Shear simba rinoita basa rakakosha mukushanda kwepurasitiki twin screw extruder. Rinoreva simba rinokonzera kuti zvidimbu zvezvinhu zvitsvedzeke zvichipesana, zvichikanganisa zvakanyanya zvimiro zvenyama. Semuenzaniso, mauto eshear akakwira anowedzera kusanganisa uye kugovera kupisa. Mune aTwin Plastic Screw Barrel, dhizaini yekunyunguduka inovimbisa kuyerera kwezvinhu zvakanaka uku ichideredza tembiricha spikes, sekumanikidza kwe40 bar kunogona kukwidza tembiricha ne20°C. Uyezve, aConical Twin Screw Extruder Screw Barrelinowedzera kukwidziridza maitiro aya nekuenzanisa shear simba uye throughput, nepo iyoTwin Screw Barreldhizaini inobatsira pakubudirira kwese mune extrusion process.

Nheyo dzePlastiki Mapatya Kurukura Extruder

Zvikamu zvakakosha zveExtruder

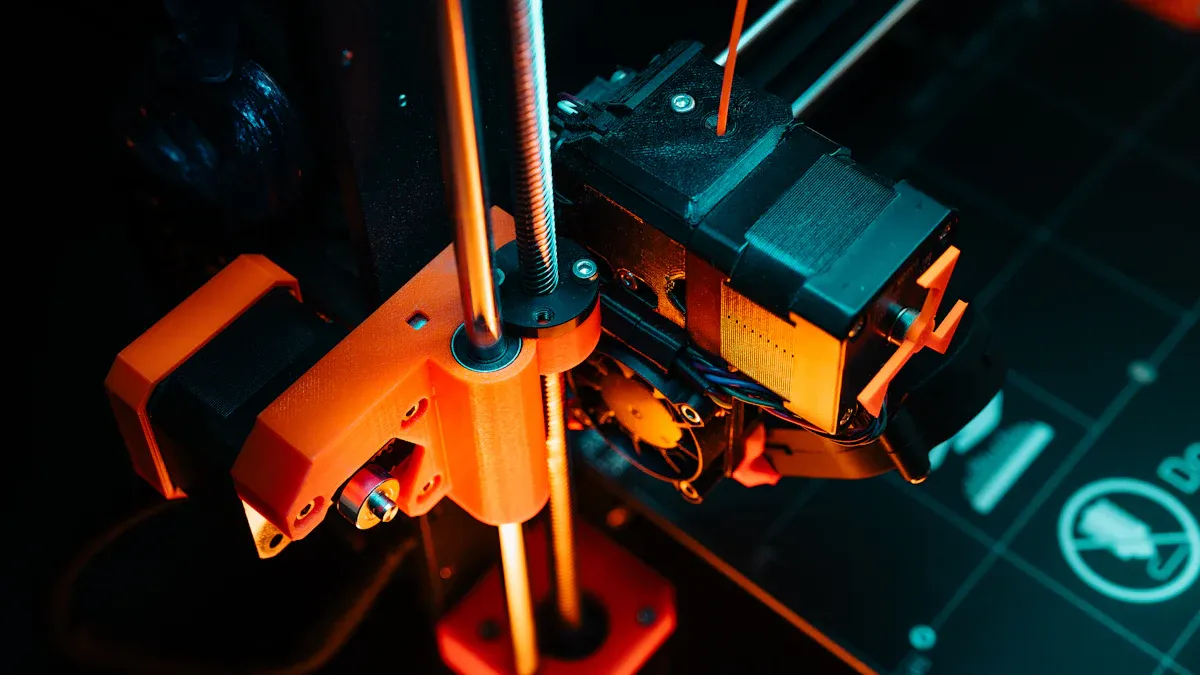

A plastiki twin screw extruderine zvinhu zvakati wandei zvakakosha zvinoshanda pamwechete kugadzira zvinhu nemazvo. Izvi zvinosanganisira:

- Hopper: Nzvimbo yekupinda iyo mbishi zvinhu zvinodyiswa muhurongwa.

- Bharel: Imba huru iyo zvinhu zvinonyungudutswa uye zvakasanganiswa.

- Screw Conveyor: Inotarisira kutakura zvinhu kuburikidza ne extruder.

- Heating System: Inopa kupisa kunodiwa kwekunyungudutsa epurasitiki makomisheni.

- Temperature Control: Inovimbisa kuenderana kugadzirisa mamiriro.

- Extrusion Head: Inoumba zvinhu kuita fomu yaidiwa sezvainobuda muextruder.

Chikamu chega chega chinoita basa rakakosha mukuona kuti extruder inoshanda mushe uye inopa yemhando yepamusoro kuburitsa. Semuyenzaniso, iyo inoshanduka screw yekumhanyisa inobvumira kunyatso kudzora pamusoro peiyo extrusion maitiro, nepo inotsiviwa inofa inogonesa kugadzirwa kweakasiyana maumbirwo uye saizi.

Basa reScrews uye Barrel muShear Force Generation

Iyo screws nedhiramu zviri pakati pekugadzira shear simba mupurasitiki twin screw extruder. Iyo screws inotenderera mukati medhiramu, ichigadzira kukweshera uye kumanikidza kunonyungudika nekusanganisa zvinhu. Zvinhu zvakadai sekumhanya kwescrew, dhayamita yekufa, uye hunhu hwezvinhu zvinopesvedzera shear simba. Semuyenzaniso:

| Parameter | Kufurira paShear Force Generation |

|---|---|

| Kukurura Speed | Kumhanya kwepamusoro kunowedzera kubuda uye kuparara kwesimba, kuwedzera shear simba. |

| Die Diameter | Madhayamita akakura anoderedza kudzvanywa uye simba, zvichikanganisa shear simba. |

| Muitiro Wezvinhu | Shear-kutetepa zvinhu zvinoratidza kuderera uye simba zvichienzaniswa neNewtonian fluid. |

Kudyidzana uku kunovimbisa kushanda zvakanaka kwezvinhu uye kusanganiswa kwakafanana.

Material Flow Dynamics muExtruder

Material flow dynamics mupurasitiki twin screw extruder inotarisisa kunaka kwekusanganisa uye chigadzirwa chekupedzisira. Nzira dzepamusoro dzemakomputa, dzakadai seCFD, dzakawedzera kunzwisisa kweaya masimba. Tekinoroji senge vhoriyamu-ye-mvura (VOF) uye nhanho-yakaiswa nzira dzinoteedzera mvura inopindirana panguva yekusanganiswa, kuve nechokwadi chekutonga chaiko pamusoro pemaitiro. Twin screw extruder anoshandiswa zvakanyanya mumaindasitiri akaita semishonga nekuda kwehukuru hwavo hwekusanganisa kugona. Pasi pemamiriro akajairwa (30 kg/hr, 200 rpm), kudzvanywa mune imwe kamuri yakaita seC kunosvika 2.2 MPa, nekudonha kwemadonhwe e0.3 MPa munzvimbo yepakati uye 0.5 MPa mune reverse screw element. Aya ma metrics anosimbisa kugona kweiyo extruder mukubata zvinhu zvakasiyana.

Shear Force Mechanism muTwin Screw Extrusion

Chizvarwa cheShear Force muExtrusion process

Simba rekugera mutwin screw extrusion process inomuka kubva mukudyidzana pakati pemakona anotenderera nedhiramu rakamira. Sezvo ma screws achitenderera, anogadzira kukweshera uye kudzvanywa, zvichiita kuti zvinhu zviparare nekuyerera. Iyi deformation inogadzira shear masimba anoita basa rakakosha mukunyungudusa, kusanganisa, uye homogenizing zvinhu. Iyo screws 'intermeshing dhizaini inovimbisa kuti zvinhu zvinosangana nekuveura kwakafanana mukati mekuita.

Kuongororwa kwenhamba uchishandisa nzira yevhoriyamu-ye-fluid (VOF) yakaratidza nzira dzehydrodynamic dzakabatanidzwa mukuita uku. Inotaridza kuti kugera masimba, viscosity ratios, uye mhirizhonga zvinokanganisa sei microstructure yeimmiscible alloys panguva yekusanganiswa. Izvi zvakawanikwa zvinosimbisa kukosha kwemasimba ekuveura pakuona rheological maitiro uye kuita kwese kweiyo extrusion process.

Zvidzidzo zvekuyedza zvinowedzera kutsigira nzira iyi. Semuyenzaniso, tsvakiridzo yepolypropylene-clay nanocomposites yakaratidza kuti mapatya screw extruder anowana kupararira kwepamusoro kana zvichienzaniswa nekamwe screw extruder. Izvi zvinokonzerwa nemasimba ekumusoro ekugera anogadzirwa mumapatya screw masisitimu, ayo anosimudzira exfoliation yezvigadzirwa uye anovandudza ma mechanic uye anopisa zvivakwa.

Zvinhu Zvinokanganisa Shear Force

Zvinhu zvakati wandei zvinopesvedzera chizvarwa uye ukuru hwesimba rekugera mupurasitiki twin screw extruder. Izvi zvinosanganisira screw speed, screw geometry, uye viscosity yezvinhu.

- Kukurura Speed: Kuwedzera screw speed inosimudza shear rate, zvichitungamira kune yakakwira shear masimba. Nekudaro, kumhanya kwakanyanya kunogona kukonzera kuderera kwezvinhu kana kupisa.

- Screw Geometry: Magadzirirwo emasiruuru, anosanganisira kukwirira kwawo, kudzika kwendege, uye kupindirana kwekona, zvinokanganisa zvakananga chiito chekuveura. Semuyenzaniso, masiruuru ane ndege dzakadzama anogadzira simba rekugera rakaderera, ukuwo makona akabatikana anowedzera kugera.

- Material Viscosity: High-viscosity zvinhu zvinoda hukuru hweshear masimba kuti uwane kusanganiswa kwakakodzera uye kunyunguduka. Sezvineiwo, zvinhu zvakaderera-viscosity zvinogona kuyerera zviri nyore, zvichideredza kushanda kwechiito chekuveura.

Zvidzidzo zveStatistical zvakaongorora zvinhu izvi zvakadzama. Semuyenzaniso, tsvagiridzo yakaratidza kuti kusungirirwa kunowedzera kunowedzera zvakatevedzana nekumhanya kwescrew asi kunoderera nechiyero chekudya. Mamiriro ekugadzirisa akakwana, akadai sechiyero chekudya che 3.6 kg/h pa screw speed ye 95 rpm, wedzera tembiricha uku uchideredza kutsemuka kwefiber. Izvi zvakawanikwa zvinosimbisa kukosha kwekuenzanisa zvinhu izvi kuti zvibudirire extrusion.

Nzira dzekudzora Shear Force

Kudzora simba rekugera kwakakosha pakugadzirisa iyo extrusion maitiro uye kuve nechokwadi chakaenderana chigadzirwa mhando. Nzira dzinoverengeka dzinogona kushandiswa kutonga shear simba mune mapatya screw extruder:

- Kugadzirisa Kukurumidzira: Vashandisi vanogona kuwedzera kana kudzikisa screw kumhanya kuti vagadzirise mwero weshear uye kuzadzisa izvo zvinodiwa zvinhu zvivakwa.

- Kugadzirisa Screw Design: Kugadzira sikururu geometry, sekuchinja kukwirira kana kudzika kwendege, kunobvumira kudzora chaiko pamusoro pechiito chekugera.

- Kushandisa Shear-Thinning Models: Aya mamodheru anobatsira kufanotaura maitiro enyama pasi peakasiyana mamiriro ekugera, achigonesa zvirinani kudzora maitiro. Nekudaro, kuvimba chete neaya mamodheru kunogona kutungamira kune kushomeka kweakakosha paramita senge kudzvanywa uye viscosity.

- Kushandisa Advanced Monitoring Systems: Chaiyo-nguva yekutarisa ma parameter akadai tembiricha, kudzvanywa, uye torque inopa yakakosha manzwisisiro mukuita extrusion. Iyi data inogona kushandiswa kugadzirisa uye kuchengetedza yakakwana shear simba mazinga.

Tsvagiridzo yakaratidza kuti basa re screw mukupisa kupisa kwakakosha pakudzora shear simba. A recirculation circuit mafomu mukati me extruder, iyo inobatsira kugovera kupisa zvakaenzana uye inodzivirira kupisa kwenzvimbo. Izvi zvinogonesa kuti iyo polymer inonyunguduka zvakafanana, ichiwedzera kugona kwese kweiyo extrusion process.

Impact yeShear Force pane Material Properties

Migumisiro paKusanganiswa uye Homogeneity

Shear simba rinoita basa rakakosha mukuwana yunifomu musanganiswa uye homogeneity muzvinhu zvinogadziriswa nepurasitiki twin screw extruder. Kudyidzana kuri pakati pema screws nebarrel kunogadzira friction, iyo inofambisa kusanganiswa kwemapolymers uye additives. Iyi nzira inovimbisa kuti chigadzirwa chekupedzisira chinoratidza zvinhu zvinowirirana muchimiro chayo.

Zvidzidzo zveEmpirical zvinosimbisa akati wandei mashear force impact:

| Chikamu cheShear Force Impact | Tsanangudzo |

|---|---|

| Fiber Breakage | Kuveura mauto mune yakanyungudutswa matrix anotungamira kune fiber kuputsika, zvichikanganisa zvimiro zvechigadzirwa chekupedzisira. |

| Heat Generation | Inenge 80% yekupisa kunodiwa pakunyunguduka kunogadzirwa nekukweshana nekuda kwekugera pakati pemasikiru nedhiramu. |

| Kusanganisa Kubudirira | Dhizaini yekusanganisa nzvimbo dzine kumberi- uye reverse-inoendesa zvinhu zvinopesvedzera kudzvanywa simba uye kusanganisa kwese kunyatsoshanda. |

| Residence Time Distribution | RTD inokanganisa zvakanyanya hunhu hwechigadzirwa nekuona kuratidzwa nguva yekudziya, kudzvanywa, uye kugera. |

Pamusoro pezvo, kuwedzera kumhanya kwerotor panguva yepolypropylene-sisal kunyunguduka-kusanganisa kunokonzeresa kuparara kwefiber, kuburitsa hurefu hwefiber. Chiitiko ichi, chinocherechedzwa mumafibhi echisikigo, chinoitika nekuti shear inopatsanura mafiibhi akasungwa, ichideredza dhayamita yadzo. Izvi zvakawanikwa zvinosimbisa kukosha kwekugadzirisa simba reshear kuenzanisa kusanganisa kusanganisa uye kuvimbika kwezvinhu.

Pesvedzero paZvivakwa zveThermal uye Kugovera Kupisa

Shear simba rinokanganisa zvakanyanya kupisa zvivakwa uye kugovera kupisa panguva yeextrusion. Fiction inogadzirwa ne screws accounts inosvika 80% yekupisa kunodiwa kunyungudutsa epurasitiki makomisheni. Uku kugovera kupisa kunovimbisa kunyungudika kwakafanana uye kunodzivirira kupisa kwenzvimbo, izvo zvinogona kukanganisa kunaka kwezvinhu.

Dhizaini yeiyo extruder yekusanganisa nzvimbo inowedzera kuwedzera kupisa kutamisa. Forward- and reverse-conveying zvinhu zvinogadzira kudzvanya simba kunonatsiridza thermal conductivity. Kugovera nguva yekugara (RTD) inoitawo basa rakakosha. Zvishandiso zvakafumurwa kune anowirirana eshear masimba anosangana nekudziya kwakafanana, zvichikonzera kugadzikana kwekupisa kuri nani.

Semuenzaniso, kuenzanisa kwenhamba kunoratidza kuti mauto ekuveura anokanganisa microstructure yeimmiscible alloys panguva yekusanganiswa. Aya masimba anopesvedzera viscosity ratios uye mhirizhonga, kuve nechokwadi kunyangwe kugoverwa kwekupisa mukati mezvinhu. Zvakawanikwa zvakadaro zvinosimbisa kukosha kweshear simba mukuchengetedza thermal equilibrium panguva yeextrusion.

Kuchinja kweMechanical Properties uye Kusimba Kwezvinhu

Shear simba rinokanganisa zvakananga ma mechanical zvivakwa uye simba re extruded zvinhu. Kusiyana kwehuremu hweshear kunogona kushandura chimiro chemolecular, zvichiita kuti shanduko mukusimba kwesimba, elasticity, uye kusimba.

Tsvakurudzo yenhamba inoratidza izvi zvinokonzeresa:

- Iyo peak shear simba rekusiyana kwekona yejoint specimens inowedzera zvisina mutsetse nekunetseka kwakajairwa, nepo kusara kwesimba rekugera kunoratidza kushoma kuwirirana nejoint morphology.

- Pakudzikama kwakajairwa kushushikana, zvienzaniso zvinoratidza shear dilatancy, izvo zvinodzikira pamwero wepamusoro wekushushikana. Maitiro aya anoratidza kusawirirana kwakashata pakati pezvakajairwa uye tangential displacements.

- Maitiro ekutadza anosiyana nemakona emajoini. Nzvimbo dzakakwirira-makona dzinoratidza kutsemuka uye kugera, nepo nzvimbo dzakaderera-makona dzinoratidza kutadza kweshear munzira yekugera.

Izvi zvakawanikwa zvinosimbisa kukosha kwekudzora shear simba kuti uwane inodiwa michina zvinhu. Semuenzaniso, kugera kwakawandisa kunogona kukonzera kuparara kwefiber, kuderedza simba rezvinhu. Sezvineiwo, kuveura kusina kukwana kunogona kukonzera kusakwana kusanganisa, kukanganisa kunaka kwechigadzirwa.

Zvidzidzo Zvenyaya: Kuzvibata Kwezvinhu Pasi Kusiyanisa Mamiriro Ekucheka

Zvidzidzo zvenyaya zvinopa nzwisiso yakakosha yekuti simba rekugera rinokanganisa sei maitiro enyama. Tsvagiridzo yepolypropylene-clay nanocomposites inoratidza izvozvotwin screw extruderskuwana kupararira kwepamusoro zvichienzaniswa neayo imwe screw masisitimu. Masimba ekugera epamusoro anowedzera exfoliation, kuvandudza michina uye yekupisa zvivakwa.

Imwe ongororo yemafibhi echisikigo inoratidza kuti kugera kunoiswa panguva yekubatanidza kunopatsanura mafiibha akasungwa, zvichideredza dhayamita rawo. Iyi nzira inosimudzira homogeneity yezvinhu asi inogona kukanganisa kutendeseka kwayo kwechimiro.

Mumaindasitiri ekushandisa, optimization shear force yakaratidza yakakosha mukugadzira zvigadzirwa zvemhando yepamusoro. Semuyenzaniso, kugadzirisa screw speed uye geometry mupurasitiki twin screw extruder inova nechokwadi chekusanganisa yunifomu uye kuenderana kwezvinhu zvinhu. Izvi zvidzidzo zvenyaya zvinosimbisa kukosha kwekugadzirisa simba reshear kune chaiwo maapplication.

Optimization Strategies yePlastiki Twin Screw Extruder

Screw Dhizaini uye Configuration Magadzirirwo

Optimizing screw designyakakosha pakuvandudza mashandiro epurasitiki twin screw extruder. Magadzirirwo ekukusha geometry, senge pitch, kudzika kwendege, uye intermeshing angle, inopesvedzera zvakananga kugadzirwa kwesimba rekugera uye kuyerera kwezvinhu. Semuyenzaniso, masiruuru ane ndege dzakadzika anodzikisira kugera, ukuwo makona akabatikana achiwedzera kusanganisa.

Vashandisi vanowanzo gadzirisa screw masisitimu kuti aenderane chaiwo zvinhu zvivakwa. High-viscosity mapurasitiki anobatsirwa kubva kune screws akagadzirwa neakakura kudzika kwendege kuti afambise kuyerera kwakatsetseka. Sezvineiwo, zvinhu zvakaderera-viscosity zvinoda ma angles akasimba ekupindirana kuti ive nechokwadi chekuveura kwakaringana. Izvi zvigadziriso zvinovandudza homogeneity yezvinhu uye kuderedza kushandiswa kwesimba panguva yeextrusion.

Kuenzanisa Shear Simba uye Tembiricha

Kuchengetedza chiyero pakati peshear simba uye tembiricha kwakakosha kuti uwane inopindirana extrusion mhando. Kunyanya kugera simba kunogona kutungamirira mukupisa, nepo kusakwana kweshear kunogona kukonzera kusanganiswa kusina kukwana. Kugadzirisa kudzvanywa mukati meiyo extruder kunoita basa rakakosha mukudzora aya akasiyana.

Semuyenzaniso, fomula inotaridza hukama huri pakati pekumanikidza netembiricha: ∆T (°C) = ∆P (bha) ÷ 2. Kugadzira 500 kg/a pakumanikidza kufa kwe40 bar kunogona kuwedzera tembiricha yekunyungudika ne20°C. Kubatanidza pombi yegiya kunoderedza kudzvanywa, kuderedza tembiricha spikes uye kupfeka pane discharge screws. Yakavharwa-loop pressure control inowedzera kuwedzera extrusion kugadzikana, kuve nechokwadi chekugovera kupisa kweyunifomu uye yakakwana yezvinhu zvinhu.

Tailoring Shear Force kune Chaiyo Plastic Application

Kugadzirisa simba reshear kune chaiyo maapplication kunowedzera kushanda kwezvinhu zvepurasitiki. Semuyenzaniso, kuwedzera plasticizers kuPLA macomposites anovandudza kuchinjika, kukanganisa kuramba, uye michina zvinhu. Scanning electron microscopy (SEM) mifananidzo inoratidza kuti plasticized PLA inoratidza hukuru hukuru kana ichienzaniswa neasina kuumbwa macomposites, ayo anoratidza brittle maitiro.

Flexural bvunzo dzinoratidza kuti mapurasitiki akasanganiswa ane yakaderera flexural modulus kukosha, zvichiratidza kuwedzera kushanduka. Pamusoro pezvo, kuwedzera kweplasticizers kunoderedza tembiricha yegirazi (Tg), zvichiita kuti zvive nyore kugadzirisa. Aya magadzirirwo anoratidza kukosha kwekugadzirisa shear simba kuti asangane neakasarudzika zvinodiwa zveakasiyana mapurasitiki ekushandisa.

Real-Nguva Monitoring uye Kuyera Techniques

Real-time monitoring systemsinopa ruzivo rwakakosha mukuita extrusion, zvichiita kuti vashandisi vagone kukwidziridza simba rekugera zvinobudirira. Masensa anoyera akakosha ma paramita akadai setembiricha, kudzvanywa, uye torque, ichipa chaiyo kutonga pamusoro peextrusion mamiriro.

Maitiro ekutarisa epamberi, akadai seakavharika-loop masisitimu, chengetedza zvimiro zvekumanikidza uye kudzivirira shanduko inogona kukanganisa kunaka kwechigadzirwa. Aya masisitimu anoonawo anomalies mukuyerera kwezvinhu, zvichibvumira vashandisi kugadzirisa nekukurumidza. Nekushandisa data-chaiyo-nguva, vagadziri vanovimbisa kuti epurasitiki twin screw extruder inoshanda nepamusoro-soro, ichiburitsa yemhando yepamusoro.

Shear simba rinoramba riri dombo repakona repurasitiki twin screw extrusion, kuumba zvinhu zvemukati senge kusanganisa, kugadzikana kwemafuta, uye simba remuchina. Kugadzirisa simba iri kunosimudzira kunaka kwechigadzirwa uye kushanda zvakanaka.

Kuenderera mberi hunyanzvi mushear force control inovhura mikana mitsva mukugadzira mapurasitiki. Vatsvagiri uye mainjiniya vanofanirwa kuongorora matekiniki epamusoro ekunatsiridza extrusion mhedzisiro zvakare.

FAQ

Ndeipi basa rekutanga reshear force mune twin screw extrusion?

Shear simba rinogonesa kunyungudika kwezvinhu, kusanganisa, uye homogenization. Iyo inovimbisa kuenderana kwechigadzirwa mhando nekufurira zvinopisa uye zvemagetsi zvivakwa panguva yeextrusion.

Vafambisi vangadzora sei simba rekugera mupatya screw extruder?

Vashandi vanogadzirisa screw speed, gadzirisa screw geometry, uye tarisa-chaiyo-nguva paramita senge kudzvanywa uye torque kudzora shear simba zvinobudirira.

Sei kuyera simba rekugera uye tembiricha yakakosha?

Kuenzanisa simba rekugera uye tembirichainodzivirira kuparara kwezvinhu, inovimbisa kusanganiswa kwakafanana, uye inochengetedza yakakwana extrusion mamiriro ekubuda kwemhando yepamusoro.

Nguva yekutumira: Jun-11-2025