PE madiki ezvakatipoteredza granulators muna 2025 anoshandisa yakakwirira-inoshanda mota, process optimization, uye chaiyo-nguva otomatiki kucheka kushandiswa kwesimba. Vashandi vanoona mibairo yekukurumidza, senge a40% inodonha mukushandiswa kwesimba patanizvichienzaniswa netsikasingle screw machine or vented single screw extruderzvirongwa. Waste heat recovery inotsigirawoisina mvura granulator muchinamabasa.

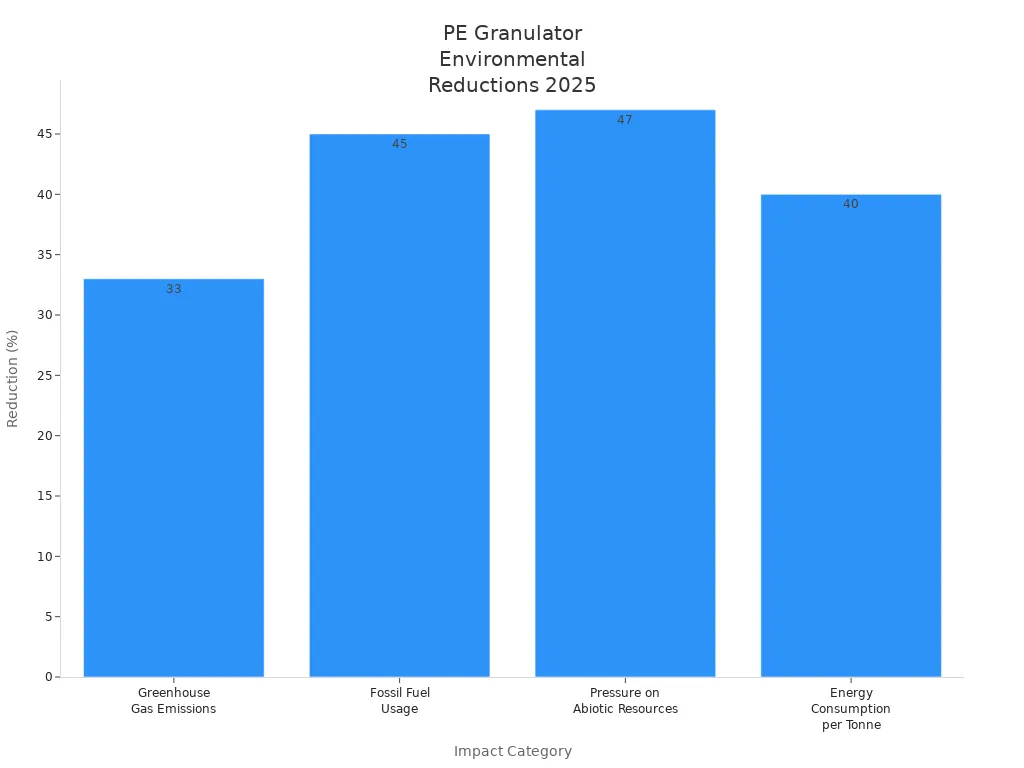

| Metric | Kuderedzwa Kwakaitwa muna 2025 Kuenzaniswa neMakore Apfuura |

|---|---|

| Greenhouse Gasi Kuderedzwa | 33% yakaderera |

| Fossil Fuel Usage Reduction | 45% yakaderera |

| Dzvinyiriro paAbiotic Resources | 47% yakaderera |

| Kushandiswa Kwemagetsi paTonne | Yakaderera se10 kW-h/tonne, 40% yakaderera pane yechinyakare michina |

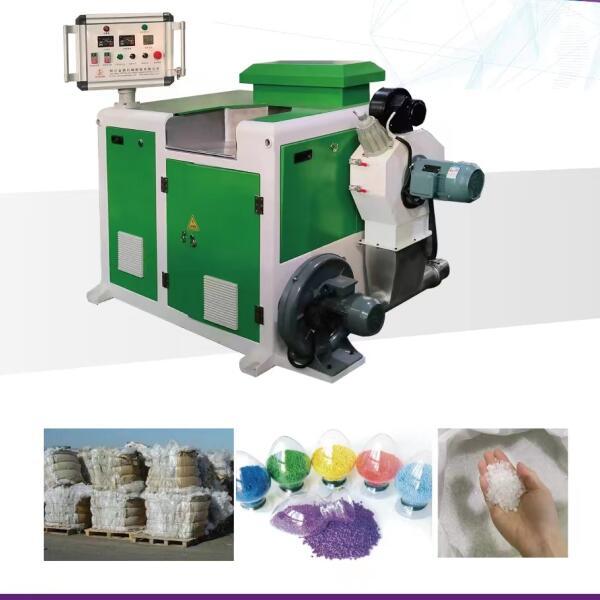

PE Diki Yezvakatipoteredza Granulators: Energy-Saving Technologies

High-Efficiency Motors uye Transmission Devices

PE madiki ezvakatipoteredza granulator muna 2025 vanovimba nazvomota dzepamusoro-soro uye michina yekufambisa yepamusorokuwana zvakakosha kuchengetedza simba. Aya mamotor anoshandura simba remagetsi kuita magetsi emagetsi nekurasikirwa kushoma, kuve nechokwadi chekuti mazhinji emagetsi ekuisa anotyaira maitiro egranulation. Zvishandiso zvekufambisa zvepamberi zvinowedzera kuwedzera kushanda uku nekugadzirisa mafambiro anoita simba kubva kumota kuenda kune yekucheka uye extrusion zvikamu. Kana akasanganiswa, matekinoroji aya anoderedza kushandiswa kwesimba rose panguva yekushanda. Kubatanidzwa uku kunoumba hurongwa hwakakwana hwekuchengetedza simba hunotsigira kushandiswa kwesimba shoma uye kubudirira kwekugadzirwa kwepamusoro. Vagadziri vanobatsirwa kubva kune yakaderera magetsi mabhiri uye yakagadziridzwa mashandiro emidziyo. Iko kushandiswa kwepamusoro-inoshanda mota uye michina yekufambisa zvakare inowedzera hupenyu hweiyo granulator, ichidzikisa zvinodiwa zvekuchengetedza uye nguva yekudzikira.

Zano:Kukwidziridza kumamotor akanyanya-anoshanda uye masisitimu ekufambisa anogona kucheka kushandiswa kwesimba kusvika ku30% zvichienzaniswa nemhando dzekare.

Intelligent Automation uye Process Optimization

Intelligent otomatiki inomira papakati peazvino PE madiki ezvakatipoteredza granulator. Aya masisitimu anoshandisa akangwara kudzora kutarisa uye kugadzirisa akakosha maratidziro ekuita senge tembiricha, kumhanya kwemota, uye vibration. Vashandi vanogona kuvimba nezvinhu zvakaita sePLC touch screens, izvo zvinobvumira shanduko ine simba kune tembiricha uye saizi yepellet. Masensa anoona zvinhu zvakaita sekuvhara kufa kana kuwandisa mota, kuderedza njodzi yenguva isingatarisirwe yekudonha.

- Smart granulator inodzora track performance zviratidzo zvekufungidzira kugadzirisa.

- AI-yakavakirwa masisitimu inozivisa kuronga kwekuchengetedza, senge nguva yekuchinja mapanga kana girisi mabhero.

- Cloud-based platforms inogonesa kutarisa kure uye kutumira zviyeuchidzo zvekugadzirisa.

- Power cabinet wiring inotsigira kubatanidza nyore nemimwe michina.

- Automation inoderedza kupindira kwemaoko, kuvandudza kuchengeteka uye kuvimbika.

- Process optimization yakanaka-tunes anoshanda parameter, streamlining granulation uye kuderedza kutambisa simba.

- Modular dhizaini inobvumira kugadzirisa kwezvinhu zvakasiyana uye zvinodiwa zvekugadzira.

Maitiro ekugadzirisa maitiro anowedzera kuwedzera simba rekushandisa. Yakabatanidzwa muchina madhizaini anosanganisa shredding, kucheka, extrusion, uye pelletizing kuita kumwe kuenderera kushanda. Iyi nzira inoderedza kushandiswa kwebasa, nguva, uye simba. Nzira dzekudya dzinoenderana dzinodzikamisa kuyerera kwezvinhu, kudzivirira kuderera uye kuvandudza kunaka kwekubuda. Otomatiki maficha senge otomatiki yekudyisa kudzora, maviri chiteshi mafirita, uye otomatiki-kugadzirisa yekumhanyisa banga inovimbisa kugadzirwa kwakanaka uye kwakanaka. Mota dzinoshanda nesimba, madhiraivha anochinja, uye masisitimu ekutonhodza epamberi anobatsirawo kuderedza kushandiswa kwesimba.

Waste Heat Kudzoreredza uye Kushandiswa

Tsvina kupisa kudzoreredza kunomiririra kufambira mberi kukuru muPE diki yezvakatipoteredza granulator. Munguva yekuita granulation, michina inogadzira kupisa seyakagadzirwa. Panzvimbo pokurega kupisa uku kupukunyuka, masisitimu echizvino-zvino anoatora ndokuishandisazve. Tekinoroji dzakadai semapombi ekupisa kwepamusoro-tembiricha uye masisitimu ekuchengetera kupisa akadzikama achishandisa chikamu chekuchinja zvinhu (PCMs) anodzoreredza kupisa kwetsvina yakaderera uye kuisimudzira kuti ishandiswe mukugadzira chiutsi kana kupisa nzvimbo. Mumafekitori ekuratidzira, mahybrid ekupisa pombi masisitimu akadzora pamusoro pe80% yekupisa tsvina, zvichideredza kuvimba nemagetsi kupisa kusvika pasi pe20%. Izvi hazvingonatsiridza kushanda kwesimba rose asiwo zvinounza kudzoka kwakasimba kwehupfumi, kazhinji kuzvibhadhara mukati memakore matatu. Iko kusanganiswa kwekuchengetedza kupisa uye kupisa pombi kunogonesa kuenderera mberi kwekushanda uye kutakura mitoro, kuwedzera kucheka mari yesimba uye kuderedza CO2 kubuda.

| Vadivelu Comedy Technology | Function | Impact paKushandisa Simba |

|---|---|---|

| High-Temperature Heat Pombi | Inovandudza kupisa kwemarara kune process steam | Inoderedza kupisa kwemagetsi |

| Latent Heat Storage (PCM) | Kuchengeta uye kuburitsa kupisa sezvinodiwa | Inogonesa kuchinja kwekutakura |

| Hybrid System | Inobatanidza zvose zviri zviviri kuti zvinyatsoshanda | Inodzorera 81.1% yekupisa kwemarara |

PE madiki ezvakatipoteredza granulator anoisa mwero mutsva wesimba rekushandisa mukugadzirisa kwepurasitiki. Tekinoroji dzavo dzepamusoro dzekuchengetedza simba dzinobatsira vagadziri kudzikisira mitengo, kuvandudza goho, uye kutsigira zvinangwa zvezvakatipoteredza.

Mabhenefiti ePE Diki Ezvakatipoteredza Granulator muna 2025

Yakaderedzwa Mari Yekushanda uye Kushandisa Simba

Vagadziri vanoona kucheneswa kwemutengo kwakajeka pavanoshandisa PE madiki ezvakatipoteredza granulator. Mienzaniso yemhepo inotonhorera inobvisa kudiwa kwemvura, iyo inochengetedza mari pakuchenesa mvura uye kuchengetedza michina. Aya magranulator anoshandisa simba shoma pane mvura-yakatonhodzwa masisitimu nekuda kwekugadzirwa kwayo kwakapfava uye nekuvandudza kushanda kwayo. Kuchengetedza kunova nyore, uye njodzi yekuputsika kubva kumatambudziko ehurongwa hwemvura inodonha. Vashandi vanogona kufambisa michina iyi munzvimbo dzine mvura shoma kana mhepo isina kunaka, zvichiita kuti kugadzirwa kurambe kwakadzikama. Kutonhodza kwakafanana kunovandudzawo kunaka kwechigadzirwa uye kunoderedza marara.

- Air-cooled operation inobvisa mari yemvura uye kugadzirisa kwakabatana.

- Kushandisa simba shoma kunoreva mabhiri madiki emagetsi.

- Chimiro chakareruka chinoderedza zvidikanwi zvekugadzirisa uye kuderera.

- Kuita kwakagadzikana munzvimbo dzakaoma kunovimbisa kuburitsa kwakavimbika.

- Zvirinani zvemhando yezvigadzirwa zvinotungamira kune kushomeka kwemarara uye kushanda kwakanyanya.

Environmental Impact uye Carbon Footprint Reduction

PE madiki ezvakatipoteredza granulator anobatsira makambani kuderedza maitiro avo ezvakatipoteredza. Vanocheka carbon emissions uyekushandiswa kwesimba, kuita kugadzirwa kwepurasitiki kusvibirira.

| Environmental Benefit | Detail |

|---|---|

| CO2 Emission Kuderedza | 1.5 tonnes CO2 yakaderedzwa patani yepellet yakagadziridzwa |

| Kuderedza Kushandiswa Kwemagetsi | 30% shoma simba rinoshandiswa netsva-yakaderera-speed granulators |

| Noise Reduction | 20dB yakaderera ruzha mazinga |

| Recycling Rate Improvement | Yakavharwa-loop recycling inoderedza kushandiswa kwezvinhu mbishi |

| Nyaya Muenzaniso - Motokari | 300 matani epurasitiki matsva anochengetwa gore negore nekudzoreredza tsvina yakawanda |

| Muenzaniso Wenyaya – Zvekurima | 85% yekushandura chiyero chakaitwa nevarimi vekuIndia vachishandisa mapelletizer madiki |

Michina iyi zvakare inotsigira hupfumi hwedenderedzwa nekushandura marara epurasitiki kuita magranules anogona kushandiswa zvakare. Iyi nzira inoderedza marara emarara uye inochengetedza zviwanikwa.

Kutevedzera uye Kugadziriswa kweIndasitiri Mitemo

PE madiki ezvakatipoteredza granulator anobatsira makambani kusangana nemitemo yakasimba yezvakatipoteredza mumatunhu mazhinji. Michina inotsigira kudzokorodza uye kuderedza kushandiswa kwemarara, izvo zvinoenderana nezvirongwa zvehurumende zvekurasa zero. Mazhinji mamodheru anosangana nezviyero zvepasi rose seISCC PLUS, iyo inoteedzera kushandiswa kwechikafu chekudya uye inova nechokwadi chekutevedzera magariro uye nharaunda zvinangwa. Dhizaini yavo inochinjika inokodzera ese makuru uye madiki mashandiro, kubatsira mabhizinesi kujairana nekuchinja mitemo. Advanced otomatiki uyemaitiro ekuchengetedza simbaita kuti zvive nyore kutevera mitemo mitsva pamusoro pezvinobudiswa uye ruzha. Makambani ari kuNorth America neEurope anoshandisa magranulator aya kutsigira zvibodzwa zvehupfumi hwedenderedzwa uye kusangana nemiyero yemuno neyepasirese.

PE madiki ezvakatipoteredza granulator anowana yakakwira simba nekushandisa yakaderera-kumhanya dhizaini, inogoneka maficha, uye yepamusoro soro tekinoroji. Michina iyi inobatsira maindasitiri kuderedza mitengo, kuderedza tsvina, uye kutsigira hupfumi hwakatenderedza. Makambani anosarudza aya granulator anovandudza kusimba, kusangana nemirau, uye kugadzira ramangwana rakachena.

FAQ

Iyo PE diki yezvakatipoteredza granulator inochengetedza sei simba?

Iyo granulator inoshandisa yakakwirira-inoshanda mota uye yepamusoro otomatiki. Izvi zvinoderedza kushandiswa kwemagetsi uye kuderedza marara panguva yekugadzirwa kwepurasitiki granule.

Zano:Kuchengetedza nguva dzose kunobatsira kuchengetedza simba rekuchengetedza simba.

Ko iyo granulator inogona kubata marudzi akasiyana emarara epurasitiki?

Ehe. Muchina uyu unotsigira zvinhu zvakasiyana-siyana zvepurasitiki. Vashandi vanogona kugadzirisa marongero emhando yega yega, kuve nechokwadi chekuenderana granulation uye kunaka kuburitsa.

Chii chekugadzirisa chinoda granulator?

Vashandi vanofanirwa kutarisa mota, mafirita akachena, uye kuongorora mashizha ekucheka nguva nenguva. Zvidzoreso zvakapusa uye modular zvikamu zvinoita kuti gadziriso iite nekukurumidza uye nyore.

Nguva yekutumira: Jul-17-2025