Ndiri kuona seiSingle Screw Barrelsshandura kushandiswa kwepurasitiki. Pandinoshandisa Single screw barrel yekudzokorodza granulation, ini ndinoona zvirinani kunyunguduka, kusanganisa kwakadzikama, uye kushoma kupfeka. ZvanguPlastic Extruder YePlastiki Recyclinginofamba zvakanaka. Netembiricha chaiyo uye screw speed, zvanguExtruder For Plastic Recyclinginowana kuburitsa kwepamusoro uye mhando yepellet.

- Kunyunguduka flux

- Screw speed

- Kupisa kwebhare

- Shear stress management

Makiyi Mechanism Kutyaira Kubudirira

Yakavandudzwa Melt Homogenization

Pandinoshandisa recycling yangu extruder, ndinotarisa pakuwana yunifomu inonyungudika. Melt homogenization inoreva kusanganisa purasitiki zvakakwana sezvainonyunguduka, saka pellet yega yega ine hunhu hwakafanana. Ndakadzidza izvozvokudzora tembiricha yekunyungudika uye kuyererakwakakosha. Zvidzidzo pamapurasitiki akaita senaironi nepolypropylene zvinoratidza kuti kana ndikachengeta yunifomu yakanyunguduka, ndinowana mapellets ari nani anogadzirwazve. Kana iyo yakanyunguduka isingaenderane, ipurasitiki yakadzokororwa inogona kupera simba kana brittle.

Ini ndinoona mutsauko wemhando yepellet pandinoshandisa imwe screw barrel yakagadzirirwa kusanganisa zvirinani. Semuyenzaniso, tsvakiridzo yemelt-state shear homogenization inoratidza kuti high-shear kusanganiswa mumabharari escrew inovandudza kuwirirana kwemuviri uye nekupisa kwemapurasitiki akadzokororwa. Iyi nzira inoderedza zvinosvibisa uye inoshandura chimiro chepolymer nenzira inobatsira nemamwe matanho ekudzokorodza. Ini ndinoona kuti mapellets angu akadzokororwa ane hurema hushoma uye kuita zvirinani kana kunyungudika kwaita homogeneous.

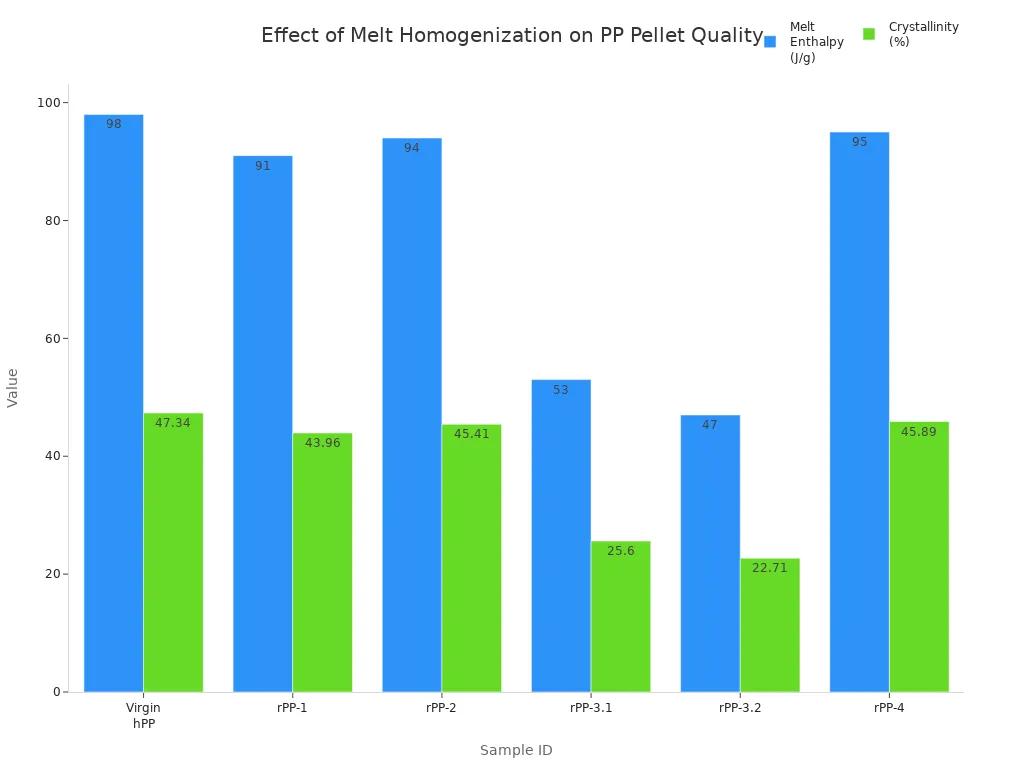

Nhamba dzinotsigira zvandinoona muchitoro changu. Kana ini ndichienzanisa recycled polypropylene samples, avo vane yakakwirira crystallinity uye inonyungudutsa enthalpy inotaridzika uye inoita zvakanyanya senge virgin plastic. Heino tafura inoratidza maitiro akasiyana ekugadzirisa mamiriro anokanganisa pellet mhando:

| Muenzaniso ID | Melt Enthalpy (J/g) | Crystallinity (%) |

|---|---|---|

| Mhandara homopolymer PP (hPP) | 98 | 47.34 |

| Yakagadzirwazve PP-1 (rPP-1) | 91 | 43.96 |

| Yakagadzirwazve PP-2 (rPP-2) | 94 | 45.41 |

| Yakagadzirwazve PP-3.1 (rPP-3.1) | 53 | 25.60 |

| Yakagadzirwazve PP-3.2 (rPP-3.2) | 47 | 22.71 |

| Yakagadzirwazve PP-4 (rPP-4) | 95 | 45.89 |

Ini ndinogara ndichivavarira mhinduro senge rPP-1, rPP-2, uye rPP-4, iri padyo nemhandara PP. Yakaderera tsika, senge rPP-3.1 uye rPP-3.2, ndiudze kuti kunyungudika hakuna kusanganiswa zvakanaka kana kuve nekusvibiswa.

Kana ini ndichidzora kunyungudika kuyerera uye kusanganisa, ini zvakare ndinoona zvirinani zvemakanika zvivakwa muchigadzirwa chekupedzisira. Mapellets angu akadzokororwa anotambanudza uye anosimudza anenge pamwe chete nepurasitiki nyowani, zvinoreva kuti ndinogona kuishandisa mukushandisa zvakanyanya kudiwa.

Optimized Screw Geometry

Chimiro uye dhizaini ye screw mukati me extruder yangu inoita mutsauko mukuru. Ndakaedza akasiyana screw geometries uye ndakaona mabatiro aanoita mashandisiro esimba, kunyungudika mhando, uye kubuda. Pandinoshandisa screw ine iyo chaiyo geometry, ini ndinowana zvakanyanya kuenderana musanganiswa uye nepamusoro pekupinda. Iniwo ndinoshandisa simba shoma, iro rinochengetedza mari uye rinoderedza kusakara pamidziyo yangu.

- Screw geometry inokanganisa kuwanda kwesimba randinoda uye kuti tembiricha yekunyunguduka inogara yakatsiga sei.

- Kuwedzera screw kumhanya kunogona kudzikisa simba rekushandisa, asi screw dhizaini inofanirwa kuenderana nezvinhu.

- Barrier screws uye kusanganisa zvinhu zvinobatsira kuchengetedza tembiricha yekunyunguduka uye kunatsiridza musanganiswa.

- Mamwe magadzirirwo escrew rega ndimhanye iyo extruder nekukurumidza pasina kurasikirwa nemhando.

- Iyo yekurudyi screw geometry inoyera kushanda kwesimba nekubuda kwepamusoro uye kunaka kunyungudika.

Ndakaona izvo zvivhariso screws, izvo zvinoparadzanisa mapurasitiki akasimba uye akanyungudutswa, anonditendera kuti ndimhanye nekumhanya kwakanyanya uye kuwana zvimwe zvinobuda. Nekudaro, ini ndinofanira kutarisa kubuda kuti ndichengetedze yunifomu yakanyungudika. Kusanganisa zvinhu senge Maddock shear chikamu chinondipa zvirinani homogenization, zvinoreva kushoma hurema mumapellets angu.

Heino kukurumidza kuenzanisa kwe screw type nemhedzisiro yavo:

| Screw Geometry | Kusanganisa Kuenderana (Homogeneity) | throughput | Notes |

|---|---|---|---|

| Barrier Screws | Yakanaka pane yakakwirira throughput, inoda kungwarira kutonga | High | Yakanakira mabhechi makuru, tarisa kusaenzana kusanganisa nekumhanya kwakanyanya |

| Zvikamu Zvitatu | Yakagadzikana, asi yakaderera throughput | Pakati nepakati | Yakanakira kugadzirwa kwakadzikama, kushoma kuchinjika |

| Mixing Elements | Yakanakisa homogenization | Inosiyana | Maddock shear inopa kusanganisa kwakanyanya, kunyanya kumapurasitiki akaoma |

Ini ndinogara ndichisarudza screw geometry inoenderana nepurasitiki yandiri kudzokorora. Nenzira iyi, ndinowana chiyero chepamusoro chekumhanya, mhando, uye kushandisa simba.

Advanced Barrel Materials

Izvo zvinhu zve screw barrel zvine basa zvakangofanana nekugadzirwa kwayo. Ini ndinovimba nemadhiramu akagadzirwa kubva emhando yepamusoro alloy simbi se38CrMoAl, iyo inopa simba uye kuoma. Pandinoshandisa madhiramu ane nitrided nzvimbo, ndinoona kusvetuka kukuru mukuoma. Izvi zvinoreva kuti midziyo yangu inogara kwenguva refu, kunyangwe pandinogadzira mapurasitiki ane abrasive kana akasvibiswa.

- Alloy masimbi akadai se38CrMoAlA uye AISI 4140 anondipa kusimba kwandinoda.

- Powder metallurgy steels inopa zvakatonaka kupfeka uye kuomesa ngura.

- Nitriding marapirwo anowedzera kuoma kwepasi, kazhinji kusvika paHV900 kana kupfuura.

- Bimetallic coatings, senge tungsten carbide, chengetedza kubva kune abrasive fillers.

- Chromium plating inowedzera imwe nhanho yekudzivirira kubva ngura uye kupfeka.

Ndakaona kuti pandinoshandisa madhiramu ane aya emhando yepamusoro uye machira, ndinopedza nguva shoma nemari pakugadzirisa. Yangu extruder inomhanya kwenguva refu pakati penguva dzesevhisi, uye ini handifanirwe kunetseka zvakanyanya nezvekuputsika. Kuvimbika uku kunondiita kuti nditarise kugadzira emhando yepamusoro akadzokororwa pellets.

Zano:Nguva dzose enderana nebarrel materialkune marudzi emapurasitiki uye zvinowedzera zvaunogadzira. Zvishandiso zvakaoma uye machira anobhadhara kana iwe uchibata abrasive kana yakasanganiswa tsvina yepurasitiki.

Nekubatanidza yakagadziridzwa melt homogenization, optimized screw geometry, uye advanced barrel zvinhu, ndinowana hunyanzvi hwepamusoro uye mhedzisiro iri nani mukushanda kwangu kwepurasitiki. Matanho aya anoshanda pamwechete kuendesa mhando inowirirana, kubuda kwepamusoro, uye kuderera kwemitengo.

Kugadzirisa Zvakajairwa Kudzokorodza Zvinetso

Kugadzirisa Kusvibiswa uye Variable Feedstock

Pandinoita basa rangu rekudzokorodza, ndinotarisana neredhiyo isingafungidzike mazuva ese. Mamwe mabhechi ane epurasitiki yakachena, yakafanana. Vamwe vanosvika vakasanganiswa netsvina, simbi, kana mwando. Ndinoziva kuti zvimedu zveregrind zvisina kuumbwa zvine huzhinji hwakadzikira pane virgin pellets. Izvi zvinoderedza kubuda uye zvinoita kuti extruder yangu ishande nesimba. Kana ndikasagadzirisa nyaya idzi, ndinoona tembiricha yakakwira yekunyungudika uye yakaderedzwa pellet mhando.

Ini ndinovimba neangu screw barrel kubata aya matambudziko. Iyo yakagadziridzwa feed zone geometry, kunyanya yakakurisa homwe yekudya, inovandudza kudya uye solids kutakura. Iyi dhizaini inodzivirira kusamira kwezvinhu uye inochengeta kuyerera kwakadzikama. Ini ndinocherechedza kuti extruder yangu inochengetedza mhando yakanyunguduka kunyangwe pandinogadzira mapurasitiki akasanganiswa kana akasvibiswa.

Heano matambudziko makuru andinosangana nawo mukudzoreredza epurasitiki:

- Irregular regrind shapes uye low bulk density

- Yakaderedzwa kuburikidza nekubudirira

- Higher melt tembiricha uye nhete kugadzirisa mahwindo

- Kusvibiswa uye kuparara kwezvinhu

- Kugadzirisa kusiyanisa nemapurasitiki akavhenganiswa

My single screw barrel inondibatsira kukunda matambudziko aya. Ini ndinoona zvirinani kudyisa kunyatsoshanda, kuenderana kuyerera kwezvinhu, uye kuderera kwesimba rekushandisa. Iyi tekinoroji inondibvumira kugadzirisa huwandu hwakakura hwemapurasitiki akadzokororwa pasina kupira mhando.

Ini ndinowanzo enzanisa single screw extruder kune mapatya screw extruder. Twin screw machines inopa yakanakisa kusanganisa uye degassing, asi inonetsekana nekumanikidza kwakanyanya uye kusvibiswa. Single screw extruder, seyangu, inobata kusefa-yakanyanya kudzokorodza uye kushivirira zvinosvibisa zviri nani. Heino kuenzanisa nekukurumidza:

| Feature | Single Screw Extruder | Twin Screw Extruder |

|---|---|---|

| Kusanganisa Kubudirira | Kusanganisa kuri pakati nepakati, kushoma homogenization | Kusanganisa kwakanakisa, kwakasimba kugovera / kuparadzira chiito |

| Tembiricha Uniformity | Zvine mwero, zvinogara zvichipisa/kutonhora | Yakanyanya yunifomu kunyunguduka tembiricha kugovera |

| Output Stability | Zvakanaka, zvinogona kuita pulsation | Inopindirana, yakagadzikana kubuda |

| Material Versatility | Yakanakisa kune homogeneous, mhandara zvinhu | Inobata zvinowedzera, zvinosanganiswa, zvakasvibiswa feedstocks |

| Degassing Kugona | Yakaganhurirwa kana kuti hapana | Yakakwirira, ine vacuum ports uye nzvimbo dzekupinda |

| Ideal Use Case | Diki chiyero, yakachena mhandara ABS | Industrial scale, specialty, colored, recycled ABS |

Ini ndinosarudza single screw barrels kune yavo yakakwirira-kudzvanywa kugona uye nani kushivirira kwezvinosvibisa. Sarudzo iyi inondibatsira kuti ndidzivise kugadzirisa zvinodhura uye kuchengetedza tambo yangu yekudzokorodza ichishanda zvakanaka.

Kuderedza Kupfeka kubva kuAbrasive Materials

Mapurasitiki ane abrasive nemafillers, akadai segirazi fibers, talc, uye calcium carbonate, zvinopa dambudziko guru muchirimwa changu. Izvi zvinhu zvinopfeka pasi screws nemadhiramu nekukurumidza. Ndaiwanzotsiva zvikamu kazhinji, izvo zvakawedzera downtime uye mari.

Ikozvino, ini ndinoshandisa single screw barrels ine epamberi ekurapa epamusoro uye machira. Chirongo changu chine nitrided pamusoro uye bimetallic alloy layers. Izvi zvinowedzera kuwedzera kuoma uye kuramba abrasion. Ndinoona musiyano mukuru mukusimba. Midziyo yangu inogara kwenguva refu, kunyangwe pandinoita mapurasitiki akaoma, anopwanya.

Makiyi ekugadzira maficha anondibatsira kuderedza kupfeka anosanganisira:

- Yakagadziridzwa screw geometry kudzivirira kumanikidza spikes uye kunyungudutsa mhirizhonga

- Kusarudzwa kwezvinhu zvinodzivirira kupfeka uye machira ane hunyanzvi

- Yakagadzirirwa dhizaini kune chaiyo mbishi zvinhu uye mafirita

- Precise machining for smooth surface finish

- Simulation software kuti unzwisise kunyungudutsa kudzvanywa kugovera

Ndakadzidza kutiKupfeka kwepamusoro kunoitika pedyo nechikamu chekuchinja, uko kuoma kwesimbi uye kumanikidzwa kunokwira. Nekusarudza zvinhu zvakakodzera uye machira, Ikuderedza kupera kusvika 60%. Kugara uchiongorora uye kuchengetedzwa kwenzvimbo dzepamusoro-soro, senge nzvimbo dzekudyisa uye dzekuburitsa, chengetedza extruder yangu muchimiro chepamusoro.

Zano:Ini ndinogara ndichifananidza dhizaini yangu ye screw barrel kune mapurasitiki uye mafirita andinoita. Iyi nzira inowedzera hupenyu hwemidziyo uye inovandudza kugadzirwa kwakanaka.

Kuvandudza Kugadzikana Kwemaitiro uye Kuenderana Kwekubuda

Kugadziriswa kwakadzikama kwakakosha pakugadzira emhando yepamusoro akadzokororwa pellets. Ndisati ndatora tekinoroji imwechete screw barrel, ndakanetseka nekuyerera, kunyungudika kusagadzikana, uye kushata kwakasimba kuburitsa. Matambudziko aya akakonzera kudzikira kwemitengo yekugadzira, kuwedzera zvisaririra, uye kukwira kwemitengo yevashandi.

Neyangu JT single screw barrel, ini ndinowana yakagadzikana kunyungudika kuyerera uye kunoenderana kubuda. Masisitimu epamberi ekudzora, anosanganisira masensa uye logic controller, anondibatsira kuchengetedza tembiricha yakatsiga uye kudzvanywa. Ini ndinotarisisa mamiriro ekuita kuti ndidzivise kuchinjika kunogona kukanganisa kuvhiya.

Ndinoshandisabimetallic alloys uye machira epamusorokuwedzera kusakara uye kusagadzikana kwemarara. Aya maficha akakosha pakugadzirisa abrasive kana kudzokororwa mapurasitiki. Mamiriro ekugadzirisa akagadzikana anodzivirira kusiyana kwezvinhu zvechigadzirwa uye kuderedza marara.

Heano nhanho dzandinotora kuchengetedza kugadzikana kwemaitiro:

- Kugara uchigadzirisa uye kutsiva panguva yakasakara screws nemadhiramu

- Monitoring tembiricha uye kumanikidzwa ane advanced control systems

- Kushandisa tsika screw profiles kuti zvirinani kunyungudutsa homogeneity uye kusanganisa

- Kuongorora nzvimbo dzepamusoro-soro kuderedza nguva isingatarisirwi

Zvidzidzo zvinoratidza kuti optimize screw kumhanya uye tembiricha nzvimbo inowedzera throughput uye inovandudza kudzokorora. Lower screw kumhanya kunowedzera torque uye kuderedza magetsi emagetsi, zvichitungamira kune zvirinani kushanda uye zvakanyanya kuenderana kubuda. Ndakanyora kuwedzera kwehuwandu hwe18% kusvika 36% mushure mekugadzirisa dhizaini yangu yescrew barrel.

Cherechedza:Kuongorora kunoenderana uye kufembera kugadzirisa kunowedzera hupenyu hwemidziyo uye kunatsiridza kugadzikana kwese kwemaitiro mukushanda kwangu kwekudzokorora.

Nekugadzirisa kusvibiswa, kupfeka, uye kugadzikana kwemaitiro, chirongo changu chimwe chete chinondibatsira kuburitsa mapellets akavimbika, emhando yepamusoro. Ndinosangana nezvinodiwa zvemazuva ano ekudzokorodza nekuvimba uye nekubudirira.

Single Screw Barrel ye Recycling Granulation: Chaiyo-World Results

Kuwedzera Kupfuura uye Hunhu

Pandakachinjira kune imwe screw barrel yekudzokorodza granulation, ndakaona kuwedzera kwakajeka mune zvese throughput uye pellet mhando. Mapellets angu akadzokororwa ava kuratidza simba remuchina riri nani uye kujeka kwakavandudzwa. Ini ndinogona kudzora saizi yepellet zvakanyanya, izvo zvinondibatsira kusangana nezvinodiwa nevatengi. Iyo yepamusoro tembiricha yekudzora inochengetedza kunyungudika kuyerera kwakadzikama, saka ini ndinowana mashoma akaremara uye mamwe mayunifomu pellets.

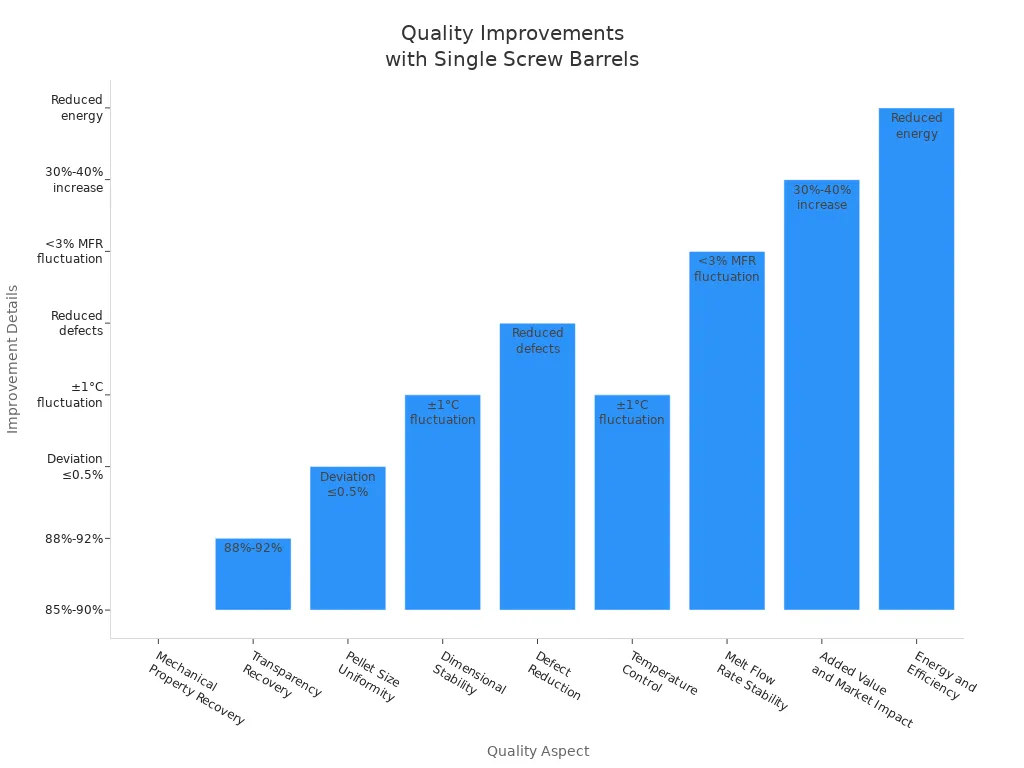

| Quality Aspect | Kuvandudza Details |

|---|---|

| Mechanical Property Recovery | 85% -90% yekudzoreredza mwero, yakakwira zvakanyanya kupfuura neyakajairwa michina |

| Transparency Recovery | 88% -92% kupora chiyero |

| Pellet Size Uniformity | Kutsauka kwehukuru mukati me0.5% |

| Dimensional Kugadzikana | Uniform tembiricha (± 1°C fluctuation) inovimbisa kugadzikana |

| Defect Reduction | Zvishoma tsvina uye kuremara |

| Temperature Control | Kudzora-nhanho-shanu, ± 1 ° C kuchinja |

| Melt Flow Rate Kugadzikana | Kuchinja kweMFR pasi pe3% |

| Yakawedzerwa Kukosha uye Musika Impact | 30% -40% kuwedzera kwekuwedzera kukosha |

| Simba uye Kubudirira | Kuderedza kushandiswa kwesimba, kushanda kwepamusoro |

Lower Maintenance uye Downtime

Ndakadzidza kuti kuchengetedza nguva dzose kunochengeta yangu imwe screw barrel yekudzokorodza granulation ichimhanya zvakanaka. Ndinotevera hurongwa hwekugadzirisa uye ndinoongorora dhiramu vhiki yega yega. Ini ndinogara ndichichengeta tembiricha uye screw kasi yakatsiga kudzivirira kushushikana pamushini. Yakachena, yakarongwa yepurasitiki feedstock inobatsira kudzivirira kukuvara kubva kune zvinosvibisa. Ndinochenesa uye ndinozora mativi anofamba kuti amise ngura nekukwesha. Pandinoona nhengo dzakasakara, ndinodzitsiva pakarepo. Ini ndinosarudza madhiramu akagadzirwa kubva kune akaomeswa alloys ane akakosha machira, senge nitriding, kuwedzera hupenyu hwavo.

- Weekly barrel inspectionschengeta midziyo yangu iri muchimiro chepamusoro.

- Tembiricha chaiyo uye kudzvanywa kunodzivirira kusakara.

- Yakachena feedstock inoderedza kukuvara kwemukati.

- Kugara kucheneswa nekuzora kumisa kuparara.

- Proactive chikamu kutsiva inodzivirira isingatarisirwe downtime.

- Aloys akaomarara uye machira anoita kuti dhiramu rigare kwenguva refu.

Zvirimwa zvinotevera matanho aya zvinoshuma nguva shoma uye kuderedza mari yekugadzirisa. Mutsara wangu wekudzokorora ikozvino unomhanya zvakanyanya uye nekuvimbika.

Nyaya Yechidzidzo: JT Single Screw Barrel mune Multi-Plastic Recycling

Ndakaisa JT single screw barrel yekudzokorodza granulation muchirimwa changu kubata mapurasitiki akasiyana sePE, PP, uye PVC. Izvo zvipfeko zvinodzivirira zvipfeko, zvakadai38CrMoAl uye tungsten carbide, vawedzera upenyu hwedhiramu. Ini zvino ndinopedza mari shoma pakugadzirisa uye kugadzirisa. Mutsetse wangu wekugadzira haumbomira, saka ndinosangana nemazuva angu ekutumira. Kuita kusingachinjiki kweJT single screw barrel yekudzokorodza granulation kwakavandudza kuburitsa kwangu uye nekudzikisa mitengo yangu. Ndinoona kuvhiringika kushoma uye zviri nanipellet quality, izvo zvinondibatsira kuti ndirambe ndichikwikwidza pamusika.

Ini ndinoona mabatiro anoita single screw barrels kugadzirisa akakosha kudzokorodza matambudziko. Chiitiko changu chinoratidza zvirinani kunyungudika, kusanganisa, uye kugadzikana kwemaitiro. Iine imwechete screw barrel yekudzokorodza granulation, ini ndinowana hunyanzvi hwepamusoro uye kuvimbika. Aya magadzirirwo anotsigira mashandiro ekuchenesa, mitengo yakaderera, uye inondibatsira kusangana nekukura kweindasitiri zvinodiwa zvekugadzirisazve mapurasitiki.

FAQ

Ndeapi mapurasitiki andinogona kugadzirisa neJT single screw barrel?

Ndinokwanisa kugadzira mapurasitiki akawanda, kusanganisira PE, PP, PS,PVC, PET, PC, uye PA. Iyo dhiramu inochinjika kune akasiyana midziyo yekunyatso dzokorora.

Ndoita sei kuderedza kusakara pascrew barrel yangu?

Ini ndinoshandisa mbiya dzakagadzirwa kubva kune yakaoma alloys ane nitrided kana bimetallic coatings. Kugara kuchenesa uye marongero akakodzera anondibatsira kuwedzera hupenyu hwebhari uye kuchengetedza kuita kwakakwira.

Sei kunyungudusa homogenization zvine basa mukudzokorodza?

Melt homogenization inondipa yunifomu pellets. Ndinoona hurema shoma uye nani chigadzirwa simba. Kusanganisa kusanganisa kunondibatsira kusangana nemhando yepamusoro uye zvinodiwa nevatengi.

Nguva yekutumira: Aug-21-2025