Kuchengetedza kushanda zvakanaka mumapatya-screw extruders kwakakosha pakugadzirwa kwakakwana. Nguva yekuzorora uye kupfeka zvinogona kuwedzera zvakanyanya mari uye kukanganisa mafambiro ebasa. Kushandisa nzira dzakapupurirwa kunowedzera kushanda uye kunoderedza zvipingamupinyi zvekushanda. Vagadziri vanofanira kukoshesa mazano anotarisa kune akasimba maviri-screw extruder mbiya, mapatya parallel screw barrels, uye.conical twin screw extruder barrels, pamwe chete neyakagadziridzwa kugadzirisa mamiriro epurasitiki extruder single screw barrels.

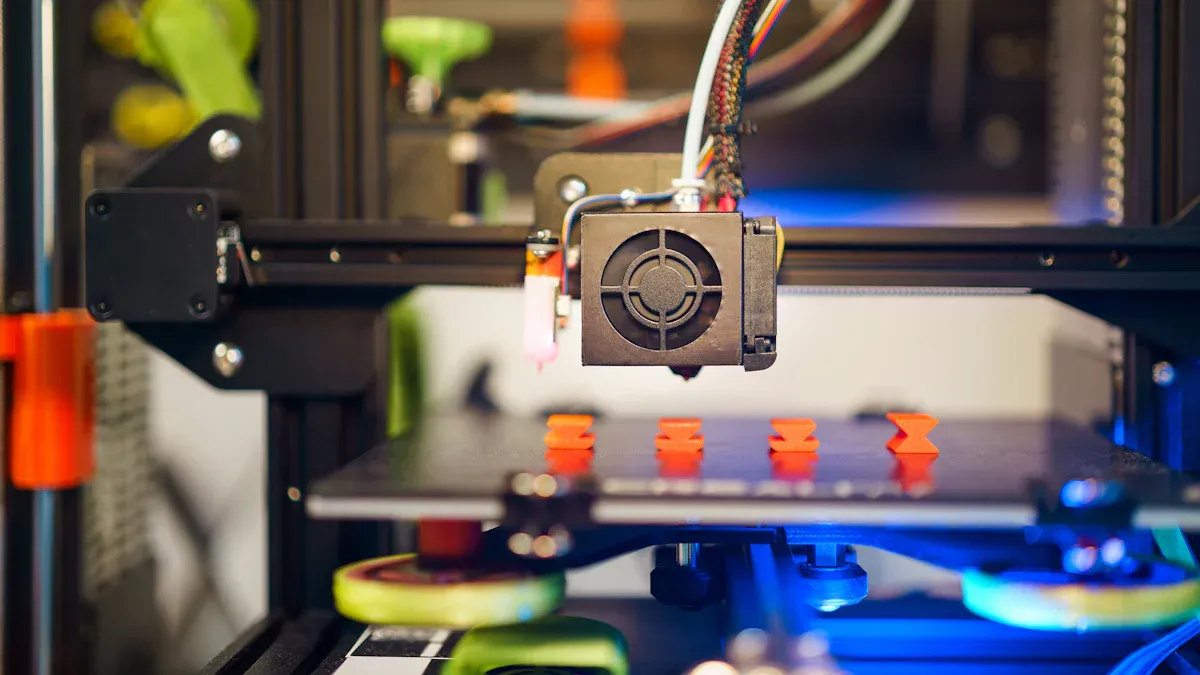

Zvinokonzera Kupfeka muDurable Twin-Screw Extruder Barrels

Kuumbwa Kwezvinhu

Kuumbwa kwezvinhu zvemapatya-screw extruder barrels kunoita basa rakakosha mukusimba kwavo uye kuita kwavo. Kusarudza zvinhu zvakakodzera zvinogona kuderedza zvakanyanya kupfeka uye kuwedzera hupenyu hwezvikamu izvi. Zvikonzero zvinowanzoitika zvekupfeka zvine chekuita nekuumbwa kwezvinhu zvinosanganisira:

| Chikonzero Chekupfeka | Tsanangudzo |

|---|---|

| Kusarudzwa kwezvinhu zvisina kunaka | Kusakwana simba rekushanda kwescrew uye mbiya kunoderedza hupenyu hwavo. |

| Kusakwana kupisa kurapwa kuoma | Kuomeswa kwakaderera kunowedzera kupfekedzwa panzvimbo dzekushanda. |

| Low machining kururama | Kusarurama kwakashata uye kuiswa kunogona kutungamirira kune kukakavara uye kukurumidza kupfeka. |

| Kuvapo kwemafillers mune extruded material | Mafirita senge calcium carbonate kana girazi fiber anowedzera kupfeka. |

Alloying zvinhu mudhiramu zvinhu zvakare zvinopesvedzera kuramba abrasion uye corrosion. Semuyenzaniso, Ni60 inoratidza inokatyamadza kuramba ichipokana nekupfeka abrasive, ichidzikisa mareti ekupfeka uye mitengo yekushanda. Iyi alloy inochengetedza kutendeseka kwemuchina pane tembiricha dzakakwirira, kuve nechokwadi kugadzikana kwemaitiro.

Processing Conditions

Processing mamirirozvinokanganisa zvakanyanya kupfekwa kweakasimba mapatya-screw extruder barrels. Zvinhu zvakadai setembiricha, kudzvanywa, uye hunhu hwezvinhu zviri kugadziriswa zvinogona kukurumidza kupfeka. Mamiriro ekugadzirisa akakosha anobatsira pakupfeka anosanganisira:

| Factor | Tsanangudzo |

|---|---|

| Abrasive Materials | Kugadzira makomisheni akazadzwa zvakanyanya, senge mapurasitiki akazadzwa negirazi kana mamineral powders, anogona kukurumidzira kusakara pane ese screws nemadhiramu. |

| High Temperature uye Pressure | Kugara kwenguva refu kune tembiricha yakanyanyisa kana kudzvanyirira kwakanyanya kunogona kunetesa dhiramu repamusoro, zvichiita kuti ikukurwe. |

| Chemical Attack | Mamwe mapolymer kana ekuwedzera anogona kuita kemikari nedhiramu zvinhu, zvichikonzera ngura kana gomba nekufamba kwenguva. |

| Maintenance Yakashata | Kuongororwa kusingawanzo uye kunonoka kugadzirisa kunobvumira kupfeka kudiki kushanduka kuita kukuvara kukuru. |

Tembiricha uye kusimba kwekuchinja panguva yekushanda kunogona zvakare kukanganisa zvakanyanya hupenyu hwemapatya-screw extruder barrels. Tembiricha dzepamusoro dzekushanda, kazhinji dziri pamusoro pe200 ° C, dzakasanganiswa nekudzvanywa kwakanyanya, dzinobatsira pakupfeka nekuora kwedhiramu uye screw. Iyo abrasive mhedzisiro yekunyunguduka uye kushushikana kwemagetsi panguva yekushanda kunowedzera nyaya idzi, zvichikonzera kurasikirwa kwezvinhu uye kutadza kupedzisa.

Mechanical Stress Factors

Mechanical stress factor ndechimwe chinhu chakakosha chinokonzera kutadza kukasika mumapatya-screw extruder barrels. Izvi zvinoshungurudza zvinogona kubuda kubva kune akasiyana siyana ekushanda mamiriro, kusanganisira:

- Abrasive kupfeka kunokonzerwa neakaomarara particles mupolymer eroding screw uye mbiya pamusoro.

- Kupfeka kwekushisa kunokonzerwa nekupisa kwakanyanya uye kupisa kusina kuenzana kwecylinder.

- Kuneta kupera kunokonzerwa nekudzokororwa kushushikana uye kutenderera, kunetesa screw zvinhu nekufamba kwenguva.

Cyclic loading inogonawo kukonzera kuneta uye kupfeka mumapatya-screw extruder barrel components.Torsional uye kukotama kushushikanainogona kutanga uye kuparadzira kutsemuka, nepo coarse carbide deposits ichitungamira kune micro-cracks pamusoro peiyo shaft. Kukanganisa kwakadai semaburi uye sediments kunobatsira kukurumidza kukura nekukundikana.

Kunzwisisa izvi zvinokonzeresa kupfeka mune yakasimba mapatya-screw extruder barrels inobvumira vagadziri kuti vashandise nzira dzinoshanda dzekugadzirisa uye optimization, pakupedzisira inosimudzira kugadzirwa.

Zviratidzo Zvekupfeka Kutarisisa muTwin-Screw Extruder Barrels

Performance Degradation

Vashandi vanofanira kunyatsotarisa kuparara kwekuita mumapatya-screw extruder. Zviratidzo zvekutanga zvinosanganisira:

- Kuwedzerwa kwemvumo yekubhururuka nekuda kwekupfeka pamazano ekubhururuka.

- Iko kudikanwa kwekuwedzera screw speed kuchengetedza inogara iri throughput rate.

- Tembiricha yekuyerera kwepamusoro inokonzerwa nekudzikira kwekupisa-kutamisa coefficient.

Kukanganisa kwekuita kunogona kukanganisa zvakanyanya kunaka kwechigadzirwa. Semuenzaniso, kusiyana kwekushisa kunogona kudzivirira kuparara kwezvinhu zvinopisa zvinopisa, kuve nechokwadi chekunyunguduka kwakafanana. Hukama huri pakati pekumhanyisa screw uye torque inokanganisawo shear inoshandiswa panguva yekugadziriswa. Kumhanya kwepamusoro kunogona kuvandudza kusanganisa asi kunogona kutungamira mukupisa.

| Factor | Impact paChigadzirwa Hunhu |

|---|---|

| Tembiricha | Inodzivirira kuderedzwa kwezvinhu zvinopisa zvinopisa uye inovimbisa kunyunguduka kwakafanana. |

| Screw Speed uye Torque | Inokanganisa shear yakaiswa; kumhanya kwepamusoro kunovandudza kusanganisa asi kunogona kukonzera kupisa. |

| Kubudirira Degassing | Inobvisa magasi akavharirwa, kudzivirira kukanganisa uye kuve nechokwadi chekuenderana uye kusimba kwezvinhu. |

Visual Inspection Indicators

Kuongorora kwekuona kwakakosha pakuona kupfeka mumapatya-screw extruder barrels. Vashandi vanofanira kutsvaga:

- Surface Delamination: Matunhu asina kusimba anogona kuoneka seanopepereruka kana kupeuka.

- Discoloration: Mavara emavara kana zvigamba zvisina kujairika zvinogona kuratidza kuderedzwa kwesimba.

- Splay Marks: Sirivha kana makore ane mitsetse inoratidza brittle zvikamu uye kushomeka kwekudzivirira.

Kuongorora zviratidzo zvakajeka zvekukuvara kwepasi, senge yakadzika grooves pane screw element, kwakakosha. Vafambisi vanofanirawo kutarisa kukuvara kwakanyanya kwemuchanicha mukati medhiramu uye kuongorora pakatsemuka pane screw shaft tip.

Kuyera Kushivirira

Kuyera nguva dzose kunobatsira kuongorora mamiriro emapatya-screw extruder barrels. Maitiro anokurudzirwa anosanganisira:

- Kuchenesa kwakadzika dhiramu reextruder rine zvinhu zvekuchenesa.

- Kushandisa dial bore gauge uye micrometer kutora zviyero zviviri kusvika pamainji matatu pasi pebhororo.

- Kuongorora nzvimbo yegomba rekudya kune makatsemuka, washout mavara, mabhendi, uye zvimwe zvikanganiso.

Vashandi vanofanira kuyera hurefu hwose vachishandisa tepi chiyero kubva kumucheto kusvika kumagumo emhino. Vanofanirawo kuyera shank kureba uye kubereka kureba. Kushandisa maturusi senge dial calipers uye micrometers kunovimbisa kwakaringana kuongororwa kwekupfeka.

- Tape Kuyera

- Seti yeCalipers

- Dial Caliper

- 0-7 ″ maMikiromita

- .500″ gobvu parallel bar

- 25′ Tepi Kuyera

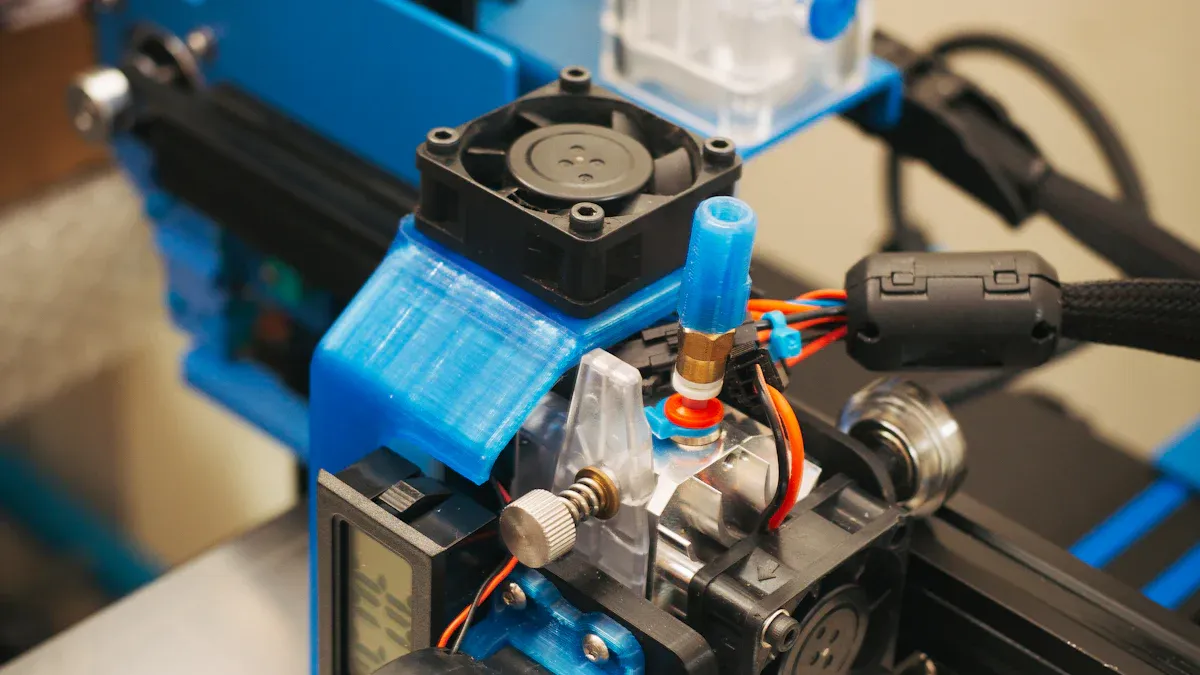

Inoshanda Mhinduro dzekudzikisa Downtime muTwin-Screw Extruder Barrels

Kuti uwedzere kushanda kwetwin-screw extruder, vagadziri vanofanirwa kushandisa mhinduro dzinoita kudzikisira nguva. Mhinduro idzi dzinosanganisira nzira dzekusarudza zvinhu, yakagadziridzwa mamiriro ekugadzirisa, uye maitiro ekudzivirira ekuchengetedza.

Material Selection Strategies

Kusarudza zvinhu zvakakodzerakune mapatya-screw extruder barrels yakakosha pakurarama kwenguva refu uye kuita. Tafura inotevera inoratidzira mhando dzakasiyana dzezvinhu uye mabhenefiti azvo akakosha:

| Material Type | Key Benefits |

|---|---|

| Carbon steel | Basic durability |

| Simbi isina ngura | Good corrosion resistance |

| Alloy simbi | Enhanced mechanical properties |

| Upfu metallurgy simbi | Superior kupfeka uye corrosion kuramba, yakatsetseka zviyo chimiro, yakakwira mechanic simba, hupenyu hurefu hwesevhisi |

Kushandisa machira epamusoro kana kurapwa kwepamusoro kunogona kuwedzera kuvandudza kupfeka kuramba. Semuyenzaniso, marapirwo e nitriding anogona kuwedzera hupenyu hwesevhisi hwema screws kaviri kusvika katatu. Pamusoro pezvo, chromium uye molybdenum plating inosimudzira kuomarara uye kupfeka kuramba, zvakanyanya kunatsiridza mashandiro ebhari.

Optimized Processing Conditions

Kugadzira nzvimbo dzekushanda dzakakodzera kwakakosha pakuchengetedza kuenderana kwekugadzirisa zvinhu. Kuita chiyero chekushanda maitiro kunogona kudzora maitiro paramita zvinobudirira. Aya anotevera mhinduro anogona kukwenenzvera kugadzirisa mamiriro:

- Kudzora Tembiricha uye Kumanikidza: Chengetedza tembiricha yakagadzikana uye kumanikidza kudzivirira kupfeka kwemafuta uye kuve nechokwadi chekuyerera kwezvinhu.

- Monitor Material Maumbirwo: Gara uchitarisa kuumbwa kwezvinhu zviri kugadziriswa kudzivirira kupfeka abrasive kubva kune fillers.

- Rongedza Kukurumidzira: Optimize screw speed kuenzanisa kusanganisa kusanganisa uye chizvarwa chekupisa, kudzivirira kupisa.

Nekutora maitiro aya, vagadziri vanogona kuderedza zvakanyanya kupfeka pamapatya-screw extruder madhiramu uye kuwedzera hunyanzvi hwekugadzira.

Dziviriro Yekuchengetedza

Urongwa hwekugadzirisa hwakasimba hwakakosha pakudzikisa nguva isina kurongeka. Tafura inotevera inosimbisamaitiro ekudzivirira anobudirira ekuchengetedza:

| Dzidzira | Tsanangudzo |

|---|---|

| Routine Maintenance Schedules | Kugara uchichengeta kunoita kuti michina ifambe zvakanaka uye kudzivirira kuputsika kusingatarisirwe. |

| Operator Training | Vashandi vakadzidza vanogona kuona zviratidzo zvekutanga zvekupfeka uye kugadzirisa zvidiki zvisati zvawedzera. |

| Spare Parts Inventory | Kuchengeta heta yezvikamu zvakakosha kunovimbisa kugadzirisa nekukurumidza uye kunoderedza nguva yekudzikira. |

| Zvinhu Zvepamusoro-soro | Zvikamu zvinogadzirwa kubva kuzvinhu zvinogara kwenguva refu zvinosimudzira mashandiro uye kuderedza zvinodiwa zvekugadzirisa. |

| Kuzora kwakakodzera | Mafuta emhando yepamusoro anoderedza kupokana, anowedzera hupenyu hwezvikamu, uye anonatsiridza kushanda zvakanaka. |

| Kuongorora Nguva Dzose | Kutarisa kusakara uye kubvaruka kunogona kudzivirira kugadzirisa kunodhura uye kuderera, kuchengetedza kuenderana kwechigadzirwa mhando. |

Macheki ekugadzirisa anofanirwa kuitika nguva nenguva kuti akwidze hupenyu hwekushanda hwemapatya-screw extruder barrels. Semuenzaniso, kushandura oiri nemafuta ekuzora maawa ega ega e4000 uye kuongorora kupfeka kwekota kunogona kudzivirira nyaya dzakakosha.

Nekuita izvi zvigadziriso zvinobudirira, vagadziri vanogona kuderedza zvakanyanya nguva yekudzikira uye kusimudzira kugona kwemapatya-screw extruder mashandiro avo.

Vagadziri vanogona kuderedza zvakanyanya nguva yekudzikira uye kupfeka nekushandisa nzira dzinoshanda dzekugadzirisa. Kuongororwa nguva dzose, cheki yekuzora, uye kugadzirisa panguva yakakodzera kunovimbisa kuita kwakakwana.Kugadzira kudyidzana kwakasimba kwevanopainokwidziridza kuwanikwa kwezvikamu zvemhando yepamusoro uye rutsigiro rwenyanzvi. Kudyidzana uku kunosimudzira zvigadziriso zvakagadziridzwa zvinoenderana nezvinodiwa zvekushanda, pakupedzisira kutyaira kubereka uye kugona.

Mazano Anokosha Ekuchengetedza:

- Kuongororwa kwezuva nezuva uye cheki yekuzora

- Monthly screw and barrel inspections

- Gore rega rega rekugadzirisa hurongwa

Nekuisa pamberi maitiro aya, vagadziri vanogona kuwana inogara kwenguva refu yekushanda kubudirira.

FAQ

Chii chinonyanya kukonzera kupfeka mumapatya-screw extruder barrels?

Chikonzero chikuru chekupfeka chinobva pakuumbwa kwezvinhu, mamiriro ekugadzirisa, uye mechanical stress zvinhu panguva yekushanda.

Kangani pandinofanira kuongorora mapatya-screw extruder mbiya?

Ongorora mapatya-screw extruder barrels nguva nenguva, zvakanaka mwedzi wega wega, kuti uone kupera uye kudzivirira kugadzirisa kunodhura.

Ndezvipi zvinhu zvakanakira mapatya-screw extruder barrels?

Alloy simbi uye poda metallurgy simbi inopa yepamusoro kupfeka kuramba uye kusimba, inosimudzira hupenyu hwemapatya-screw extruder mbiya.

Nguva yekutumira: Sep-05-2025