteredza granulator anobatsira vagadziri kucheka kushandiswa kwesimba neakangwara maficha uye tekinoroji nyowani. Mamodheru achangoburwa anoratidza mhedzisiro inonakidza:

| Metric | 2025 Kuderedza vs. Makore Akapfuura |

|---|---|

| Kushandisa Simba (kW-h/tonne) | 40% yakaderera |

| Greenhouse Gas Emissions | 33% zvishoma |

| Fossil Kushandiswa Kwemafuta | 45% zvishoma |

Vanoshandisamota dzepamusoro-soro, kutambisa kupisa kudzoreredza, uye masisitimu anotonhodzwa nemhepo. AnEnvironment Mini-Pelletizer MachineuyeMvura isina mvura Granulator Machineanogona kubataPvc Pelletizing Extrusionzvinobudirira.

Simba-Kuchengetedza Zvimiro zvePE Diki Ezvakatipoteredza Granulator

Yakanyanya-Kubudirira Motor Systems

PE madiki ezvakatipoteredza granulator muna 2025 anoshandisa advanced mota tekinoroji kuchengetedza simba uye kuwedzera mashandiro. Michina iyi inovimba nemagetsi ekutyaira ane simba remota kubva pa22 kW kusvika pa110 kW, zvichienderana nekukura kwemuenzaniso. Iwo mota dzinoshanda nehunyanzvi kubva pa200 kusvika 1200 kg/h, dzichiita kuti dzive dzakakwana kune madiki uye epakati mashandiro ekudzokorodza. Tafura iri pazasi inoratidza mamwe akakosha tekinoroji ruzivo:

| Tsanangudzo | Details |

|---|---|

| Motokari Power Range | 22 kW kusvika 110 kW |

| Drive Type | Zvigadzirwa zvemagetsi |

| Auxiliary Drive Power | 1.1 kW |

| Capacity Range | 200-1200 kg / awa |

| Application | PE uye mamwe epurasitiki granulation |

Aya mamota-anoshanda zvakanyanya anoshandisa servo madhiraivha uye nehungwaru kutonga. Vanobatsira vashandisi kuchengetedza simba rinosvika makumi mana muzana kana zvichienzaniswa nemamotors ekare. Chaiyo-nguva yekutarisa uye otomatiki inochengetedza sisitimu ichimhanya zvakanaka, kuderedza nguva yekudzikira uye kucheka mutengo wemagetsi.

Yakagadziridzwa Blade uye Dhizaini Yekufambisa

Iyo blade uye yekufambisa sisitimu muPE diki nharaunda granulator inoita basa rakakura mukuchengetedza simba. Vagadziri vanoshandisa mashizha emhando akagadzirwa kubva kumhando yepamusoro senge tungsten carbide kana simbi inomhanya. Zvinhu izvi zvinogara kwenguva refu uye kucheka zvakanyanya. Hedzino dzimwe nzira optimized blades rubatsiro:

- Precision blade angles inoderedza mutoro wemota uye kushandisa simba.

- Machira epamberi, akadai setitanium nitride, inodzika friction nekusvika 40%.

- Kugara kuchenesa ultrasonic kunochengeta mashizha akapinza uye kudzivirira zvakasara kuvaka.

- Flat blades inoshanda zvakanyanya kune mapurasitiki akapfava, kudzikisa kuramba uye kuchengetedza simba.

- High-kuoma zvinhu zvinowedzera kugadzirwa kweanosvika makumi matatu%.

Chigadzirwa cheGerman chekudzokorora chirimwa chakaona kusvetuka kwe22% mukubudirira uye kudonha kwe14% mukushandiswa kwesimba patani mushure mekuchinja kune zvirinani blade zvinhu. Kana mashizha achigara akapinza uye akachena, muchina wese unomhanya zvirinani uye unoshandisa simba shoma.

Smart Automation uye Maitiro Kudzora

Smart otomatiki inoita kuti PE diki yezvakatipoteredza granulator itonyanya kushanda. Michina iyi inoshandisa PLC kutonga masisitimu uye yekubata zvikirini kuti ishande nyore. Automation zvinhu zvinosanganisira:

- Auto feeding control yekudzikama kuyerera kwezvinhu.

- Dual chiteshi mafirita masisitimu anoita kuti vashandisi vachinje zviratidziro pasina kumira.

- Back-flush sefa masisitimu ekuti otomatiki tsvina inoraswa.

- Kugadzirisa otomatiki kwepelletizing banga kumhanya uye kudzvanywa kwemayunifomu pellets.

- Pamhepo kugadzirisa matambudziko uye parameter optimization kuburikidza negore kutonga.

Zano: Smart otomatiki haingochengetedze simba chete asi zvakare inoderedza kudiwa kwebasa remaoko. Vashandi vanogona kutarisa kune mamwe mabasa apo muchina unobata magadzirirwo enguva dzose.

Magadzirirwo akabatanidzwa anosanganisa shredders, compactors, uye extruder mune imwe system. Iyi setup inoita kuti maitiro arambe achimhanya pasina kuzorora kwenguva refu, izvo zvinoreva kushoma kupera simba uye kubuda kwepamusoro.

Waste Heat Kudzoreredza uye Kushandiswa

PE madiki ezvakatipoteredza granulators haaregi kupisa kwakakosha kuenda kunoparadza. Panguva yekushanda, michina iyi inogadzira kupisa. Panzvimbo pekurasikirwa nayo, iyo system inotora uye inodzoreredza kupisa uku kune mamwe matanho ekugadzira, senge pre-kupisa zvinhu kana kudziya nzvimbo yebasa. Iyi nzira inodzikisira kudiwa kwekuwedzera kudziyisa michina uye kuderedza kushandiswa kwesimba rose.

- Waste heat recovery inotsigira zvibodzwa zvezvakatipoteredza nekudzikisa kuburitsa gasi regreenhouse.

- Kushandisazve kupisa kunobatsira vagadziri kusangana nesimba rakasimba uye zvakatipoteredza.

- Iyo nzira zvakare inochengeta mutengo wekushanda uchidzika, zvichiita kuti ma granulator ive smart investimendi.

Nekubatanidza izvimaitiro ekuchengetedza simba, PE diki yezvakatipoteredza granulator inoisa mwero mutsva wekubudirira uye kusimba mukudzoreredza kwepurasitiki.

Mabhenefiti Anoshanda uye Nezvakatipoteredza Impact

Lower Operational Energy Consumption

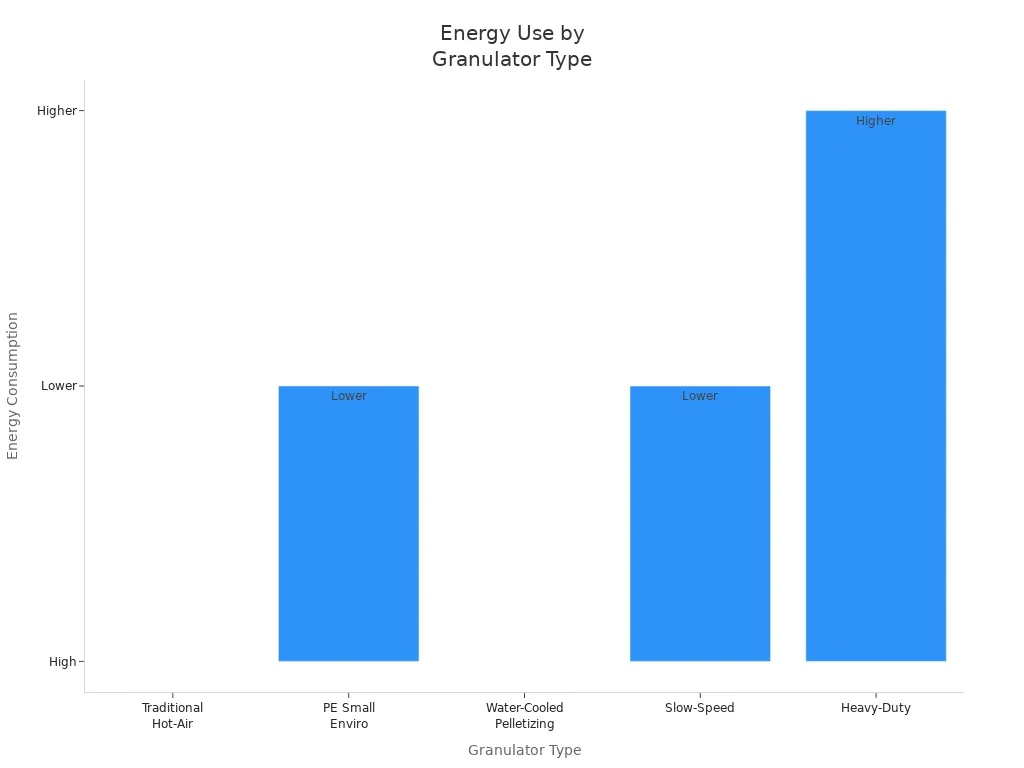

PE madiki ezvakatipoteredza granulator anomira kunze kwekushandisa kwavo kwakaderera simba. Mazhinji echinyakare granulator, semhepo inopisa kana mvura-yakatonhodzwa masisitimu, anoshandisa mamwe magetsi uye anokonzeresa kusvibiswa. Tafura iri pazasi inoratidza kuti akasiyana granulator marudzi anofananidzwa sei:

| Granulator Type | Kushandiswa Kwemagetsi | Environmental Impact | Operational Notes |

|---|---|---|---|

| Traditional Hot-Air Plastic Granulators | High | Kusvibisa kunokosha | Kupfuura 75% yemidziyo; inoda kuvandudzwa |

| PE Diki Inoshamwaridzana Nezvakatipoteredza Granulators | Kuderera nekuda kwekutonhora kwemhepo uye kushanda kwakaderera | Kuburitswa kwakaderedzwa nekuda kwekuchengetedza simba | Inoshandisa renewable zviwanikwa uye kutambisa kupisa kupora |

| Mvura-Yakatonhodzwa Pelletizing Systems | High (mvura nemagetsi) | Mutoro wezvakatipoteredza kubva pakushandisa mvura | Kukura kwetsoka, kushanda kwakaoma |

| Slow-Speed Granulators | Lower | Kudzika ruzha uye kupfeka | Yakanakira zvikamu zvidiki, padivi pe-the-press kushandiswa |

| Heavy-Duty Granulators | Higher | Yakakwira nekuda kwekubuda | Zvemidziyo yakaoma; simba shoma rinoshanda |

Air-yakatonhodzwa, yakaderera-tembiricha kushanda kunobatsira aya granulator kushandisa simba shoma. Vanodarikawo danho rekuomesa, iro rinochengetedza simba rakawanda.

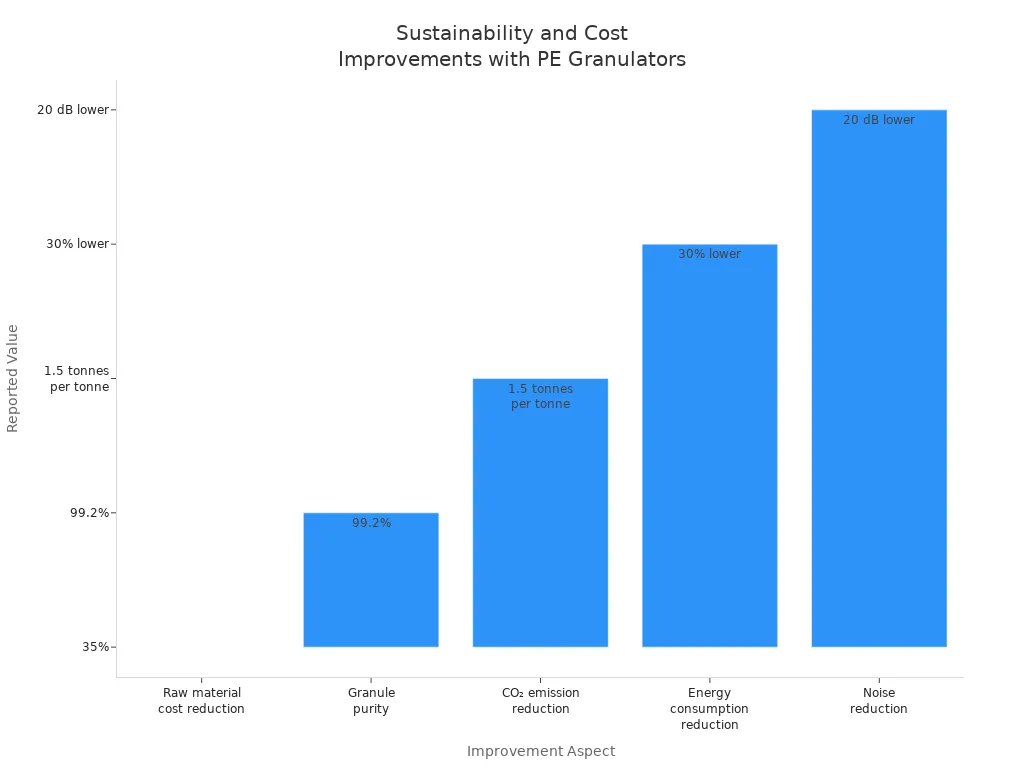

Yakaderedzwa Carbon Footprint uye Kutevedzera

Michina iyi inobatsira makambani kuderedza kabhoni yavo. Vanoshandisa simba shoma uye vanodzokorora tsvina yepurasitiki panzvimbo, zvinoreva marori mashoma mumugwagwa uye kusvibiswa kushoma.Michina midiki yepurasitiki yekudzokorodzachengetedzawo marara kubva pamarara. Nekushandura mapurasitiki ekare kuita mapepa matsva, vanoderedza kudiwa kwezvinhu zvitsva. Makambani mazhinji zvino anosangana nemitemo yakasimba yezvakatipoteredza nekuda kwekusimudzira uku.

Cherechedza: Mugadziri wemotokari wekuGermany akachengetedza mazana matatu ematani epurasitiki matsva gore rega rega nekudzoreredza marara akawanda nemagranulator madiki.

Kuchengetedza Mutengo uye Kubudirira Kwekugadzira

Vagadziri vanoona kuchengetedza chaiko nemagranulator aya. Yakakwirira-inoshanda mota uye smart otomatiki inodzikira magetsi mabhiri. Basa shoma remaoko rinoreva zvikanganiso zvishoma uye nguva shoma. Tafura iri pazasi inoratidza kuti anzira yakarongeka inowedzera kushanda nesimba uye purofiti:

| Danho | Tsanangudzo | Zviito Zvikuru |

|---|---|---|

| Planning | Tsanangura zvinangwa uye KPIs | Seta zvibodzwa zveSMART, govera zviwanikwa |

| Kuuraya | Ita shanduko mune inodzorwa env | Pilot mapurojekiti, simbisa kudzidziswa |

| Evaluation | Tarisa mafambiro uye unganidza mhinduro | Shandisa data analytics, gadzirisa sezvinodiwa |

| Kuwedzera | Chikero maitiro akabudirira | Batanidza zvidzidzo zvakadzidzwa, dzidzisa |

Kudonha kwe20% munguva yekutenderera kunogona kutungamirira kune imwe mari. Kurasa kupisa kupora uye kushandiswa kwesimba kwakaderera zvakare kunoderedza mari.

Compact Size uye Space Efficiency

Iyo compact dhizaini yeaya granulator inochengetedza yakakosha pasi nzvimbo. Mashopu madiki nenzvimbo dzekudhindisa anogona kudzikwana pasina kuchinja marongero adzo. Vashandi vanozviwana zviri nyore kuchengetedza nekuchenesa, zvinoreva kuti nguva shoma. Iyo modular setup inotsigira yakavharwa-loop kudzokorodza, zvichiita kuti maitiro ese ashande uye arambe aripo.

Zano: Mutsindo mudiki unoreva nzvimbo yakawanda yezvimwe midziyo kana kuwedzera kweramangwana.

PE madiki ezvakatipoteredza granulator anoisa mwero mutsva wekushandisa simba muna 2025. Vagadziri vanoona mabhenefiti chaiwo:

- Mari yakaderera uye kuraswa kushoma

- Mitemo yepamusoro yekudzokororazve

- Tsigiro yezvinangwa zvekusimudzira

- Kubhadhara nekukurumidza uye kutevedzera kwakasimba

FAQ

Iyo PE diki yezvakatipoteredza granulator inobatsira sei kuchengetedza simba?

Iyo granulator inoshandisa yakakwirira-inoshanda mota uye yakangwara otomatiki. Aya maficha anocheka kushandiswa kwemagetsi uye kuchengetedza kugadzira kwakadzikama.

Zano: Zvidzoreso zvine hungwaru zvinoita kuti vashandisi vagadzirise marongero nekukasira kuti vachengetedze zvakanyanya.

Ko mashopu madiki anogona kushandisa iyi granulator?

Hungu, vanogona. Iyo compact size inokodzera nzvimbo dzakasimba. Vashandi vanoona zviri nyore kuisa nekuchengetedza.

- Inokodzera mitsetse midiki yekugadzira

- Nyore kushanda

Ndezvipi zvinhu zvinogona PE diki yezvakatipoteredza granulator process?

InobataPE nemamwe mapurasitiki. Muchina uyu unoshanda nemazvo pakudzoreredza tsvina yepurasitiki kuita mapepa matsva.

| Material Type | Yakakodzera Granulation? |

|---|---|

| PE | ✅ |

| PP | ✅ |

| PVC | ✅ |

Nguva yekutumira: Aug-14-2025