Rabhoritari imwe screw extruder inoshandisa sikururu inotenderera kunyungudusa, kusanganisa, uye kugadzira mapolima mukati medhiramu rinopisa. Vatsvakurudzi vanovimba nevented single screw extruder, single screw machine,uyeisina mvura granulator muchinakuti uwane kusanganisa kwakakwana uye yakachengeteka, inoshanda kugadzirisa. Zvidzidzo zvinoratidza izvozvoscrew speed uye tembirichakukanganisa zvakananga chigadzirwa kunaka uye kuchengeteka.

Zvikamu Zvikuru zve Single Screw Extruder

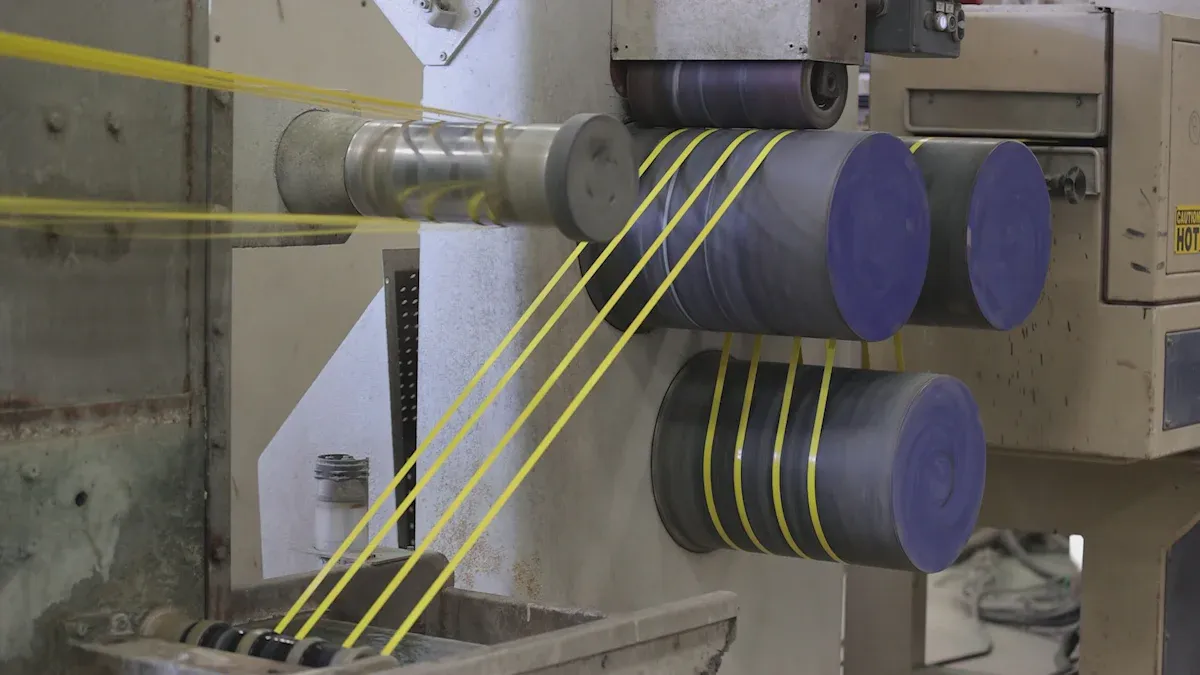

The Screw

The sikuruundiwo mwoyo we single screw extruder. Inotenderera mukati medhiramu uye inofambisa iyo polymer mberi. Iyo screw inonyunguduka, inosanganisa, uye inosundira zvinhu kudhishi. Screw dhizaini, inosanganisira dhayamita, kureba-kusvika-dhayamita reshiyo, uye compression reshiyo, inokanganisa kuti iyo polymer inonyungudika sei uye musanganiswa. Iyo screw yakagadzirwa zvakanaka inovandudza kunyunguduka uye kushanda zvakanaka. Grooves pane screw kana barrel inogona kuwedzera kunyungudika nekukurumidza uye kubatsira kudzora maitiro. Iyo screw speed inoshandurawo huwandu hwekusanganiswa uye kupisa kunogadzirwa.

Zano: Kugadzirisa screw kumhanya kunogona kubatsira kudzora tembiricha yekunyunguduka uye mhando yechigadzirwa.

The Barrel

Chirongoinotenderedza sikuruu uye inobata iyo polima painofamba. Iyo dhiramu ine tembiricha nzvimbo dzakasiyana. Imwe neimwe nzvimbo inogona kusetwa kune chaiyo tembiricha kubatsira kunyungudutsa iyo polymer zvakaenzana. Semuenzaniso, nzvimbo yekutanga inogona kutonhorera kubatsira kufambisa iyo yakasimba polymer, nepo nzvimbo dzepashure dzichipisa kunyungudutsa zvinhu. Kudzora kwakakodzera kwekushisa mubhodhoro kwakakosha pakuyerera kwakanaka uye kunaka kwechigadzirwa.Thermocouples inoyera tembiricha mukati medhiramukuchengetedza nzira yakagadzikana.

- Kugadzika tembiricha yebhari zvinoenderana nerudzi rwepolymer uye screw dhizaini.

- Mazuva ano extruder kazhinji ane matatu kana anopfuura tembiricha nzvimbo.

- Chikamu chekudya chinofanira kunge chichidziya asi kwete kunyanya kupisa kudzivirira zvinhu zvakanamatira.

Iyo Heater System

Iyo heater system inochengeta dhiramu patembiricha yakakodzera. Heaters anoiswa pamwe chete nedhiramu uye anodzorwa nemasensor. Iyo sisitimu inogona kugadzirisa imwe neimwe nzvimbo kuti ienderane nezvinodiwa zvepolymer. Yakanaka heater control inobatsira kudzivirira matambudziko sekutsva kwezvinhu kana kunyungudika zvisina kuenzana. Iyo heater system inoshanda neiyo control system kuchengetedza maitiro akachengeteka uye anobudirira.

The Die

Iyo inofa inoumba iyo yakanyungudutswa polima sezvo ichisiya imwe screw extruder. Dhizaini yekufa inokanganisa chimiro chekupedzisira chechigadzirwa, pamusoro, uye saizi. Kufa kwakanaka kunopa kutsetseka, kuyerera uye kunobatsira kugadzira zvigadzirwa zvine zviyero zvakaringana. Iyo inofa inofanirwa kubata tembiricha yakakodzera uye kudzvanywa kudzivirira kukanganisa. Kuchinja kwekushisa kwekufa kana kuyerera kunogona kushandura kunaka kwechigadzirwa.

- Uniform velocity uye kushomeka kudonhedza kudonhedza panofa kubuda kwakakosha kune mhando.

- Die chiteshi geometry uye kuyerera kwechiyero kunokanganisa iko kurongeka kwechigadzirwa chimiro.

The Control System

Iyo yekudzora sisitimu inogadzirisa iyo imwechete screw extruder's mashandiro. Inotarisa tembiricha, kudzvanywa, screw speed, uye chiyero chekudya. Vashandisi vanoshandisa iyo control system kuseta uye kugadzirisa maitiro paramita. Real-time monitoring inobatsira kuchengetedza maitiro akagadzikana uye akachengeteka. Iyo yekudzora sisitimu inogona zvakare kuchengetedza mabikirwo emapolymer akasiyana, zvichiita kuti zvive nyore kudzokorora akabudirira kumhanya.

Mhando dzeSingle Screw Extruder Yekushandisa muLabhoritari

Zvigadziriso zverabhoritari zvinoda marudzi akasiyana evaextruder kuti asangane nezvinodiwa zvekutsvagisa. Mhando yega yega inopa akasiyana maficha uye mabhenefiti epolymer kugadzirisa.

Vented Single Screw Extruder

A vented single screw extruder inoshandisa amaviri-nhanho screw design. Iyi dhizaini inoderedza torque uye bhiza zvinodiwa uku uchichengetedza kubuda uye screw kumhanya. Iyo venting system inobvisa hunyoro uye magasi kubva ku polymer melt. Iyi nhanho yakakosha pakugadzirisa mapurasitiki anotora mvura. Kubvisa izvi zvinoputika zvinodzivirira kukanganisa senge splay uye isina simba mechanical properties. Iyo vent port inowanzoshanda pasi pevacuum, iyo inobatsira degassing nekudzikisa kudzvanywa. Iyo-matanho maviri screw zvakare inovandudza kusanganisa nekumanikidza uye decompressing epurasitiki. Iyi nzira inogadzira imwe yunifomu kunyunguduka. Vashandi vanofanirwa kuenzanisa zvinobuda pakati pematanho maviri kuti vadzivise kukwira kana kubuda mafashama. Aya maficha anoita kuti mhepo imwe chete sikuruwe extruder ishande uye yakavimbika mumarabhoritari application.

Ongorora: Yakagadzika kubuda uye yakaderera simba kushandiswa kwakaisa vented extruders munzvimbo dzekutsvagisa.

Single Screw Machine

Iyo imwechete screw muchina inovhara huwandu hwakasiyana hweextruder hwekunyungudusa, kusanganisa, uye kuumba mapolymer. Michina iyi inopa dhizaini iri nyore uye kushanda kuri nyore. Vatsvagiri vanogona kudzora shear uye tembiricha zvakanaka, iyo inobatsira neyakaomesesa polymer maumbirwo uye extrusion mabasa. Single screw machines inoshanda nemazvo kugadzira tubing, firimu, uye zvimwe zvigadzirwa zviri nyore. Iwo anouya muhukuru hwakasiyana uye masisitimu kuti aenderane akasiyana siyana ekutsvagisa zvinodiwa.

| Extruder Type | Hunhu Hunokosha uye Zvakanakira | Yakajairika Maapplication uye Kukodzera |

|---|---|---|

| Single Screw Extruders | Dhizaini iri nyore, kutonga kwakanaka, kushanda kuri nyore | Tubing, firimu, basic polymer formulations |

| Twin Screw Extruders | Superior kusanganisa, zvakasiyana-siyana, intermeshing screws | Kubatanidza, zvinhu zvakaoma, mishonga yemishonga |

| Miniature / Micro Extruders | Zvidiki-zvidiki, zvinodhura, zvinovimbika | R&D, prototyping, mashoma emhando masampuli |

Mvura isina mvura Granulator Machine

Muchina usina mvura wegranulator unoshandura zvinhu zvepurasitiki kuita magranules pasina kushandisa mvura. Iyi tekinoroji inovandudza kugona kwesimba uye inoderedza kukanganiswa kwezvakatipoteredza. Iyo nzira inochengeta magranules akaoma uye akachena, izvo zvinobatsira mamwe matanho ekugadzirisa. Michina isina mvura granulator inobata akawanda marudzi epurasitiki resin. Ivo vanobatsira vanotsvaga kuburitsa emhando yepamusoro granules yekuyedza nekusimudzira.

Nhanho-ne-Nhanho Polymer Extrusion Maitiro

Kudyisa iyo Polymer Material

Iyo extrusion maitiro anotanga nekudyisa iyo mbishi polymer zvinhu muhopper yekudyisa. Iyo hopper inovimbisa kunyangwe kugovera uye inodzivirira blockages, iyo inobatsira kuchengetedza yakadzikama throughput. Iyo screw mukati medhiramu inotanga kutenderera, ichikwevera mapolymer pellets kana hupfu kumberi. Dhizaini ye screw, kusanganisira dhayamita yayo uye kureba-kusvika-dhayamita reshiyo, inoita basa rakakosha mukufamba zvakanaka kwezvinhu. Iyo yekudzora sisitimu inobvumira vashandisi kugadzirisa screw kumhanya uye chiyero chekudyisa, iyo inobatsira kukwenenzvera maitiro emapolymer akasiyana.

- Feed hoppers dzakagadzirirwa kudzivirira kuvhara uye kuve nechokwadi chekudyisa kwakanaka.

- Iyo screw inoburitsa, inomanikidza, uye inotanga kupisa iyo polymer.

- Kudzora tembiricha mudhiramu kunobatsira kukwenenzvera kunyungudika.

Zvidzidzo zvepakutanga zvakaratidza kuti kudzora kumhanya kwescrew uye tembiricha zvinokanganisa zvakananga madyiro uye kunyungudika kwepolymer. Mazuva ano murabhoritari extruder anoshandisa zvidzoreso zvepamberi kuchengetedza kudya kwakanaka uye kwakagadzikana.

Kunyunguduka uye Plasticizing

Sezvo iyo polima inofamba ichitevedza dhiramu, inopinda munzvimbo dzinopisa. Tembiricha munharaunda yega yega inowedzera zvishoma nezvishoma, zvichiita kuti iyo polymer ipfave uye inyunguduke. Kutenderedzwa kwesiruu nekupisa kwebhororo zvinoshanda pamwechete kugadzira zvinhu zvepurasitiki, zvichirishandura kuita yunifomu yakanyungudutswa. Masensa akaiswa padivi pembiru anotarisisa tembiricha uye kudzvanywa kuti ive nechokwadi chekuti polymer inonyungudika mukati meiyo yakanakira kugadzirisa renji.

| Parameter | Tsanangudzo |

|---|---|

| Melt Temperature | Inofanirwa kugara mukati meiyo polymer's process renji kuti uwane mibairo yakanaka. |

| Kudzvanya Pamusoro peScrew | Inoratidza kunyunguduka kunaka uye kugadzikana kwemaitiro. |

| Kuchinja Kwekumanikidza | Inotariswa kuona chero nyaya nekunyunguduka kana kuyerera. |

| Temperature Fluctuations | Inoteverwa kuti ive nechokwadi chekudziya uye kudzivirira kukanganisa. |

| Degree yekunyungudika | Yakatariswa nekuona kana nekuyedza extruded firimu kuti ijekese uye yakafanana. |

| Screw Performance Index | Inosanganisa zvinhu izvi kuyera kunyungudika kwemhando kubva pahurombo (0) kuenda kune yakanaka (1). |

Kunyatso kudzora tembiricha uye kudzvanywa kunobatsira kudzivirira kudzikira uye kunovimbisa kunyungudika kunoenderana. Real-time yekutarisisa ine advanced sensors uye spectroscopy matekiniki inopa inoenderera data, ichibvumira vaongorori kugadzirisa marongero sezvinodiwa.

Kusanganisa uye Kutumira

Kana yanyungudutswa, iyo polymer inofanirwa kusanganiswa zvakakwana kuti ive nechokwadi chekufanana. Iyo screw dhizaini, inosanganisira maficha senge zvipingamupinyi zvikamu kana kusanganisa nzvimbo, inobatsira kusanganisa zvinhu uye kubvisa chero zvidimbu zvakasara zvakasimba. Sezvo screw inotenderera, inosundira iyo polima yakanyungudutswa mberi, ichiendesa kune kufa.

Vatsvagiri vanoshandisa advanced setups nesampling ports uye optical detectorskudzidza kuti zvinhu zvinosanganiswa sei. Nekubaya matracer uye kuyera kuti anopararira sei, vanogona kuona kuti screw speed uye geometry zvinokanganisa sei kusanganisa. High screw kumhanya dzimwe nguva inogona kusiya zvimedu zvakasimba, asi yakakosha screw dhizaini inovandudza kusanganisa uye kudzivirira nyaya iyi.Kudzvanya masensa pamwe chete nedhiramukuyera mafambiro epolymer, zvichibatsira vashandisi kukwenenzvera maitiro.

Kugadzira Kuburikidza neDie

Iyo polima yakanyungudutswa inosvika kufa, iyo inoigadzira kuita fomu yaidiwa. Dhizaini yedhizaini inosarudza saizi yechigadzirwa chekupedzisira uye mhando yepamusoro. Mainjiniya anoshandisa kuenzanisa kwemakombuta uye kupenengura chinhu chekuongorora kugadzira anofa anoburitsa maumbirwo akakwana uye kuderedza hurema. Ivo zvakare vanokwidziridza iyo inoyerera chiteshi geometry kuti ienzanise velocity uye kuderedza mamorekuru ekutarisa misiyano, iyo inogona kukanganisa zviyero zvechigadzirwa.

| Evidence Aspect | Tsanangudzo |

|---|---|

| Finite Element Analysis | Inoshandiswa kudzidza kuyerera uye kuumba kurongeka mukufa. |

| Optimization Design | Inoderedza zvikanganiso uye inovandudza geometric precision. |

| Kuedzwa Kusimbiswa | Inosimbisa kutonga kwakasimba kwehukuru hwechigadzirwa. |

| Numerical Simulation | Kufanotaura kufa kuzvimba uye interface kufamba kune zvirinani mhedzisiro. |

| Molecular Orientation Control | Zviyero zvinoyerera kudzivirira kusaenzana kutambanudza uye kuchinja kwechimiro. |

Kunyatso kudzora kweiyo inofa uye yakadzika midziyo inoita kuti chigadzirwa chisiyeSingle Screw Extrudernechimiro uye saizi chaiyo.

Kutonhodza uye Kusimbisa

Mushure mekuumbwa, iyo inopisa polymer inobuda mufa uye inopinda muchikamu chekutonhora. Kutonhodza kunoomesa iyo polymer, ichikiya muchimiro chayo chekupedzisira uye zvivakwa. Mwero wekutonhora unoenderana neextrusion tembiricha, ambient mamiriro, uye kumhanya uko chigadzirwa chinofamba nemunzvimbo yekutonhora.

| Parameter/Aspect | Observation/Chigumisiro |

|---|---|

| Extrusion tembiricha | Polymer yakawedzerwa pa100 ° C |

| Ambient tembiricha | Yakachengetwa inenge 20 °C panguva yekuedza |

| Kutonhora kwepamusoro peak tembiricha | Kunenge 72 °C |

| Effect of velocity | Lower velocities anononoka kutonhora uye anowedzera solidification nguva |

| Kutonhodza mwero maitiro | Maximum rate inodonha sezvo velocity inoderera; peak inochinja kune nguva refu |

| Multi-layer effect | Gare gare zvikamu zvinogona kupisa zvekare zvekare, zvichivandudza kunamatira |

Kuchengeta nzvimbo dzekutonhodza mukati metembiricha yakatetepa, kazhinji mukati me ±2°C, kunobatsira kuve nechokwadi chemhando yechigadzirwa. Kutonhodza kwakaringana kunodzivirira kuputika uye kunoita kuti iyo polymer inosimba zvakaenzana.

Zvishandiso zveSingle Screw Extruder muPolymer Research

Material Formulation and Testing

Vatsvagiri vanoshandisa murabhoritari extruders kugadzira uye kuyedza mitsva yepolymer musanganiswa. Zvidzidzo zvekutanga uye patents zvinotsanangura kuti seiscrew designuye kutonga kwekupisa kunovandudza kunyunguduka nekusanganiswa. Magadzirirwo aya anobatsira masayendisiti kugadzira zvinhu zvitsva zvine chaiwo zvivakwa. Semuenzaniso, yakaderera-inogoneka extruder yakavakwa nezvinhu zvemuno yakaratidza kushanda kwakasimba mukugadzira lab-scale. Yakagadziriswa kusvika ku13 kg neawa uye yakaderedza zvisingadiwi makomisheni muchigadzirwa chekupedzisira. Mhedzisiro iyi inosimbisa kuti marabhoritari extruders inotsigira zvese hunyanzvi uye kutonga kwemhando mukugadzira zvinhu.

| Parameter | Kukosha/Chigumisiro |

|---|---|

| throughput | 13.0 kg/h |

| Kukurura Speed | 200 rpm |

| Bharel Diameter | 40 mm |

| Wedzero yekuwedzera | 1.82–2.98 |

| Trypsin Inhibitor Kuderedza | 61.07%–87.93% |

Process Optimization

Laboratory extruders inobatsira masayendisiti kuwana akanakisa maitiro ekugadzirisa mapolymer akasiyana. Experimental data inoratidza izvozvokushandiswa kwesimba kunoenderana nekumhanya kwescrew uye zvinhu zvenyama. Nekurekodha simba remota uye kugadzirisa marongero, vaongorori vanogona kuvandudza kugona kwesimba uye mhando yechigadzirwa. Zvidzidzo zvakare zvinoratidza kuti kuchinjascrew speeduye kuwedzera zvimwe zvinongedzo zvinogona kuvandudza masanganisire epolymers nekuyerera. Izvi zvakawanikwa zvinobatsira zvikwata kumisa yakachengeteka, inoshanda, uye inodzokororwa maitiro ezvese kutsvagisa nekugadzira.

Zano: Kugadzirisa screw kumhanya uye tembiricha inogona kuenzanisa kushandiswa kwesimba uye kugadzirisa chigadzirwa.

Diki-Scale Product Prototyping

Lab extruders inoita kuti zvive nyore kugadzira mabheti madiki ezvigadzirwa zvitsva. Matimu anogona kudzora tembiricha, kudzvanywa, uye screw kumhanya kune zvakavimbika mhedzisiro. Iyi nzira inochengetedza mari uye inokurumidza kusimudzira. Vatsvakurudzi vanogona kukurumidza kuedza mazano matsva uye kuwedzera vakabudirira. Compact extruder zvakare inobvumira shanduko inoshanduka mune zvinhu kana dhizaini. Kufambira mberi mune otomatiki uye chaiyo-nguva yekutarisa inowedzera kuvandudza maitiro ekudzora uye kuderedza tsvina.

- Kudzora kwakaringana pamusoro pemaitiro paramita

- Inodhura-inoshanda uye inokurumidza prototyping

- Kugadziriswa kuri nyore kwezvinhu zvakasiyana

- Kuwedzeredzwa kwemhando yechigadzirwa uye kufanana

Mazano Ekushanda uye Matambudziko eSingle Screw Extruder

Kugadzira iyo Extruder

Kugadzika kwakakodzera kunovimbisa kushanda kwakavimbika uye kunowedzera hupenyu hwemidziyo. Nyanzvi dzinotevera idzimatanho ekushanda kwakakwana:

- Isa screwsmunzvimbo dzavo dzepakutanga uye edza screws itsva pa low speed isati yazara kushanda.

- Calibratekudzora tembirichazviridzwa nguva dzose kuitira kugadzirisa kwakarurama.

- Shandisa mvura yakanyungudutswa mutangi inotonhorera kudzivirira kuyera uye tarisa mazinga emvura kazhinji.

- Ongorora solenoid mavharuvhu nemakoiri, uchitsiva chero mativi asina mhosva.

- Chengetedza macouplers zuva nezuva uye simbisa kuti kupisa zone relay uye solenoid mavharuvhu anoshanda nemazvo.

- Chenesa vacuum matangi uye makamuri emhepo; tsiva zvindori zvekuvharisa zvakasakara sezvinodiwa.

- Tarisa DC mota mabhurashi uye dzivirira kubva ngura.

- Preheat zvishoma nezvishoma panguva yekutanga uye wedzera screw speed zvishoma nezvishoma.

- Lubricate zvinofamba zvikamu uye simbisa fasteners nguva dzose.

- Kuti uchengetedze kwenguva yakareba, shandisa girisi inodzivirira ngura uye chengetedza masiruu nemazvo.

Zano: Kutevera matanho aya kunobatsira kuchengetedza mhando yechigadzirwa uye hupenyu hurefu hwemidziyo.

Matambudziko Anowanikwa uye Mhinduro

Vashandi vanogona kusangana nematambudziko akawanda panguva yekushanda. Tafura iri pazasi inoratidza matambudziko akajairika uye mhinduro:

| Issue Category | Nyaya Dzakajairika | Zvinokonzera | Zviratidzo | Solutions |

|---|---|---|---|---|

| Mechanical Kukundikana | Screw yanamira | Material buildup, mafuta asina kunaka | Motor overload, ruzha | Chenesa, zora, ongorora |

| Kukundikana Kwemagetsi | Motokari kukundikana | Overheating, short circuit | Hapana kutanga, kupisa | Ongorora sisitimu, dzivirira kuwandisa |

| Process Kukundikana | Plasticization yakaipa | Low speed, tempo isiriyo | Musoro wakakasharara, furo | Rongedza kumhanya, temp, zvinhu |

| Kudzivirira Matanho | Maintenance | Kushaikwa kwekuchenesa, kuongorora | N/A | Rongedza kuchenesa, kuongorora |

Kugara uchiongorora uye kugadzirisa kunodzivirira nyaya zhinji. Vashandi vanofanira kutevera mirairo yemanyorero pakugadzirisa iyo extrusion die kudzivirira kukanganisa.

Mifungo Yekuchengetedza

Laboratory extruder operation inosanganisira njodzi dzinoverengeka. Matanho ekuchengetedza anosanganisira:

- Kupfeka midziyo yekuzvidzivirira yakadai seshangu dzekuchengetedza uye magirazi.

- Kunzvenga mbatya dzisina kusimba pedyo nezvikamu zvinofamba.

- Kugadzika midziyo yese yemagetsi nevashandi vanokwanisa.

- Kuchengeta pasi pakaoma uye kushandisa mapuratifomu kana madhireni kudzivirira kutsvedza.

- Kuisa magadhi pazvikamu zvinofamba kudzivirira maoko.

- Kushandisa mitsetse yekutanga kupinza shinda pachinzvimbo chekudyisa nemaoko.

Ongorora: Kurangwa kwakasimba kwekuchengetedza kunoderedza njodzi yekutsva, kuvhunduka kwemagetsi, uye kukuvara kwemuchina.

Laboratory extruders inotsigira yakachengeteka, inoshanda polymer kugadzirisa kuburikidzakunyatsodzora tembiricha, kudzvanywa, uye screw speed. Vatsvagiri vanobatsirwa kubva mudiki-batch kugadzirwa, kuderedzwa tsvina, uye nekukurumidza prototyping. Modular dhizaini inogonesa kukurumidza kuchinja uye kugadzirisa. Kuenderana kwekuita uye kutarisisa kune zvakadzama kunobatsira kuwana mhedzisiro yakavimbika uye kukurudzira hunyanzvi mukutsvagisa kwepolymer.

FAQ

Ndeapi mapolima anogona murabhoritari imwe screw extruder process?

A rabhoritari imwe sikuruu extruderinogona kugadzirisa akawanda thermoplastics, kusanganisira polyethylene, polypropylene, polystyrene, uye PVC. Vatsvagiri vanowanzo sarudza zvinhu zvinoenderana nezvinodiwa zveprojekiti.

Kubuda kwemhepo kunovandudza sei hunhu hwepolymer?

Kupinza mhepo kunobvisa unyorouye magasi anobva mupolymer anonyunguduka. Iyi nhanho inodzivirira kuremara, senge mabubbles kana nzvimbo dzisina simba, uye inonatsiridza chekupedzisira chigadzirwa chemichina.

Vafambisi vanodzora sei tembiricha yeextrusion?

Vashandi vanoseta uye vanotarisa kupisa kwembiya vachishandisa control system. Sensors inopa chaiyo-nguva mhinduro, ichibvumira kunyatsogadziridzwa kweinofanana kunyungudika kwepolymer uye kuumbwa.

Nguva yekutumira: Jul-01-2025