Plastiki jekiseni rekuumba screw barrel rinoita basa rakakura mukuumba kunyunguduka kwemhando uye kumhanya kwekugadzira. Mainjiniya vanotarisa paneInjection Molding Barreldhizaini yekusimudzira kuita. Vanoshandisa zvinhu zvakasiyana-siyanaSingle Screw Plastic Extruder MachineuyeSingle Screw Extrusion Machine. Sarudzo yega yega inobatsira michina kugadzirisa mapurasitiki zvirinani.

Plastic Injection Molding Screw Barrel Structure uye Performance

Mhando dzeBarel: Bimetallic vs. Integral

Kusarudza mhando yedhiramu chaiyo inogona kuita mutsauko mukuru munzira aPlastic Injection molding screw barrelanoita. Bimetallic barrels anoshandisa chigadziko chesimbi chakasimba chine alloy lining yakaoma mukati. Iyi dhizaini inochengetedza zvinhu zvakakosha uye inoita kuti vagadziri vatore nzvimbo chete yakasakara lining, izvo zvinoita kuti kugadzirisa kuve nyore uye kudhura zvakanyanya. Kukodzera pakati pemucheka nedhiramu kunofanirwa kuve kwakanyatso kuchengetedza kupisa kuyerera zvakanaka uye kudzivirira kufamba. Bimetallic mbiya dzinoshanda zvakanaka pakugadzirisa abrasive kana kusimbiswa mapurasitiki nekuti anoramba kupfeka uye anogara kwenguva refu.

Integral barrels inogadzirwa sechidimbu chimwe chete. Izvi zvinovapa kurongeka kwepamusoro uye kunyange kugovera kupisa pamwe chete nedhiramu. Ivo vanoita kuti zvive nyore kuisa uye kuchengetedza kudziyisa uye kutonhora masisitimu. Nekudaro, ivo vanoda akasimba ekugadzira zvidzoreso kuchengetedza mhando yepamusoro. Kana uchienzanisa maviri, madhiramu akabatanidzwa anopa kugadzirisa kuri nyore uye kupisa yunifomu, nepo bimetallic mbiya inopa zvirinani kupfeka kuramba uye nyore kutsiva chikamu.

| Performance Aspect | Integral Barrel | Bimetallic Barrel |

|---|---|---|

| Kuvaka | Single-chidimbu, yakakwirira kugadzira nemazvo | Base barrel ine replaceable alloy simbi bushing |

| Kugovera Kupisa | Uniform kupisa kugovera pamwe nebarrel axis | Heat conduction yakachengetedzwa kana bushing fit iri chaiyo |

| Pfeka Resistance | Standard kupfeka resistance | Kuwedzerwa kupfeka kuramba nekuda kwealloy simbi lining |

| Maintenance | Kuisa nyore nyore uye kugadzirisa kwekudziya / kutonhora masisitimu | Replaceable bushing inobvumira chikamu chiri nyore kutsiva |

| Kushandiswa Kwezvinhu | Inoda kunyatsojeka uye kunaka kwezvinhu | Inochengetedza zvinhu zvakakosha nekushandisa alloy simbi chete mumucheka |

Bimetallic mbiya dzinogara kwenguva refu kupfuura dzakabatanidzwa mbiya, kunyanya kana uchigadzira zvinhu zvakaomarara. Dhizaini yavo inoderedza nguva yekudzikira uye kutsiva mutengo, izvo zvinobatsira kuti kugadzirwa kurambe kuchimhanya zvakanaka.

Screw Geometry: L/D Ratio, Compression Ratio, uye Flight Dhizaini

Iyo geometry yesikuruu mukati mePlastiki Injection molding screw barrelmaumbirwo mapurasitiki anonyunguduka nekusanganiswa. Iyo L / D reshiyo, iyo inofananidza kureba kwescrew kune dhayamita yayo, inokanganisa kunyunguduka kufanana uye kusanganisa. Sikuru refu (yakakwirira L/D chiyero) inopa plastiki nguva yakawanda yekunyunguduka nekusanganisa, izvo zvinovandudza kunaka kwechigadzirwa. Nekudaro, kana iyo screw yakarebesa, inogona kukonzera kupisa kwekupisa, kunyanya nemapurasitiki anonzwa kupisa. Zvishandiso zvakaita sePVC nePOM zvinoda masikuru mapfupi kudzivirira kukuvadzwa, nepo mapurasitiki akazadzwa negirazi kana akakwirira-viscosity achibatsirwa kubva kune akareba screws uye yakasimbiswa yekusanganisa nzvimbo.

- Zvishandiso zvine kugadzikana kwakanaka kwekupisa zvinoshandisa masiruu akareba ekusanganisa zvirinani.

- Mapurasitiki anonzwa kupisa anoda masiruu mapfupi kana madhizaini eshinda.

- General chinangwa screws (L/D ~20:1) anoenderana nemapurasitiki akajairika asi anogona kuratidza kusiyana kwemavara.

- Barrier screws (L/D ~24:1) inovandudza kusanganisa kwemapurasitiki akasimbiswa.

- Separation screws (L/D ~ 18:1) inobatsira kupisa-sensitive zvinhu kudzivirira kushatisa.

- Kusanganisa screws (L/D ~22:1) inopa yunifomu kunyunguduka kune yakakosha mapurasitiki.

Iyo compression reshiyo inoyera kuti yakawanda sei screw inomanikidza plastiki. High-viscosity mapurasitiki anoda yakakwirira compression reshiyo kunyunguduka uye kusanganisa zvakanaka. Kugadzirisa reshiyo yekumanikidza kunobatsira kuenzanisa throughput uye mhando yechigadzirwa. Vagadziri vanowanzo tarisa uye nekunatsiridza screw dhizaini kuti ienderane nezvinodiwa zvezvinhu.

Screw ndege dhizaini zvakare inokosha. Rheologically optimized screws inovandudza kunaka kwekunyunguduka nekufananidza mafambiro ekuyerera kwepolymer. Inodzorwa Melt Delivery masisitimu anobatsira kudzora tembiricha yekunyungudika uye viscosity, kuderedza njodzi yekuora. Kusanganisa screws uye dynamic barrier screws inopa yunifomu kunyunguduka uye kudzivirira nzvimbo dzakafa, izvo zvinoita kuti purasitiki risapisa kana kubuda ruvara.

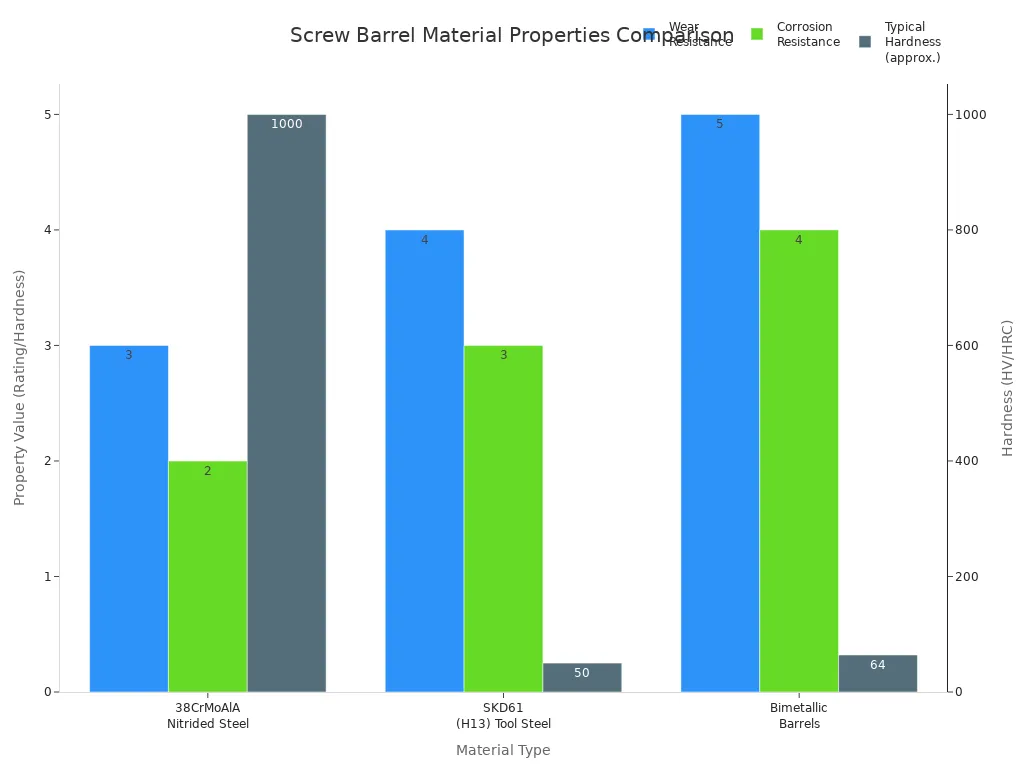

Kuumbwa Kwezvinhu uye Kurapa Kwepamusoro

Zvinhu zvinoshandiswa kugadzira Plastic Injection molding screw barrel zvinokanganisa kusimba kwayo uye kuita kwayo. Nitrided simbi inopa kunaka kuomarara uye kupfeka kuramba kweyakajairwa mapurasitiki. Bimetallic barrels inosanganisa chigadziko chesimbi chine alloy liner, ichipa kupfeka kwakanakisa uye kushomeka kwekupokana kwemapurasitiki akaoma kana akazara. Chishandiso chesimbi chinopa simba rakakwirira uye kupfeka kuramba kwenzvimbo dzakanyanyisa.

| Material Type | Key Properties & Pros | Cons & Limitations | Best Applications |

|---|---|---|---|

| Nitrided Steel | Kuoma kwepamusoro; zvakanaka kupfeka kupikisa kune resin isina kuzadzwa; inokwanisika | Kusaita ngura kusagadzikana; isingakodzeri abrasive/chemical resins | Commodity resins senge polyethylene, polypropylene |

| Bimetallic Barrels | Simbi inotsigirwa neine alloy liner; kupfeka kwakanakisa uye kusagadzikana kwemarara; hupenyu hurefu | More zvinodhura; inogona kunge yakanyanyisa kushandiswa | Naironi dzakazadzwa negirazi, ABS isingadzoreki mumoto, PVC, mapolima ane hasha |

| Nickel-Based Alloys | Exceptional corrosion resistance; yakanaka kune-flame-retardant uye halogenated resins | Zvishoma zvakaoma kudarika iron-based alloys; kushoma kupfeka kusagadzikana | Makemikari ane hukasha polima |

| Iron-Based Alloys | Superior kuoma uye kupfeka kuramba | Kudzikira kusimba kwekushomeka pane nickel-based alloys | Abrasive, yakanyatsozadzwa resins |

| Tool Steel | Kuomarara kwakasarudzika uye simba; kukwirira kupfeka kusagadzikana | High cost; inobatwa nekuora pasina machira | Kunyanya kupfeka nharaunda, yakakwirira-kubuda maapplication |

| Specialty Coated Barrels | Zvipfeko zvakadai se tungsten carbide kana chrome plating inovandudza kupfeka uye kusagadzikana kwemarara | Inowedzera mari uye kuoma; coating adhesion inosiyana | Tsika kana hukasha resin application |

Kurapa kwepamusoro senge nitriding uye chrome plating inowedzera kupfeka kuramba uye hupenyu hurefu. Nitriding inogona kupeta kana katatu hupenyu hwesevhisi yescrews nemadhiramu. Chrome plating inowedzera kuoma uye kusagadzikana kwemarara, asi nitriding inowanzoita zvirinani pasi pemamiriro ekuputika. Kupfapfaidza kwemolybdenum kwakasanganiswa ne nitriding kunopa dziviriro yakawedzera. Kushanda kwakanaka uye kugadzirisa kunobatsira kuwedzera mabhenefiti aya.

Kudyisa Port uye Venting Dhizaini

Iyo yekudyisa port dhizaini inodzora kuti plastiki inopinda sei mudhiramu. Kudzora tembiricha yakanaka pachiteshi chekudyisa inochengetedza viscosity yezvinhu, iyo inobatsira kuchengetedza kuyerera uye kudya. Vacuum loaders uye hopper inogamuchira inoita kuti zvinhu zvifambe zvakanaka mumushini, zvichideredza kusvibiswa uye kupera. Iyi seti inochengeta mhando yekugadzira yakakwira uye kudya kunoenderana.

- Vacuum loaders inokwira pahuro yemuchina, ichideredza kusvibiswa.

- Hopper vanogamuchira vanoshandisa giravhiti kudyisa zvinhu, kurerutsa maitiro.

Venting design inoitawo basa rakakosha. Vent screws ine nzvimbo dzakakosha dzinobvisa hunyoro uye kuparara panguva yekugadziriswa. Izvi zvakakosha kune hygroscopic zvinhu uye mapurasitiki akadzokororwa. Venting ports inoregedza magasi nehunyoro kutiza, kudzivirira kukanganisa uye kuchengetedza extrusion mhando yakakwirira.

Zano: Yakakodzera chiteshi chekudyisa uye dhizaini yekupinza mhepo inobatsira kuchengetedza kugadzirwa kwakatsiga uye kunatsiridza mhando yechigadzirwa, kunyanya kana uchishanda nemapurasitiki akadzokororwa kana anonzwa.

Performance Outcomes of Plastic Injection Molding Screw Barrel Design

Melt Hunhu uye Homogeneity

Yakagadzirwa zvakanaka Plastic Injection molding screw barrel inobatsira kugadzira yakatsetseka uye yakanyungudika. Iyo screw's geometry, kusanganisira yayocompression ratiouye chimiro chenzvimbo dzayo, inodzora kuti maplastic pellets anonyungudika nekusanganiswa sei. Kana iyo compression reshiyo inoenderana nezvinhu, iyo melt inoyerera zvakaenzana. Izvi zvinoderedza matambudziko akaita sema splay marks kana kunyungudika kusina kukwana. Thefeed zoneinofamba nekudziya mapellets, iyo compression zone inonyunguduka uye inodzvanya zvinhu, uye nzvimbo yemita inova nechokwadi chekuti kunyungudika kwakaenzana. Zvimiro zvakaita sekudzika kwechiteshi uye zvikamu zvekusanganisa zvinobatsira screw kupisa uye kusanganisa purasitiki. Barrier screws inogona kuparadzanisa mapurasitiki akasimba uye akanyungudutswa, zvichiita kuti kunyungudika kuwedzere kushanda uye kuchengetedza simba.

Kana iyo yakanyunguduka iri yunifomu, chigadzirwa chekupedzisira chinotaridzika zviri nani uye chinoshanda zviri nani. Kusanganisa kwakashata kunogona kukonzera mitsetse yemavara, mavara asina simba, kana shanduko muchikamu chehukuru. Good melt homogeneity inoreva zvikanganiso zvishoma uye zvikamu zvakavimbika. Vashandi vanogonawo kushandisa masensa kuti vaone kunyunguduka kwemhando uye kugadzirisa zvigadziriso kuti zvive nani.

- Kusakwana kunyunguduka kusanganisa kunokonzera mavara streaks uye asina simba mavara.

- Hunhu hwakanaka hwekunyunguduka hunotungamira kune inowirirana chikamu saizi uye kusimba.

- Melt mhando inoenderana nekupisa kwembiya, screw speed, uye backpressure.

Ongorora: Kuchengeta tembiricha yakanyunguduka yakatsiga uye kuenzanisa screw dhizaini kune rudzi rwepurasitiki kunobatsira kudzivirira kukanganisa uye kuchengetedza chigadzirwa chakakwira.

Kusanganisa Kubudirira uye Nguva Yekutenderera

Kusanganisa kushanda zvakanaka kunoenderana nechimiro che screw uye akakosha maficha. Sezvo screw inotendeuka, inosundidzira nekupeta purasitiki, ichigadzira yakasimbashear forces. Kusanganisa zvikamu padhuze nemuromo, semapini kana ndege dzinodzivirira, zvinobatsira kusanganisa kunyungudika. Ichi chiito chinoparadzira ruvara uye zvinowedzera zvakaenzana, saka chikamu chekupedzisira chinotaridzika uye chakafanana. Mabarrier screws anoshandisa ndege yechipiri kuparadzanisa plastiki yakanyunguduka kubva kune yakasimba, ichikurumidza kunyunguduka uye kudzivirira machunks asina kunyungudika.

- Screw geometry inodzora mafambiro, kunyungudika, uye kusanganiswa kwepellets.

- Kusanganisa zvikamu zvinogadzira kufamba kwe looping,kusanganiswa kwe95%yezvinyorwa nokukurumidza.

- Barrier screws uye akakosha madhizaini anobatsira kuparadzira ruvara uye zvinowedzera.

Kusanganisa kushanda zvakanaka kunokanganisawo nguva yekutenderera. Nekukurumidza uye zvakanyanya kunyungudika zvinoreva kuti muchina unogona kumhanya akawanda madhiraini munguva shoma. Kushandisa zvivhariso screws, hombe dhayamita screws, kana kudzika grooves kunowedzera plasticizing kumhanya. Kusimudza screw kumhanya (kana yakachengeteka kune icho chinhu) uye kuderedza kumashure kumanikidza kunogona zvakare kupfupisa nguva yekutenderera. Yepamberi yekudziisa uye yekutonhodza masisitimu inochengeta dhiramu patembiricha chaiyo, zvichibatsira kuti zvikamu zvitonhore nekukurumidza uye kuchengetedza kugadzira kuchifamba.

- Optimized screw barrel dhizaini inodzivirira kuvhara uye kunonoka.

- Kudziisa uye kutonhodza masisitimu anobatsira zvikamu kusimba nekukurumidza.

- Zvinhu zvinogara kwenguva refu uye mabhanhire zvinoderedza nguva yekugadzirisa.

Pfeka Resistance uye Maintenance

Kupfeka kunetseka kukuru kune chero Plastic Injection molding screw barrel. Abrasive fillers, corrosive plastics, uye marefu ekugadzira anomhanya anogona kupera pasi screw nedhiramu. Zvipfeko zvakajairika zvinosanganisira kupfeka anonamira, abrasive kupfeka, uye ngura. Semuyenzaniso, kupfeka kweabrasive kunoitika kana mafirita akaomarara segirazi faibha achikwesha pasimbi. Corrosive kupfeka kunobva kumakemikari mumapurasitiki sePVC.

| Pfeka Mechanism | Tsanangudzo | Dhizaini Mitigation Strategies |

|---|---|---|

| Adhesive Wear | Metal nzvimbo dzinosangana uye kutamisa zvinhu. | Shandisa hardfacing alloys, tarisa kugova, simbisa kuenderana kwezvinhu. |

| Abrasive Wear | Kuveura chiito kubva pamapellets kana mafiritsi. | Shandisa ma alloys akaomarara, dzivisa abrasive fillers, chengeta feedstock yakachena. |

| Corrosive Wear | Kurwiswa kwemakemikari kubva kune mamwe mapurasitiki. | Shandisa zvinhu zvinodzivirira kuora, dzivisa makemikari ane hutsinye. |

| Alignment Nyaya | Misalignment inokonzera kukwesha uye kusapfeka kwakaenzana. | Ita shuwa kutwasanuka uye kurongeka kwakaringana. |

Kusarudzwa kwezvinhu uye kurapwa kwepamusoro kunoita musiyano mukuru. Liquid nitriding inowedzera kuomarara kwepasi uye kupfeka kuramba. Bimetallic barrels ane chaiwo liners anogara kwenguva refu, kunyanya nemapurasitiki akaoma. Kugara uchiongorora uye kuchengetedza kwekudzivirira, sekuchenesa uye kutarisa kurongeka, zvinobatsira kubata matambudziko nekukurumidza. Majasi epamberi uye zvinhu zvitsva zvinogona kuwedzera hupenyu hwemadhiramu kusvika ku40%, kudzikisa mutengo wekugadzirisa uye kuderedza nguva.

- Maintenance frequency inoenderana nedhiramu zvinhu uye machira.

- Kuchengetedza kwekudzivirira uye kuongorora nguva dzose kunowedzera hupenyu hwemadhiramu.

- Mishonga yepamusoro yepamusoro inoderedza kugadzirisa uye kutsiva.

Kuchinjika kune Zvimwe Zvishandiso uye Mashandisirwo

Iyo inochinjika screw barrel dhizaini inoita kuti vagadziri vagadzirise akawanda marudzi emapurasitiki. Screw geometry, senge kureba, gomo, uye kudzika kwechiteshi, inogona kuchinjwa kuti ienderane nezvinhu zvakasiyana. General-chinangwa, chipingamupinyi, uye kusanganisa screws chimwe nechimwe chinoshanda zvakanyanya nemamwe mapurasitiki. Kutonhodza masisitimu, senge nzira dzemvura, chengeta dhiramu patembiricha chaiyo yechinhu chimwe nechimwe.

- Screw dhizaini uye geometryfananidza mapurasitiki akasiyana.

- Zvirongwa zvekutonhodza zvinodzivirira kupisa.

- High-simba alloys uye machira anobata mamiriro akaoma.

Madhizaini anochinjika zvakare anoita kuti zvive nyore kuchinja pakati pemabasa. Zvimiro zvakaita semaadapter anokurumidza-dimbura uye screw pusher anobatsira vafambisi kuchinja masiruuru nekukurumidza. Adaptive process controls inoshandisa masensa uye muchina kudzidza kugadzirisa marongero munguva chaiyo. Izvi zvinoderedza shanduko yemanyorero uye nekumhanyisa shanduko, saka kugadzirwa kunogona kuchinja kubva pane chimwe chinhu kana chigadzirwa kuenda kune chimwe nekuderera kushoma.

Zano: Anochinjika screw barrel dhizaini anobatsira mafekitori kubata akawanda marudzi emapurasitiki uye kushandura mabasa nekukurumidza, kuchengetedza kugadzirwa kuchinjika uye nemazvo.

Troubleshooting Common Performance Issues

Kunyange nekugadzirwa kwakanakisisa, matambudziko anogona kuitika. Nyaya dzakajairika dzinosanganisirakupfeka zvakanyanya, matambudziko etembiricha, kuvharika, ruzha, uye kukanganisa kusanganisa ruvara. Dambudziko rega rega rine zvikonzero zvaro uye mhinduro.

| Performance Nyaya | Tsanangudzo uye Zviratidzo | Zvikonzero uye Mhinduro |

|---|---|---|

| Kunyanya Kupfeka | Kudonha kwezvinhu, hurombo husina kunaka, kupisa kwakanyanya, ruzha | Shandisa bimetallic barrels, hardfacing alloys, kuchenesa nguva dzose, kurongeka kwakakodzera |

| Tembiricha Regulation | Discoloration, charring, bubbles, warping | Kamura mbiya muzvikamu, shandisa masensa, zvishoma nezvishoma preheating, insulation jaketi |

| Kuvhara uye Kuvaka-Up | Kudzvinyirirwa kwepamusoro, kuyerera kusina kunaka, mavara madema | Chenesa nemakomisheni ekugezesa, screw speed chaiyo, seal barrel panguva yekudzika |

| Noise kana Vibration | Ruzha rukuru, kudedera, kukwenya | Ongorora kurongeka, mabhengi, shandisa vibration damping, patsanura zvikamu |

| Kusanganiswa Kwemavara / Kusvibiswa | Mitambo yemavara, mithunzi isingaenderani, kusvibiswa | Shandisa macomputer ekuchenesa, kuchenesa nguva dzose, optimize screw dhizaini, zvisimbiso michina panguva yekuvhara |

Vashandi vanogona kugadzirisa matambudziko akawanda nekutevera mashoma akakosha matanho:

- Optimize screw configuration uye mbiya tembiricha nzvimbo.

- Monitor uye gadzirisa tembiricha uye screw speed.

- Calibrate ma feeder uye kudzivirira kubatanidza zvinhu.

- Ongorora masiruu nemadhiramu zvekupfekwa, kunyanya munzvimbo dzinenge dzanyanya kushushikana.

- Shandisa fungidziro yekugadzirisa kuronga kugadzirisa uye kuderedza nguva.

- Chengeta siruuruuye gadzirisa kashoma.

- Dzidzisa vashandi kuti vaone zviratidzo zvekukasika.

Cherechedza:Kugara uchicheneswa, kuzora mafuta zvakanaka, uye kunyatsoongororabatsira kuchengeta Plastic Injection molding screw barrel ichimhanya zvakanaka uye kuwedzera hupenyu hwayo.

Kugadzirisa chimiro chePlastiki Injection molding screw barrel inosimudzira kunyungudika uye hupenyu hwemidziyo. Kana vagadziri vanosarudza iyoRudyi mbiya mhando, screw geometry, uye zvinhu, vanoona kuyerera kwakatsetseka, kusanganisa kuri nani, uye kuremara kushoma. Kugara uchigadzirisa, kusanganisira kuchenesa nekuongorora, kunoita kuti michina irambe ichishanda zvakanaka uye inoderedza mitengo.

FAQ

Chii chinonyanya kukosha chebimetallic screw barrel?

Bimetallic mbiya dzinoramba kupfeka kubva kumapurasitiki akaoma. Vanogara kwenguva refu uye vanoderedza nguva yekuderedza kuchengetedza.

Kangani vashandisi vanofanirwa kuongorora screw barrel?

Vashandi vanofanirwa kutarisa screw barrel mwedzi wega wega. Kugara uchiongorora kunobatsira kubata kusakara nekukurumidza uye kuita kuti michina ishande zvakanaka.

Ko imwe screw barrel ingashanda nemhando dzakawanda dzemapurasitiki?

| Bharel Type | Kuchinjika |

|---|---|

| General Chinangwa | Kugona |

| Chipingamupinyi | Excellent |

| Kusanganisa | Kugona chose |

Bhari rakagadzirwa zvakanaka rinogona kubata mapurasitiki akawanda, asi zvimwe zvinhu zvinoda zvakakosha.

Nguva yekutumira: Aug-25-2025