Muchina wekugadzira jekiseni repurasitiki rinonyatso shandura plastiki mbishi kuita chaiyo, yakaoma zvimiro. Iyi nzira inopa zvikomborero zvinoshamisa:

- Kugadzira zvikamu zvakaoma kunzwisisa nehupamhi hwepamusoro-soro.

- Kuendesa inowirirana mhando uye repeatability.

- Kuderedza mari yekugadzira mukugadzira kukuru.

Madhizaini epamberi, akadai seScrew Type Injection Molding Machine uyeScrew Type Injection Molding Machine, kuwedzera kuyerera kwezvinhu uye optimize kuita. Mukuwedzera, iyoKaviri Barrel Injection Molding MachineuyeScrew Injection Molding Machinekuwedzera kuvandudza kushanda uye kubuda mukugadzira.

Injection Unit muScrew Type Injection Molding Machine

Iyo jekiseni unit muScrew Type Injection Molding Machine inoita basa rakakosha mukushandura mbishi epurasitiki pellets kuita yakanyungudutswa nekuapinza muforoma. Ichi chikamu chine zvikamu zvitatu zvakakosha: hopper, barrel, uye screw mechanism. Chikamu chega chega chinobatsira pakubudirira uye kurongeka kwemaitiro ekuumba.

Hopper

Iyo hopper inoshanda senzvimbo yekupinda yezvinhu zvakasvibirira zvepurasitiki. Iyo inobata mapepa epurasitiki uye inoadyisa mudhiramu kuti iwedzere kugadziriswa. Hopper dzemazuva ano dzinowanzo sanganisira maficha senge zvinhu zvekuomesa masisitimu kuti abvise hunyoro kubva pamapellets, kuve nechokwadi chekunyungudika kwakaringana. Nekuchengetedza kuenderana kupihwa kwezvinhu, hopper inotsigira isina kukanganiswa kugadzirwa kutenderera muScrew Type Injection Molding Machine.

Bharel

Iyo dhiramu i cylindrical chamber inogara iyo screw mechanism. Inopisa mapepa epurasitiki kusvika pakunyunguduka kwavo vachishandisa nzvimbo dzakawanda dzekudziya. Idzi nzvimbo - dzinowanzo kupatsanurwa kuita chikafu, kumashure, pakati, uye kumberi - inobvumira chaiyo tembiricha kutonga, izvo zvakakosha pakuwana yunifomu kunyungudika kunaka. Kugovera tembiricha kwakaringana mukati medhiramu kunodzivirira nyaya senge warpage, kusarongeka kwedimensional, uye kuparara kwezvinhu. Uku kungwarira kutonga kunovimbisa kuti Screw Type Injection Molding Machine inoburitsa yepamusoro-mhando kuburitsa nguva dzose.

- Tembiricha yenzvimbo yedhiramu yakakodzera yakakosha pakushanda zvakanaka.

- Zvisizvo zvigadziriso zvinogona kutungamirira kukukanganisa muchigadzirwa chekupedzisira.

- Magadzirirwo epamberi anovandudza simba rekushandisa uye kuderedza mari yekushandisa.

Screw Mechanism

Iyo screw mechanism ndiyo moyo wejekiseni unit. Inotenderera mukati medhiramu, ichisanganisa nekunyungudusa mapurasitiki epurasitiki uku ichisundira zvinhu zvakanyungudutswa mberi. Dhizaini ye screw inokanganisa zvakanyanya kunyungudika uye jekiseni maitiro. Semuenzaniso, stationaryscrew designswedzera purasitiki nekuona kuenderana kushear kuratidzwa uye vhoriyamu yekupfura. Pamusoro pezvo, zvinhu zvakaita semavharuvhu epoppet zvinopa kutonga chaiko nekudzima nekukasira kana screw yamira.

Mune ese-emagetsi Screw Type Injection Molding Machines, iyo screw mechanism inopa isingaenzaniswi kutonga pamusoro pekumhanya, kudzvanywa, uye chinzvimbo. Kunyatsoita uku kunoderedza misiyano pakati pekutenderera, kuve nechokwadi chekuzadza mareti uye saizi yepfuti. Kufambira mberi uku hakungonatsiridza kunyungudika chete asi zvakare kunosimudzira kugona kwese kwemaitiro ekuumba.

- Kubatanidza otomatiki uye marobhoti kunowedzera kuwedzera kugadzirwa.

- Magetsi-anoshanda screw madhizaini anobatsira kuchengetedza mutengo.

- Kushandiswa kwezvinhu kwakasimba kunopindirana nemaitiro emazuva ano ekugadzira.

Iyo jekiseni unit muScrew Type Injection Molding Machine inoratidza synergy yeinjiniya yepamberi uye kutonga chaiko. Zvikamu zvaro zvinoshanda pamwechete zvisina musono kuendesa kugadzirwa kwemhando yepamusoro, inoshanda, uye yakavimbika.

Clamping uye Mold Units

Iyo clamping uye mold zvikamu zvakakosha zvemuchina wepurasitiki jekiseni rekuumba. Ivo vanove nechokwadi chekuti mold inoramba yakavharwa zvakachengeteka panguva yejekiseni uye kufambisa kuumbwa kwechaiyo, yepamusoro-mhando zvikamu. Aya mayunitsi ane mold, maplatens, uye mota drive, imwe neimwe ichiita basa rakasiyana mukuumbwa.

Mold

Iyo mold inoshanda semhango umo purasitiki yakanyungudutswa inoitwa. Magadzirirwo ayo anokanganisa zvakananga kunaka uye kuenderana kwechigadzirwa chekupedzisira.Maitiro akanakisa mukugadzira moldsimbisa kukora kwemadziro euniform kudzivirira kukanganisa senge warping uye sink marks panguva yekutonhora. Shanduko dzakapfava pakati pehukobvu hwakasiyana, hunowanikwa kuburikidza nemachamfer kana mafiritsi, zvinowedzera kuwedzera kutendeseka kwechimiro.

- Ukobvu hwakakodzera hwemadziro hunodzivirira kukanganisa kwekunakisa senge kupeta nekunyura.

- Simba rechimiro rinogona kuvandudzwa nembabvu uye gussets pane kuwedzera ukobvu.

- Dhizaini Yezviedzo (DOE) maitiro anobatsira kuona kukanganisa kutanga, kuve nechokwadi chekuita kwakakwana uye kuvimbika.

Mune Screw Type Injection Molding Machine, iko kurongeka kwe mold inovimbisa kuti dhizaini yakaoma uye kushivirira kwakasimba kunowanikwa. Kugona uku kunoita kuti ive yakakodzera kugadzira zvikamu zvakaoma nemhando inowirirana.

Platens

Platens ndiwo mahwendefa makuru, akafuratira anobata mold panzvimbo uye anogovera clamping force zvakaenzana. Dhizaini yavo uye kutendeseka kwechimiro kwakakosha pakuchengetedza kurongeka kwe mold uye kuve nechokwadi chekumanikidza yunifomu panguva yejekiseni. Yakakosha tekinoroji maparamendi anopesvedzera kushanda kweplaten anosanganisira huremu huremu, kutakura-kuremerwa simba, uye kurongeka optimization.

| Parameter | Impact pane Mold Alignment |

|---|---|

| Weight Impact | Inoumba ingangoita 70% yehuremu hwese hwemuchina, inokanganisa kugadzikana uye kurongeka. |

| Kukosha Kweupfumi | Kugadzirisa dhizaini kunoderedza kushandiswa kwezvinhu, kuwedzera mutengo wakanaka. |

| Performance Impact | Inovimbisa kurongeka kwakaringana kwekuumbwa uye yunifomu yekumanikidza kugovera, yakakosha pakugadzirwa kwemhando yepamusoro. |

| Structural Optimization | Inokwidziridza saizi, chimiro, uye kugoverwa kwezvinhu kuitira kurongeka kuri nani. |

| Load-Bearing Capacity | Inovandudza kusimba uye inotsigira mold alignment pasi pekunetseka kwekushanda. |

Mune Screw Type Injection Molding Machine, maplatens anobatsira mukukwanisa kwemuchina kuburitsa zvikamu zvine huremu hwepamusoro. Dhizaini yavo yakasimba inovimbisa kusimba uye kuita kwakaringana, kunyangwe pasi pemasimba ekumanikidza.

Motor Drive

Iyo mota dhiraivha inopa simba iyo clamping mechanism, ichigonesa mold kuvhura uye kuvhara nemazvo. Inoita basa rakakosha mukuchengetedza kumhanya uye kurongeka kweiyo clamping process.Madhiraivha emazuva ano, kunyanya mumakina-ese-magetsi, inopa yakawedzera kudzora pamusoro pesimba rekumanikidza uye chinzvimbo. Kunyatsoita uku kunoderedza kupfeka pa mold uye kuderedza nguva dzekutenderera, kuvandudza kushanda kwese.

Madhiraivha emagetsi anoshanda nesimba anobatsirawo pakuchengetedza mari uye kuchengetedza. Nekugadzirisa mashandisirwo emagetsi, vanoenderana nemaitiro emazuva ano ekugadzira anoisa pamberi pebasa rezvakatipoteredza. Mune Screw Type Injection Molding Machine, mota dhiraivha inovimbisa kushanda isina musono, inotsigira yakakwirira-kumhanya kugadzirwa pasina kukanganisa kunaka.

Zano:Kugara kugadziridzwa kwemota dhiraivha kunogona kuwedzera hupenyu hwayo uye kudzivirira isingatarisirwe nguva yekudzikira, kuve nechokwadi chekusakanganiswa kugadzirwa.

Iyo yekusungirira uye mold zvikamu zvinoratidza synergy yeinjiniya uye nemazvo mumashini epurasitiki ekuumba majekiseni. Dhizaini yavo uye kushanda kwavo kunopesvedzera zvakananga kugona kwemuchina kuburitsa zvikamu zvemhando yepamusoro zvinobudirira uye nekuvimbika.

Kudziisa uye Temperature Control Systems

Kudziya kwakanaka uye tembiricha yekudzora masisitimu akakosha pakuchengetedza hunhu uye kuenderana kwemajekiseni epurasitiki ekuumba maitiro. Aya masisitimu anovimbisa kuti zvinhu zvepurasitiki zvinosvika painonyungudika uye kuti tembiricha ye mold inoramba yakagadzikana mukati mekutenderera.

Barrel Heaters

Midziyo inodziyatamba basa rakakosha mukunyungudutsa maplastic pellets kune yavo yakanyanya tembiricha. Ivo vanoshandisa akawanda ekudziya nzvimbo kuti vawane chaiyo tembiricha kutonga, izvo zvakakosha kune yunifomu kunyungudika mhando. Kushanda tembiricha manejimendi inosimudzira kugona kwesimba uye inonatsiridza kupera kwepasi kwezvikamu zvakaumbwa.

- Kudzora kwakaringana tembiricha yebhari kunodzivirira kuparara kwezvinhu, kunyanya panguva dzekugara kwenguva refu.

- Kuchengeta tembiricha yakanyungudika inosvika 490 ° F inova nechokwadi chekuyerera kwezvinhu uye kunoderedza hurema.

- Kuchinja kwekushisa kwembiya kunogona kukanganisa kunaka kwechigadzirwa, zvichiita kuti kunyatsotarisisa kuve kwakakosha.

Yepamberi dhizaini madhizaini anowanzo batanidza magetsi-anoshanda ekudziya zvinhu, kudzikisa mutengo wekushanda uchichengetedza kushanda kwepamusoro. Aya maficha anowirirana nemaitiro emazuva ano ekugadzira anoisa pamberi pekuchengetedza uye kushanda nesimba.

Mold Heaters

Mold heaters inodzora tembiricha ye mold, ichivimbisa inowirirana chikamu chemhando uye kuderedza kutenderera nguva. Ukobvu hwezvinhu zve mold zvinonyanya kukanganisa kupisa kwemazinga. Zvikamu zvakakora zvinochengeta kupisa kwenguva yakareba, nepo zvikamu zvitete zvinotonhora nekukurumidza. Kugadzirisa mold heater marongero zvichienderana nekukora kwezvinhu kunodzivirira nyaya dzakaita senge warping uye inova nechokwadi chekugovera tembiricha yakafanana.

Scientific Molding matekiniki anowedzera kukwirisa mold heater kuita. Idzi nzira dzinoderedza nguva dzekutanga, kuderedza zvirahwe, uye kuwedzera maitiro ekuita. Nekuchengetedza chaiyo mold tembiricha, vagadziri vanowana purofiti yepamusoro uye kugona.

Temperature Control Mechanism

Thetembiricha yekudzora michinainochengetedza kugadzikana uye kurongeka panguva yekuumbwa. Mazano epamberi, akadai seanyanzvi anochinjika fuzzy control, sanganisa echinyakare PID kudzora ane fuzzy logic kukwirisa mbiya tembiricha. Iyi nzira inoderedza overshoot uye oscillation, inovandudza maitiro ese ehurongwa.

| Kudzora Strategy | Tsanangudzo |

|---|---|

| Nyanzvi Inogadziriswa Fuzzy Kudzora | Inosanganisa nyanzvi, fuzzy, uye PID kudzora kwekusimudzira kugadzikana uye chokwadi. |

| PID Kudzora | Nzira yechinyakare inowanzoita overshoot uye oscillation. |

| Model Predictive Control | Inoteedzera kumhanya kwejekiseni, inonatsiridza iko kurongeka mukuumba maitiro. |

Mamodheru ekudzidza emuchina, akadai seasina kurongeka sango algorithms, zvakare anobatsira mukuita simba nekuona zvakakosha zvinokanganisa mashandisirwo esimba. Izvi zvitsva zvinogonesa vagadziri kuti vaenzanise kushandiswa kwesimba nechikamu chemhando, zvichiwedzera kusimbaradzika kwekuita kwejekiseni kuumba.

Hydraulic uye Control Units

Iyo hydraulic uye control unit zvinhu zvakakosha zvemushini wepurasitiki jekiseni rekuumba. Aya masisitimu anoshanda pamwechete kuti ave nechokwadi chekushanda chaiko, kuita kwakanaka, uyekuenderana chigadzirwa chemhando.

Hydraulic System

Iyo hydraulic system inopa simba rekufamba kwejekiseni uye machira ekugadzirisa. Inogadzira simba rinodiwa kupinza purasitiki yakanyungudutswa muforoma uye kuchengetedza iyo clamping pressure panguva yekuumba. Mapombi eHydraulic, mavharuvhu, uye masilinda anoumba musimboti weiyi sisitimu, achiunza inodzorwa uye yakavimbika kuita.

Yemazuva ano hydraulic masisitimu anosanganisira epamberi matekinoroji kukuwedzera kushanda zvakanaka. Variable displacement pombi inogadzirisa kuyerera kunoenderana nezvinodiwa nemuchina wekushanda, kuderedza kushandiswa kwesimba. Pamusoro pezvo, mavharuvhu akaenzana anopa kutonga kwakaringana pamusoro pekumanikidza uye kuyerera, kuve nechokwadi chekufamba kwakanaka uye kwakaringana. Zvinhu izvi zvinoita kuti muchina ukwanise kugadzira zvidimbu zvemhando yepamusoro zvine tsvina shoma.

Zano:Kugara uchigadzirisa zvinhu zve hydraulic, sekutarisa kudonha uye kutarisa mhando yemafuta, zvinogona kuwedzera hupenyu hwehurongwa uye kudzivirira kuderera.

Control Panel

Iyo control panel inoita sehuropi hwemushini wekuumba jekiseni. Inotarisisa uye inoronga ese mabasa emuchina, ichiva nechokwadi chekushanda kwakakwana. Yakashongedzerwa nemasensor, iyo control panel inounganidza chaiyo-nguva data pane yakakosha paramita senge tembiricha, kudzvanywa, uye chinzvimbo. Semuyenzaniso:

- Masensa anoyera uye anopa mhinduro pane tembiricha uye kumanikidza.

- Mhete membrane sensors inova nechokwadi chezviyero zvechinzvimbo uchishandisa strain gauge maseru.

Mamodheru ekudzidza emuchina akabatanidzwa mune control panel inowedzera kuwedzera kugona kwayo. Aya mamodheru anofanotaura chikamu chemhando maparamendi senge goho kushushikana uye modulus, optimize magadzirirwo ekugadzirisa mhedzisiro inowirirana. Zvakawanikwa zvekuyedza zvinosimbisa aya mamodheru nekuenzanisa hunhu hwakafanotaurwa nemhedzisiro chaiyo, zvichisimbisa kugona kwavo mukuvandudza kugadzirwa kwekugadzira.

Iwo ma hydraulic uye ekudzora mayunitsi anoratidza synergy yemakanika uye dhijitari tekinoroji, kuve nechokwadi chechokwadi uye kuvimbika mumashini epurasitiki ekuumba majekiseni.

Kudyisa uye Ejection Mechanisms

Feeding Unit

Thefeeding unitinogonesa kuwanikwa kwakafanana kwemidziyo yepurasitiki kumuchina wekuumba jekiseni. Iyo inowanzo sanganisira hopper uye screwing screw. Iyo hopper inochengeta epurasitiki pellets uye inoatungamira mudhiramu, umo zvinhu zvinonyungudika. Simba rinokwevera pasi uye kudzorwa kudzungudza kunofambisa kufamba kwakatsetseka kwepellets, kudzivirira kuvharika kana kukanganisa panguva yekugadzira.

Zvikamu zvemazuva ano zvekudyisa zvinowanzo sanganisira zvemhando yepamusoro senge zvinhu zvekuomesa masisitimu. Aya masisitimu anobvisa hunyoro kubva pamapellets, izvo zvakakosha pakuchengetedza kunyunguduka kwemhando uye kudzivirira kukanganisa mune yekupedzisira chigadzirwa. Pamusoro pezvo, otomatiki nzira dzekudyisa dzinowedzera kushanda zvakanaka nekuwiriranisa kupihwa kwezvinhu nekumhanya kwemuchina wekushanda. Uku kuwiriranisa kunoderedza kuparara kwezvinhu uye kunovimbisa kusakanganiswa kutenderera kwekugadzira.

Ejection Unit

Theejection unitinoita basa rakakosha mukubvisa chikamu chakaumbwa kubva mugomba mushure mekutonhora. Inoshandisa ejector mapini, mahwendefa, kana kuputika kwemhepo kuburitsa chigadzirwa chakapedzwa pasina kukanganisa. Kunyatsoita ejection nguva uye simba kwakakosha kuchengetedza kutendeseka kwechikamu chakaumbwa uye kudzivirira kukanganisa senge warping kana kuputika.

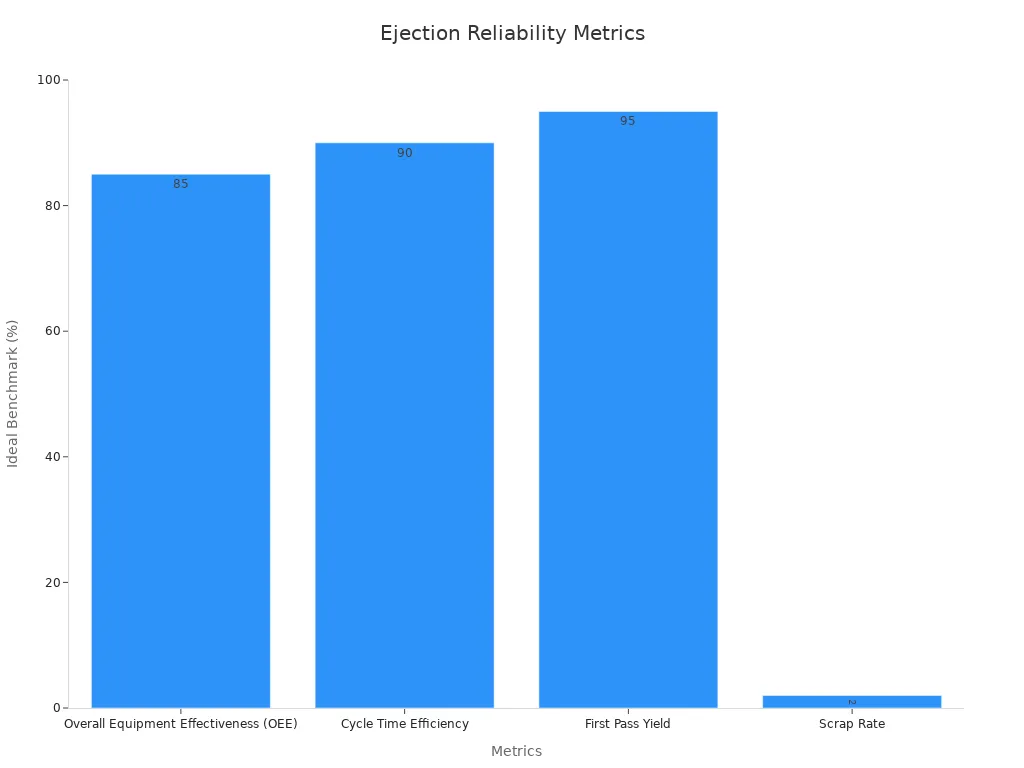

Yakavimbika ejection zvikamu zvakanyanya kuderedza kugadzirwa kutenderera nguva. Metrics akadai seOall Equipment Effectiveness (OEE), Cycle Time Efficiency, uye First Pass Yield (FPY) inosimbisa mashandiro avo. Semuyenzaniso:

| Metric | Tsanangudzo | Ideal Benchmark |

|---|---|---|

| Zvose Zvishandiso Zvinoshanda (OEE) | Inoyera kubudirira kwekugadzira; zvakaverengerwa kubva pakuwanikwa, kuita, uye kunaka. | ~85% |

| Cycle Time Kubudirira | Inoteedzera nguva yekupedzisa kutenderera kumwe kwekugadzira; nguva dzakaderera dzinowedzera throughput. | 90% kana kupfuura |

| First Pass Yield (FPY) | Pezana yezvigadzirwa zvakaitwa nemazvo nguva yekutanga; maitiro epamusoro anoratidza maitiro anoshanda. | >95% |

| Scrap Rate | Muzana wezvinhu zvakaraswa; mitengo yakaderera inowedzera purofiti. | <2% |

Yepamberi ejection masisitimu anobatanidza masensa kuti atarise uye kugadzirisa ejection simba zvine simba. Aya magadzirirwo anovimbisa kuenderana chikamu chemhando uku uchidzikisa kupfeka pane mold uye zvinhu zvemuchina. Kugara kuchengetwa kweiyo ejection unit inowedzera kuwedzera kuvimbika kwayo uye kunowedzera hupenyu hwayo hwekushanda.

Muchina wekugadzira jekiseni repurasitiki unobatanidza zvinhu zvepamberi kuendesa kuita kwakasarudzika. Chikamu chega chega chinobatsira mukugadzirwa kwakanaka, kunaka, uye kuvimbika. Kuziva masisitimu aya kunopa mhedzisiro yakakwana.

| Metric | Tsanangudzo |

|---|---|

| Kubudirira Kwekugadzira | Inotaridza mashandurirwo anoita mbishi zvinhu kuita zvigadzirwa zvakapedzwa. |

| Scrap Rate | Inotaridza huwandu hwekugadzirwa kusingaenderane nemhando yemhando. |

| Machine Downtime | Inokanganisa kugadzirwa kwakanaka uye mutengo wekushandisa, wakakosha pakuita pundutso. |

Kunzwisisa ma metrics aya kunosimbisa basa remuchina mukuwana zvinoenderana, zvemhando yepamusoro kubuda.

FAQ

1. Ndezvipi zvinhu zvinogona kushandiswa mumashini epurasitiki ekuumba majekiseni?

Plastic jekiseni rekugadzira michina inogadzira thermoplastics seABS, polypropylene, uye nylon. Ivo zvakare vanobata engineering mapurasitiki akadai se polycarbonate uye PEEK.

2. Kudzora tembiricha kunobata sei kunaka kwechigadzirwa?

Kunyatso kudzora tembiricha kunovimbisa yunifomu kunyunguduka kunaka, kunoderedza kuremara, uye kunonatsiridza chiyero chechokwadi. Iyo inodzivirira kuparara kwezvinhu panguva yakawedzera kutenderera kutenderera.

3. Ndeapi maitiro ekugadzirisa anovandudza kushanda kwemichina?

Kugara uchizora, hydraulic system cheki, uye kucheneswa kwemayuniti ekudyisa kunodzivirira kupera uye kupera nguva. Monitoring sensors inova nechokwadi chekushanda kwakafanana uye inowedzera hupenyu hwemuchina.

Nguva yekutumira: May-28-2025