Pandinoona kukuvara kwepasi kunoonekwa, kuvharika kunodzokororwa, kana kusawirirana kwemhando yechigadzirwa mune yangu Parallel Twin Screw Barrel YeExtruder, ndoziva yave nguva yekufunga kutsiva. Kukurumidza kuona kunochengetedza mari uye kunoita kuti kugadzirwa kurambe kuchifamba zvakanaka. Ndinogara ndichiongorora zvanguTwin Plastic Screw Barrel, Conical Mapatya Anokurisa Mapatya,uyeMapatya Kukurunga Extruder Barrelsnokuda kwezviratidzo izvi zvinonyevera.

Kunyanya Kupfeka muParallel Twin Screw Barrel YeExtruder

Inooneka Surface Kukuvadza

Pandinoongorora zvanguParallel Twin Screw BarrelKune Extruder, ndinotarisa zviratidzo zvakajeka zvekukuvara kwepamusoro. Ini ndinowanzo kuona magirofu akadzika pane screw zvinhu, dzimwe nguva anosvika 3 mm. Kukuvadzwa kwakanyanya kwemuchanicha pamusoro pemukati mebhodhoro kunomira pachena ipapo. Ini zvakare ndinotarisa kune makatsemuka pane screw shaft tip uye chero kukuvadza kune visco-chisimbiso mhete. Dzimwe nguva, ini ndinocherekedza kudengenyeka kusati kwatadza. Aya maratidziro ekunyevera anondiudza kuti dhiramu kana screws zvingada kutsiviwa munguva pfupi.

- Kukuvadza kwakanyanya kwemuchina mukati medhiramu

- Kudzika kwakadzika pane screw zvinhu (kusvika 3 mm)

- Kubvisa kubva pakupfeka, dzimwe nguva kusvika 26 mm

- Kutsemuka pane screw shaft tip kana yakakuvadzwa visco-seal ring

- Zvisina kujairika vibration mazinga asati akundikana

Bharel Diameter Shanduko

Ndinogara ndichiyera dhayamita yedhiramu kuti nditarise kupera. Zviyero zveindasitiri zvinoratidza kuti kushivirira kunogamuchirika kwedhiramu kuri pakati pe0.1 ne0.2 mm (0.004 kusvika 0.008 inches). Ndikaona dhayamita rachinja kudarika miganhu iyi, ndinoziva kuti dhiramu rasakara. Heino chirevo chekukurumidza:

| Chikamu | Wear Tolerance (mm) | Wear Tolerance (inches) |

|---|---|---|

| Chikururu | 0.1 | 0.004 |

| Bharel | 0.1 kusvika 0.2 | 0.004 kusvika 0.008 |

Kuwedzera Kucheneswa-ku-Barrel

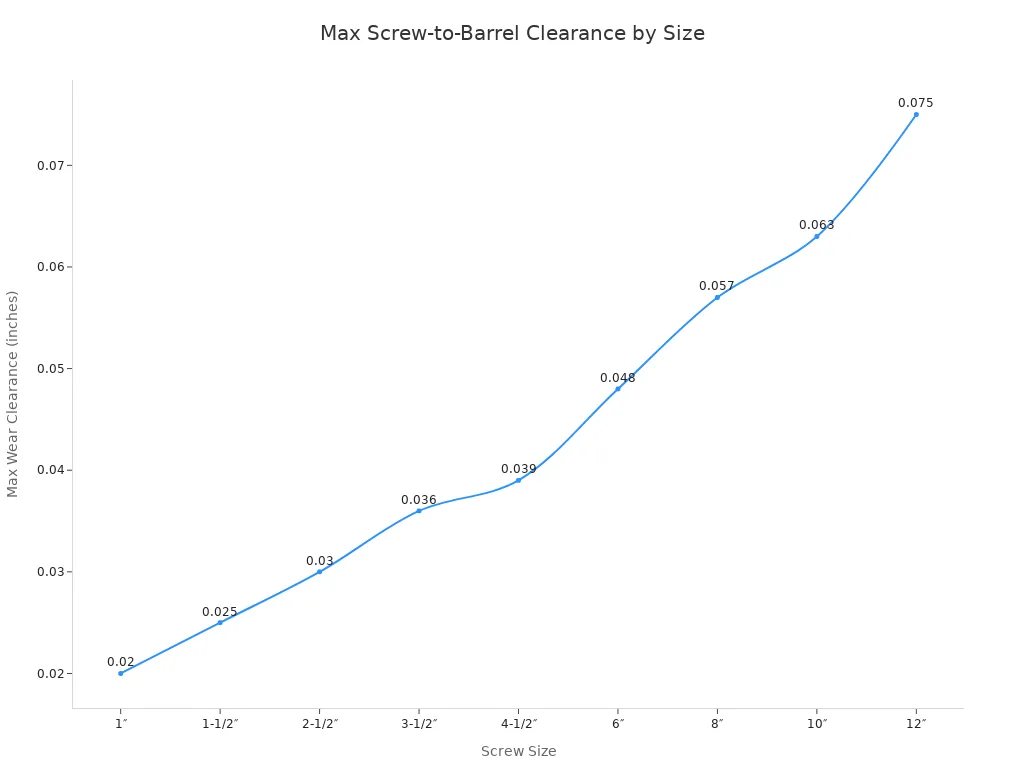

Ini ndinoteerera zvakanyanya kune gap riri pakati pe screw ne mbiya. Kana iyi clearance ikakura zvakanyanya, matambudziko anotanga kuoneka. Iyo chati iri pazasi inoratidza iyo yakanyanya kukurudzirwa kubvumidzwa kune akasiyana screw saizi:

Kana gaka richiwedzera, ini ndinoona kuwedzera kuyerera uye kubuda kwepurasitiki. Izvi zvinoita kuti kudzvanywa uye vhoriyamu ichinjike. Iyo plastiki inogona kupisa, iyo inokuvadza chigadzirwa chemhando. Ndinowanzoda kuwedzera kumhanya kwemuchina uye kushandiswa kwesimba kuti uenderane. Mukaha mudiki unochengeta zvese zvakavharwa uye zvinobudirira, asi mukaha mukuru unotungamira mukudonha uye kuderera kwekubuda. Kana ndikaona nyaya idzi, ndoziva yangu Parallel Twin Screw Barrel YeExtruder inoda kutariswa.

Yakaderedzwa Kushanda KweParallel Twin Screw Barrel YeExtruder

Lower Output Rates

Kana kuita kwe extruder yangu kunodonha, ndinozviona ipapo ipapo. Muchina unogadzira zvinhu zvishoma munguva imwe chete yenguva. I check theParallel Mapatya Kurukura Barrel For Extrudernokuda kwezviratidzo zvekupera. Masiruuru akasakara kana madhiramu anononotsa kufamba kwepurasitiki. Izvi zvinoreva kuti ndinowana zvigadzirwa zvishoma zvakapedzwa awa yega yega. Dzimwe nguva, ndinoona hopper ichigara yakazara kwenguva yakareba kupfuura nguva dzose. Izvi zvinondiudza kuti muchina haugone kuenderana nezvinodiwa.

Isingaenderani Chigadzirwa Hunhu

Ndinogara ndichitarisa shanduko mumhando yezvigadzirwa zvangu. Kana ndikaona nzvimbo dzakakasharara kana zvimiro zvisina kuenzana, ndinoziva kuti pane chakaipa. Madhiramu akasakara uye screws zvinogona kukonzera kusanganisa kusanganisa uye kunyungudika zvisina kuenzana. Izvi zvinotungamira kumatambudziko senge kunyungudika kuputsika kana kufa kuvaka-up. Heino tafura inoratidza zvakajairika zvigadzirwa zvemhando yenyaya dzakabatana nekupfeka kwembiya:

| Product Quality Issue | Tsanangudzo |

|---|---|

| Kunyanya Kupfeka uye Kubvarura | Zvinokonzera kuderedzwa kwekubuda, kusawirirana kusanganisa, uye kuwedzera mari yekugadzirisa. |

| Melt Fracture | Mhedzisiro munzvimbo yakakasharara kana isina kurongeka, inokanganisa chitarisiko uye michina. |

| Die Build-Up | Inokonzeresa hurombo hwemhando yepamusoro uye kusawirirana kwedimensional nekuda kwekuparara kwepolymer. |

Pandinoona matambudziko aya, ndinoziva kuti yave nguva yekuongorora dhiramu nemascurus.

Kuwedzera Kwekushandisa Kwemagetsi

Ndinonyatsoteerera kune mabhiri angu emagetsi. Kana iyo extruder inoshandisa simba rakawanda kupfuura kare, ndinoziva kushanda kwakadzika. Yakasakara screw zvinhu zvinomanikidza muchina kuti ushande nesimba. Izvi zvinowedzera kushandiswa kwesimba uye mari. Ndinogaroongorora screws nedhiramupandinoona spike mukushandiswa kwesimba. Kutsiva nhengo dzakasakara kunobatsira kudzoreredza kushanda kwakanaka uye kuchengetedza mari.

Kakawanda Kuchengeta uye Kugadzirisa Matambudziko

Kudzokorora Kuvhara kana Jams

Ini ndinowanzo kutarisana nema blockages kana jams mune yangu extruder kana sisitimu isiri kufamba zvakanaka. Zvinhu zvakawanda zvinogona kukonzera matambudziko aya:

- Kudzoreredza zvidhinha zvekukanya dzimwe nguva zvinogadzira nzvimbo dzakanyanya-kudzvanywa, izvo zvinotungamira mukumisikidza uye kuvharika.

- Kunyanya kucheneswa pakati pe screw ne barrel inobvumira zvinhu kuyerera kumashure, zvichikonzera shanduko yevhoriyamu uye jams.

- Akasakara screw ndege kana zvikwambo mukati medhiramu zvinokanganisa kusanganisa maitiro. Izvi zvinokonzera zvidimbu zvisina kunyunguduka uye kusaenzana kwezvinhu zvakakora.

- Kana iyo screw dhizaini isingaenderane neiyo zvinhu zvivakwa, ini ndinoona kamwe-kamwe mutoro unowedzera kana kutomira kwezvinhu, izvo zvinogona kumisa kugadzirwa.

Pandinoona matambudziko aya, ndinozivamidziyo yangu inoda kutarisirwa.

Ruzha rusina kujairika kana mavibrations

Ruzha runoshamisa kana kudedera zvinogara zvichibata pfungwa dzangu panguva yekushanda. Manzwi aya anowanzoratidza matambudziko akadzama. Ndakadzidza kutarisa kune zvinotevera:

| Rudzi rweKukundikana | Chikonzero | Performance |

|---|---|---|

| Bearings dzakuvadzwa | Kushandiswa kwenguva refu, kusazora mafuta zvakanaka, kuwandisa, kana kuisa zvisina kunaka | Kuwedzera vibration uye ruzha, kusagadzikana screw rotation, zvinogoneka screw misalignment |

| Gearbox kukundikana | Kupfeka, kushaikwa kwekuzora, kusvibiswa kwemafuta, kana kuwandisa mutoro | Ruzha rwegiya, tembiricha yemafuta yakakwira, kushanda kwakaderera, njodzi yekuputsika kwegiya |

Dzimwe nguva, ini ndinonzwawo ruzha rusinganzwisisike kubva mukusarongeka, mabhengi akatyoka, kana kunyange zvinhu zvekunze mukati medhiramu. Aya masaini anondiudza kuti ndimire uye ndiongorore Parallel Twin Screw Barrel YeExtruder ipapo.

Higher Frequency of Repairs

Pandinoona ndagadzirisa extruder kakawanda, ndinoziva kuti chimwe chinhu chakaipa.Kugadziriswa kazhinji kunorevasystem iri kupera. Ini ndinoronda kangani ndinotsiva zvikamu kana kugadzirisa jamu. Kana chirongwa chekugadzirisa chikava chipfupi, ndinofunga kutsiva mbiya kana screws. Izvi zvinondibatsira kuti ndidzivise kutadza kukuru uye kuchengetedza mutsara wangu wekugadzira uchifamba zvakanaka.

Material Leakage kana Kusvibiswa muParallel Twin Screw Barrel YeExtruder

Zviratidzo zveLeakage Around Barrel

Pandinomhanyisa extruder yangu, ndinogaratarisa kuti pane kubudakumativi dhiramu. Kudonha kunogona kuratidza matambudziko makuru mukati memuchina. Ndinowanzoona madziva madiki echinhu chakanyungudutswa padyo nechiteshi chemagetsi kana padivi pemadhiramu. Dzimwe nguva, ndinoona kunhuwa kunopisa kana kusvuta, izvo zvinondiudza kuti zvinhu zviri kutiza kwazvisingafanire.

Zvinetso zvinoverengeka zvinogona kukonzera kuvuza uku:

- Material backflow kubva kune isina musoro screw dhizaini

- Chiteshi chepombi chisina kunaka kana dhizaini yekubuda nemhepo inoteya zvinhu zvakanyungudutswa

- Mechanical kupfekaizvo zvinowedzera mukaha pakati pesiruu uye mbiya

- Kudzora tembiricha isina kunaka, iyo inogona kupisa uye kukuvadza chirongo

- Kugadzira abrasive zvinhu kana kumhanyisa muchina kwenguva yakareba, izvo zvinowedzera kupfeka

- Matambudziko ekuzora anosimudza kupokana uye anokonzera kunyanya kupfeka

Kana ndikaona chimwe chezviratidzo izvi, ndoziva yangu Parallel Twin Screw Barrel For Extruder inoda kutarisisa.

Zvinosvibisa muFinal Product

Ndinogara ndichiongorora zvinhu zvangu zvapedza kuona zviratidzo zvekusvibiswa. Kana dhiramu rapera kana kukundikana, ndinowanzoona shanduko mukutaridzika uye kusimba kwechigadzirwa. Tafura iri pazasi inoratidza zvimwematambudziko akajairikauye kuti vanotaridzika sei:

| Nyaya | Mhedzisiro paChigadzirwa Hunhu | Zviratidzo Zvinooneka |

|---|---|---|

| Surface Delamination | Mitsetse isina kusimba, kupeuka, kana kupeuka | Kupepeta kana kupepeta pamusoro |

| Discoloration | Mavara emavara, zvigamba zvisina kujairika, simba rakaderedzwa | Mitsetse kana mavara asina kujairika mavara |

| Splay Marks | Brittle parts, kutadza kukanganiswa kwemaitiro, mavanga epamusoro | Silvery kana makore ane mitsetse |

Pandinoona zvikanganiso izvi, ndinoziva kuti kusvibiswa kana kupfeka mukati medhiramu ndiko kungangove kuri chikonzero. Ndinoita nekukurumidza kudzivirira kukuvadza kwakawanda uye kuchengetedza zvigadzirwa zvangu pachiyero chepamusoro.

Obsolescence uye Kuenderana Matambudziko

Yechinyakare Barrel Dhizaini

Ini kazhinji ndinoona vakura extruders vachinetsekana kuti vaenderane nezvitsva zvekugadzira zvinodiwa. Pandinoshandisa andhizaini yechinyakare, ndinoona kuti haigone kubata zvinhu zvichangoburwa kana kuunza mashandiro akafanana nemidziyo yemazuva ano. Mumakore gumi apfuura, vagadziri vakaita budiriro huru mumapatya maviri screw barrels. Kufambira mberi uku kunondibatsira kugadzirisa mamwe marudzi emapurasitiki uye zvinowedzera. Ini ndinovimba neazvino madhizaini kuti ndiwedzere kuburitsa uye kunatsiridza mhando yechigadzirwa. Heino tafura inoratidza dzimwe shanduko dzakanyanya kukosha:

| Kufambira mberi | Impact paKuita |

|---|---|

| Enhanced material processing range | Kugona kugadzirisa zvakanyanya viscous uye zvakaoma zvinhu |

| Higher output rates | Kuwedzera kwehuwandu hwekugadzira zvichienzaniswa ne-single-screw extruders |

| Kuderedza kupisa kwekupisa | Ipfupi yenguva yekugara inotungamira kune zvirinani zvinhu zvemhando |

| Modular dhizaini | Kuvandudza kusanganisa kushanda zvakanaka uye kushanduka kwekushanda |

Pandinoenzanisa midziyo yangu yekare neaya maficha matsva, ndinoona kutadza kwandinoita nekusavandudza.

Kusapindirana neZvishandiso Zvitsva kana Maitiro

Ini kazhinji ndinoda kushanda nemapolymer matsva kana additives. Dzimwe nguva, yangu yakakura Parallel Twin Screw Barrel YeExtruder haigone kubata idzi shanduko. Ndinoona kusasanganiswa kwakanaka, kunyunguduka kusina kuenzana, kana kunyange majamu emuchina. Madhiramu matsva anoshandisa modular screw zvinhu uye zvirinani kutonga tembiricha. Aya maficha ngaanditendere kuchinja zvinhu kana kuchinja maitiro nekukurumidza. Kana chirongo changu chikatadza kuenderera mberi, ndinoisa panjodzi yekurasikirwa nebhizinesi kana kudonha kumashure kwevanokwikwidza. Ndinogara ndichitarisa kana midziyo yangu ichienderana neyazvino indasitiri inoda ndisati ndatanga chirongwa chitsva.

Kuongorora uye Kuongorora Mazano eParallel Twin Screw Barrel YeExtruder

Routine Visual Checks

Ndinogara ndichitanga zuva rangu nekunyatsofamba ndichitenderedza extruder yangu. Ndinotsvaga makatsemuka mumadhiramu kana matinji mufuremu. Ndinotarisa mabhaudhi akaregedzeka uye ndinoasimbisa ipapo kuti amise mavibrations. Ini ndinoita shuwa kuti lubrication system yazara uye ndinotarisa kunobuda. Ini zvakare ndinoongorora iyo yekutonhodza sisitimu kuti ndione kana iyo inotonhorera nhanho uye kuyerera kwakaringana. Ndinotarisa kubatanidza kwemagetsi ese kuti ndive nechokwadi kuti akachengeteka uye haana kukuvara. Ndinotarisa ma screws kuti ndione kusakara kana tsvina. Mazano ekubhururuka anofanirwa kugara akapinza, uye hapafanirwe kuve nenzvimbo yakawandisa pakati pesiruu nedhiramu. Kana ndikaona makwara kana ngura mukati medhiramu, ndinogadzirisa dambudziko ndisati ndatanga kugadzira.

Zano: Ndinogara ndichitaura cherokubuda mumapombi kana pombinokukurumidza kudzivisa kutambisa zvinhu.

Kuyera Kupfeka uye Kushivirira

Ini ndinoshandisa maturusi chaiwo kuyera dhayamita yedhiramu uye screw-to-barrel clearance. Ndinoenzanisa zviyero zvangu kune zvinokurudzirwa kushivirira. Kana ndikaona dhayamita yedhiramu kana gaka rakura zvakanyanya, ndinoziva kuti inguva yekuronga kugadzirisa kana kutsiviwa. Ini ndinochengeta chinyorwa chezviyero izvi kuti ndigone kuona shanduko nekufamba kwenguva. Izvi zvinondibatsira kubata matambudziko nekukurumidza uye kuchengetedza yanguParallel Twin Screw BarrelYeExtruder inomhanya zvakanaka.

Consulting Manufacturer Guidelines

Ndinogara ndichiverenga bhuku remugadziri ndisati ndaita chero shanduko. Bhuku racho rinondipa kushivirira kwakakodzera, zvirongwa zvekugadzirisa, uye matanho ekuongorora. Ndinotevera zano ravo rekuchenesa, kuzora mafuta, uye kutsiva chikamu. Kana ndine mibvunzo, ndinobata mugadziri kuti anditsigire. Izvi zvinondibatsira kuchengetedza midziyo yangu uye kuchengetedza mutsara wangu wekugadzira wakachengeteka.

Kuita Replacement Sarudzo

Mutengo-Benefit Analysis

Kana ndafunga kutsiva yangu Parallel Twin Screw Barrel YeExtruder, ini ndinogara ndichitanga nekuongororwa kwemari-bhenefit. Ini ndinotarisa kune akati wandei akakosha zvinhu zvinobata pasi pasi. Ndinoda kuve nechokwadi chekuti mari yangu inobhadhara mukufamba kwenguva. Heino tafura inondibatsira kuenzanisa pfungwa huru:

| Factor | Tsanangudzo |

|---|---|

| Kushanda Kwesimba | Kuchengetedzwa kwesimba kunotungamira mukuderedzwa kwemitengo kwenguva refu, kuwedzera kukwikwidza muindasitiri. |

| Equipment Lifespan | Dhizaini yakasimba uye inogara yakasimba inowedzera hupenyu hwemasikiru nemadhiramu, ichideredza mitengo yekutsiva. |

| Maintenance Costs | Kugadzirisa nguva dzose kunogona kuderedza nguva uye kudzivirira kugadziriswa kwechimbichimbi kunodhura, zvichikanganisa mari yose. |

| Quality Consistency | Hunhu hunoenderana hunodzivirira kukanganisa kwechigadzirwa uye nyaya dzekutonga, izvo zvinogona kuunza imwe mari. |

| Kubudirira Kwekushanda | Kuvandudzwa kwekushanda kunoderedza kushandiswa kwesimba uye kunowedzera kubuda, zvichikanganisa purofiti yese. |

Ini ndinoongorora chimwe nechimwe chinhu uye ndinozvibvunza kana bhodhoro razvino richizadzisa zvandinoda. Kana ndikaona mabhiri emagetsi achikwira kana kugadziriswa nguva nenguva, ndinoziva kuti inguva yekuita. Consistent product quality ine basa zvakare. Kana ndikacherechedza kukanganisa, ndinofunga mutengo wekurasikirwa kwekutengesa uye kunyunyuta kwevatengi. Nekuyera mapoinzi aya, ndinoita sarudzo yakangwara yebhizinesi rangu.

Kutsiviwa Kwenguva Kuti Uderedze Nguva Yekuzorora

Ndinogara ndichironga kutsiva kwangu kuchengetedza nguva yekuzorora yakaderera sezvinobvira. Ini ndinoronga basa panguva inononoka yekugadzira kana mahwindo ekugadzirisa. Kunyatsotora nguva kunondibatsira kuti ndidzivise mari yakarasika uye kuti timu yangu irambe ichibudirira. Ini ndinoshandisa tafura kuteedzera zvakanakira kuronga kwakanaka:

| Benefit | Muzana Reduction |

|---|---|

| Waste rates | 12–18% |

| Mari inodhura | 10% |

| Nguva yekuzorora | kusvika ku30% |

Pandinotsiva dhiramu panguva yakakodzera, ndinoona kusarasa kushoma uye mari shoma yesimba. Chikwata changu chinopedza basa nekukurumidza, uye kugadzira kunotanga zvakare nekukurumidza. Ndinogara ndichitaurirana nevashandi vangu uye vatengesi kuti ndive nechokwadi chekuti zvese zvinofamba zvakanaka. Nguva yakanaka inochengetedza purofiti yangu uye inochengeta vatengi vangu vachifara.

Ndinogara ndichitarisa zviratidzo izvi mukati manguparallel twin screw barrelzve extruder:

- Ini ndinotarisisa kupera kwekupfeka; kugadzirisa kushanda kusvika0.3mm, asi ndinotsiva dhiramu kana gap richikura kana kuti nitriding layer ikakundikana.

- Ini ndinoyera mari dzekugadzirisa nekutsiviwa uye kupfeka kwe track kudzivirira kudzika.

- Ndinoongorora midziyo yangu nguva dzose500–1,000 maawa.

- Macheki enguva nenguva anondibatsira kubata matambudziko nekukasira.

Kugara ndichitarisisa kunoita kuti kugadzirwa kwangu kuve kwakanaka uye kunochengetedza mari.

FAQ

Kangani kandinofanira kuongorora yangu parallel twin screw barrel pakupfekwa?

Ndinotarisa bhodhoro rangu ega ega 500 kusvika 1,000 maawa ekushanda. Kugara ndichiongorora kunondibatsira kubata matambudziko nekukurumidza uye kuchengetedza extruder yangu ichimhanya zvakanaka.

Zano: Ndinogara ndichinyora mibairo yekuongorora kuitira ramangwana.

Chii chinonzi screw-to-barrel clearance isati yatsiviwa?

Ini ndinotsiva dhiramu apo gap-ku-barrel rinopfuura 0.3 mm. Izvi zvinodzivirira kudonha uye kuchengetedza chigadzirwa chemhando yepamusoro.

| Chikamu | Max Clearance (mm) |

|---|---|

| Chikuro-ku-Bharel | 0.3 |

Ndinogona kugadzirisa dhiramu rakasakara pane kuritsiva here?

Ini ndinogadzirisa diki kupfeka kusvika 0.3 mm. Kana iyo nitriding layer ikatadza kana kukuvara kwakanyanya, ini ndinosarudza kutsiva kuita zvirinani.

Nguva yekutumira: Aug-28-2025