Bhodhoro Blow molding screw barrel dhizaini inomira parutivi kubva mukuumbwa kwejekiseni nekuda kwehurefu hwayo uye yakakwirira compression ratio. Izvi zvinobatsira kugadzira yunifomu parisons, iyo inovandudza kujeka kwebhodhoro uye kusimba. Sezvo musika wepasi rose wakaumbwa wepurasitiki uchikura, iwoKufuridza Screw BarreluyeFirimu Inoputika Chikukuruunza kunyungudika kwakanaka, kusanganisa, uye kuchengetedza simba pamusoro peSingle Plastic Screw Barrel.

Screw Barrel Basa muMolding Maitiro

Kunyunguduka Kwezvinhu uye Basa Rokupa

Iyo screw barrel inoita semoyo wezvose zviri zviviri bhodhoro kuumba nekuumba jekiseni muchina. Basa rayo guru nderekunyungudutsa mapepa epurasitiki uye kufambisa zvinhu zvakanyungudutswa mberi. Mukuumba jekiseni, screw inotenderera mukati membiya inopisa, ichimanikidza uye ichinyungudutsa plastiki. Kana purasitiki yanyunguduka, screw inoisundira muforoma pakumanikidzwa kukuru. Iyi nzira inoumba plastiki kuita zvikamu zvakasimba.

Mukuumba bhodhoro, screw barrel inonyungudutsa iyo polymer. Zvisinei, mafambisirwo azvinoitwa zvinhu anogona kuchinja. Semuenzaniso, mu extrusion blow molding, screw inogona kutendeuka ichienderera kana mumatanho. Inosaidzira purasitiki yakanyungudutswa kunze sechubhu, inonzi parison. Mhepo inobva yavhuvhuta ichipinda muprison kuita bhodhoro. Mukuumba jekiseni, screw inopinza purasitiki yakanyungudutswa muforoma kugadzira preform, inozova bhodhoro. Iyo screw barrel inogadzirisa basa rayo zvichienderana nemaitiro ekuumba, asi inogara yakatarisana nekunyunguduka uye kufambisa purasitiki zvakanaka.

Zano:Iyo yakagadzirwa zvakanaka screw barrel inovimbisa kuti plastiki inonyunguduka zvakaenzana uye inoyerera zvakanaka, iyo inobatsira kudzivirira kukanganisa mune yekupedzisira chigadzirwa.

Kusanganiswa uye Homogeneity Migumisiro

Kusanganisa uye homogeneity kunoita basa rakakura mumhando yechigadzirwa. Iyo screw barrel inofanirwa kusanganisa purasitiki uye chero zvekuwedzera kuitira kuti chikamu chekupedzisira chitarise uye chiite sezvanga zvichitarisirwa. Yakasiyana screw dhizaini inogona kushandura masanganiswa epurasitiki. Semuyenzaniso, screws ane akakosha chiteshi kana kusanganisa zvikamu zvinobatsira kugovera colorants uye zvinowedzera zvakaenzana. Izvi zvinotungamirira kune mavara ari nani uye mashoma asina simba mavara.

Vagadziri vanowanzo edza kuti screw inosanganiswa sei nekutarisa tembiricha uye ruvara rwepurasitiki yakanyungudutswa. Vanotarisa kunyange tembiricha uye musanganiswa wemavara akatsetseka. A lowermureza kutsaukamuzviedzo izvi zvinoreva kusanganisa kuri nani. Mamwe masiruuru epamberi, senge zvipingamupinyi kana madhizaini akawanda, anoratidza kusanganiswa kwakagadziridzwa uye mamwe mayunifomu anonyungudika. Aya maficha anobatsira kugadzira mabhodhoro uye zvikamu zvakasimba, zvakajeka, uye zvisina mitsetse kana mabhubhu.

| Measurement Aspect | Tsanangudzo Yenzira | Zvarinoratidza |

|---|---|---|

| Thermal Homogeneity | Tarisa tembiricha yekunyungudika pane screw tip | Kunyange kudziyisa |

| Material Homogeneity | Ongorora musanganiswa weruvara mumasampuli akanyunguduka | Kunyangwe kusanganisa |

| Screw Performance Index | Inobatanidza zvose zvinopisa uye zvinhu homogeneity | Zvose zvinonyungudika |

Iyo screw barrel inosanganiswa zvakanaka inopa vagadziri kutonga kwakawanda pamusoro pemhando yechigadzirwa uye inoderedza tsvina.

Misiyano Yakakosha muScrew Barrel Dhizaini

Geometry uye Dimensions

Screw barrel geometry maumbirwo mafambisirwo epurasitiki uye kunyungudika mukati memuchina. Mukuumba bhodhoro, screw barrel inowanzova nehurefu-kusvika-diameter (L / D) reshiyo kana ichienzaniswa nekuumbwa kwejekiseni. Uhu hurefu hwakawedzerwa hunopa plastiki nguva yakawanda yekunyunguduka uye kusanganisa, izvo zvakakosha pakugadzira mabhodhoro akasimba, akajeka. Iyo Bhodhoro Blow molding screw barrel inowanzo ratidza zvishoma nezvishoma taper uye yakadzika mafidhi nzira. Idzi sarudzo dzekugadzira dzinobatsira screw kubata kuyerera kwakadzikama kwepurasitiki uye kugadzira yunifomu parison.

Injection molding screw barrels, kune rumwe rutivi, inowanzove ipfupi. Vanotarisa nekukurumidza kunyunguduka uye kupinza plastiki muforoma. Hurefu hupfupi hunobatsira kukurumidza kutenderera nguva uye inokodzera kukurumidza-paced chimiro chekuumba jekiseni. Iyo geometry yega yega screw barrel inoenderana nezvinodiwa zvemaitiro ayo, kuenzanisa kunyungudika, kusanganisa, uye kudzvanywa.

Ongorora: Iyo chaiyo geometry inogona kunatsiridza kunyunguduka uye kuderedza kushandiswa kwesimba nekudzora kuwanda kwekugera uye kupisa zviitiko zvepurasitiki.

Compression Ratio uye Functional Zones

Iyo compression ratio chikamu chakakosha che screw barrel dhizaini. Iyo inoyera kuti yakawanda sei screw inodzvanya purasitiki painofamba kubva kunzvimbo yekudyisa ichienda kunzvimbo yemamita. Mukuumba bhodhoro, Bhodhoro Blow kuumba screw barrel inowanzoshandisa yakakwira compression ratio. Izvi zvinobatsira kuvaka dzvinyiriro inodiwa kuti iite parini yakatsetseka, isina bubble. Iyo yepamusoro reshiyo zvakare inovandudza kusanganisa uye kunyungudika homogeneity, izvo zvinotungamira kune nani kujeka kwebhodhoro uye kusimba.

Injection molding screw barrels inogona kushandisa yakaderera kana ine mwero compression reshiyo, zvichienderana nezvinhu. Semuenzaniso, yakaderera compression reshiyo inogona kukonzera kuremara senge splay mu polystyrene, nepo reshiyo yepamusoro inovandudza compaction uye inoderedza kutenderera nguva. Nekudaro, kana reshiyo yakawandisa kune zvimwe zvinhu zvakaita seABS, inogona kukonzera kusagadzikana kwemaitiro uye kunyungudika kusina kukwana. Dhizaini yenzvimbo dzinoshanda-yekudya, shanduko, uye metering-inotambawo basa guru. Kugadzirisa kudzika uye kureba kwenzvimbo idzi kunoshandura kuti mapurasitiki anonyungudika nekuyerera sei, zvichikanganisa kudzvanywa uye kuita screw.

- Compression ratio inofanirwa kuenderana nerudzi rwepolymer uye maitiro ezvinodiwa.

- Dhizaini yakakodzera yenzvimbo dzinoshanda inovimbisa kunyungudika kwakadzikama uye inodzivirira kukanganisa.

- Kunyatsogadzirisa zvinhu izvi zvinogona kuvandudza kunaka kwekunyunguduka uye kuwedzera simba rechirimwa.

Material Kubata uye Plasticizing Zvinodiwa

Akasiyana ekuumba maitiro ane akasiyana eplasticizing zvinodiwa. Iyo Bottle Blow molding screw barrel inofanirwa kubata zvakasiyana-siyana zvezvinhu, kubva pakakwirira-density polyethylene (HDPE) kusvika ku polypropylene (PP). Inoda kunyunguduka nekusanganisa zvinhu izvi zvakaenzana kugadzira parini ine ukobvu hunoenderana. Izvi zvakakosha nekuti kunyungudika kusina kuenzana kunogona kutungamirira kunzvimbo dzisina simba kana mabhodhoro ane makore.

Injection molding screw barrels inotarisa kukurumidza kunyungudutsa purasitiki uye kuipinza muforoma. Ivo vanowanzo shanda nezvinhu zvinoda kunyatso kudzora tembiricha uye nekukurumidza plasticizing. Zvimwe zvinhu, sengehigh-viscosity resins, inogona kuve yakaoma kugadzirisa mukuumba jekiseni kuvhuvhuta. Iyo screw barrel dhizaini inofanirwa kuverengera misiyano iyi kuti ive nechokwadi chekushanda kwakanaka.

| Aspect | Extrusion Blow Molding (EBM) | Jekiseni Blow Molding (IBM) |

|---|---|---|

| Zvimedu | 5% kusvika 30% zvimedu, inoda kudzokororwa, inowedzera musiyano. | Zvimedu zviduku zvine midziyo yakakodzera; chete kubva pakutanga-up kana kuchinja kwemavara. |

| Plastic Orientation | Parison inofuridzwa pamhepo yakakwira, yakatarisa zvishoma. | Kumwe kutaridzika panguva yejekiseni, inovandudza zvivakwa. |

| Mutengo Wekushandisa | Yakaderera, yakanakira kumhanya kudiki. | Yakakwirira, asi inoshanda kune yakakura kumhanya. |

| Kujeka | Zvinogoneka kufa mitsetse kana kuremara. | Bvisa midziyo nekuda kwekutonga kuri nani. |

| Pazasi Pinch-off Scar | Ikozvino, inogona kukanganisa chitarisiko. | Hapana, chitarisiko chakanaka uye simba. |

| Pazasi Push-off | Zvakaoma nekuda kwepinch-off. | Zviri nyore nemapulagi anogona kudzokororwa. |

Zano: Kufananidzascrew barrel designkuzvinhu uye maitiro anobatsira kuderedza zvimedu, kunatsiridza kujeka, uye kugadzira mabhodhoro akasimba.

Pfeka Resistance uye Material Kuenderana

Kupfeka kuramba ndiko kunetseka kukuru kune ese ari maviri kuvhuvhuta bhodhoro nekuumba jekiseni. Iyo screw uye mbiya inotarisana inogara ichikweshana uye kumanikidza kubva mupurasitiki inofamba. Mafirita uye ekuwedzera mupurasitiki anogona kuita kuti kupfeka kuve kwakanyanya. The Bottle Blow moldingscrew barrelkazhinji inoshandisa yemhando yepamusoro nitrided simbi, bimetallic alloys, kana akakosha machira senge tungsten carbide kurwisa kupfeka uye ngura. Zvinhu izvi zvinobatsira screw kugara kwenguva refu, kunyangwe kana ichigadzira abrasive kana corrosive polymers.

Majekiseni ekuumba madhiramu anogona kushandisa zvinhu zvakaita seNitralloy nitride, D2 chishandiso simbi, CPM 10V, kana kunyange carbide kumabasa akaomarara. Chinhu chega chega chinopa mazinga akasiyana ekudzivirira kubva pakupfeka uye ngura. Semuyenzaniso, CPM 10V inoshanda zvakanaka nemapurasitiki akazadzwa negirazi kana anodzoreredza moto, ukuwo madhiramu ecarbide ari akanakisa pazvinhu zvinokurisa. Kufananidza screw uye dhiramu zvinhu zvakakosha kudzivirira matambudziko nekuwedzera kwekupisa uye kusunga.

- Nyaya dzekupfeka dzakajairika dzinosanganisira kuroora, kupfeka abrasive, uye kusarongeka kupfeka.

- Kushandisa zvinhu zvakakodzera uye machira kunowedzera hupenyu hwe screw barrel.

- Kugara uchiongorora maitiro ekupfeka kunogona kubatsira kuona matambudziko ekutanga uye kutungamira dhizaini yekuvandudza.

Rangarira: Iyo yakanyatsosarudzwa screw barrel material inochengeta muchina uchishanda zvakanaka uye inoderedza nguva yekudzikira pakugadzirisa.

Bhodhoro Blow Molding Screw Barrel Features

Dhizaini Magadzirirwo eParison Hunhu

Vagadziri vanogadzira Bhodhoro Blow molding screw barrel ine akati wandei maficha ekuvandudza eparison mhando. Izvi zvinogadziriswa zvinobatsira kugadzira mabhodhoro ane kunyange madziro uye nzvimbo dzakatsetseka. Heano mamwe ezvakanyanya kukosha dhizaini sarudzo:

- Iyo screw barrel inopa chaiyo kutonga pamusoro pekuti plastiki inonyungudika nekuyerera sei. Kudzora uku kunobatsira kuchengeta yunifomu yemadziro eparison, inotungamira kumabhodhoro anotaridzika zvakanaka.

- Mainjiniya anoshandisa zvinhu zvepamusoro-giredhi senge nitrided simbi, bimetallic alloys, uye tungsten carbide coatings. Zvishandiso izvi zvinoita kuti screw barrel igare yakasimba uye isingarambe kupfeka, saka inoramba ichishanda zvakanaka nekufamba kwenguva.

- Customization yakajairika. Vagadziri vanogona kushandura dhayamita yescuru, kureba-kusvika-dhayamita reshiyo (L/D), chimiro chekubhururuka, uye machira epamusoro. Idzi sarudzo ngadziite kuti dzifananidze screw barrel kune akasiyana mapurasitiki uye zvinodiwa zvekugadzira.

- Aya madhizaini maficha anobatsira kukwidziridza zvakakosha kugadzirisa zvinhu. Semuenzaniso, vanogona kupfupisa nguva dzekutenderera, kunatsiridza kutonhora, uye kuita saizi yemabhodhoro kuwanda.

Yakagadzirwa zvakanakaBhodhoro Blow molding screw barrelinopa makambani kutonga zvakanyanya pamusoro pechigadzirwa chekupedzisira, zvichiita kuti zvive nyore kugadzira mabhodhoro anotaridzika zvakanaka uye anoita zvakanaka.

Kudzora Tembiricha uye Homogeneity

Kudzora tembiricha kunoita basa rakakura mukuvhuvhuta. Iyo screw barrel inofanirwa kuchengetedza purasitiki iri patembiricha chaiyo kuti ive nechokwadi chekuti inonyungudika zvakaenzana uye inoyerera zvakanaka. Kana tembiricha yakakwira zvakanyanya kana yakadzikira, purasitiki inogona kusagadzira parini yakanaka.

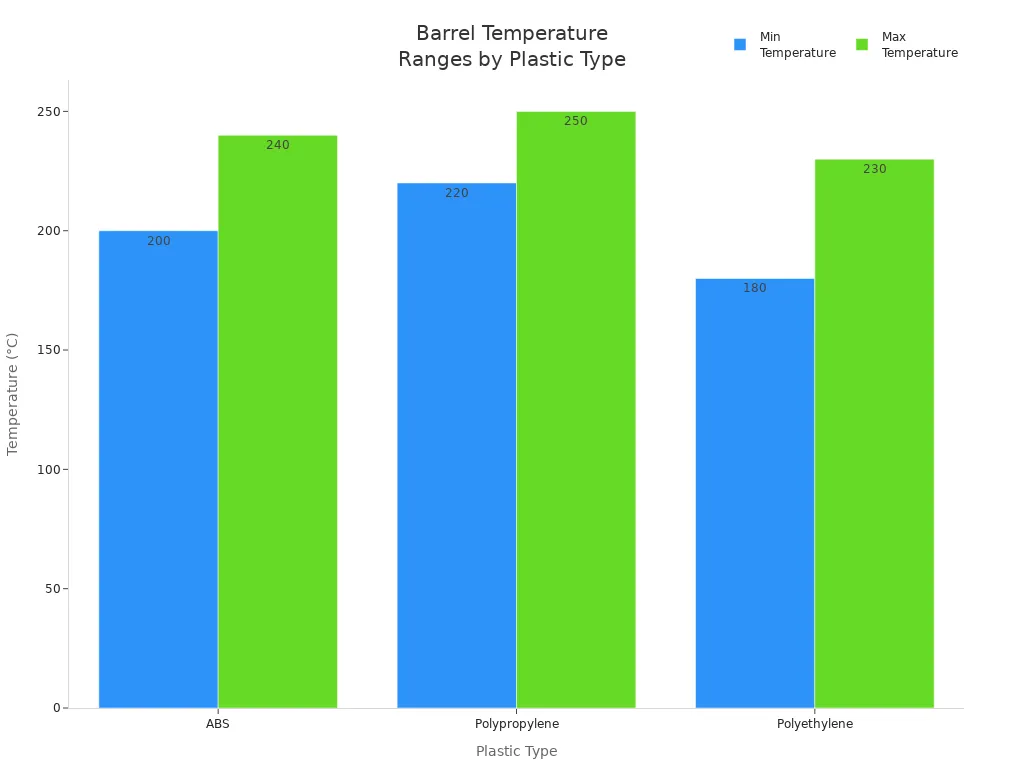

| Plastic Type | Yemazuvano Tembiricha yeBarel (°C) |

|---|---|

| ABS | 200 - 240 |

| Polypropylene | 220 - 250 |

| Polyethylene | 180 - 230 |

Vashandisi vanoshandisa mabhendi ekudziya uye masensa kubata tembiricha idzi. Iyo screw dhizaini inokanganisawo kuti mapurasitiki anopisa sei uye anosanganiswa. Nzvimbo dzinopisa dzinogona kuoneka munzvimbo yekushandura screw, zvichiita kuti tembiricha iwedzere. Kugadzirisa izvi, vagadziri vanogona kugadzirisa screw speed, kuwedzera kutonhora mafeni, kana insulate heater mabhendi. Aya matanho anobatsira kuchengetedza tembiricha yakanyunguduka yakatsiga, inova kiyi yekugadzira mabhodhoro ane hunoenderana mhando.

A yakanaka Bhodhoro Blow moldingscrew barrel designzvakare inovandudza homogeneity. Zvimiro zvakaita se grooved feed screws uye ndege dzakadzika dzinobatsira purasitiki kunyunguduka nekusanganisa zvirinani. Zvipingamupinyi zvinosanganisa zvikamu padhuze nekupera kwescrew sanganisa iyo polymer zvakaenzana. Iyi yunifomu inonyungudika inotungamira kugadzika kweparison kuumbwa uye kushomeka kwehurema.

Apo kutonhora kunoramba kwakadzikama uye kunyunguduka kwakafanana, nzira yacho inomhanya uye mabhodhoro anobuda akasimba uye akajeka.

Kukanganisa paBhodhoro Kujeka uye Simba

Iyo dhizaini yescrew barrel ine mhedzisiro yakananga yekuti akajeka uye akasimba sei mabhodhoro akapedzwa. Siruuru refu ine yakakwirirakureba-kune-dhayamita reshiyo (kazhinji iri pakati pe24:1 ne30:1)inopa plastiki nguva yakawanda yekunyunguduka nekusanganisa. Yepamusoro yekumanikidza reshiyo, kazhinji yakatenderedza 3.5: 1, inobatsira kugadzira yakatsetseka, isina bubble-isina kunyungudika. Aya maficha anoshanda pamwechete kuvandudza kuyerera kwepurasitiki uye kunaka kweparison.

Kufambira mberi mune screw barrel tekinoroji yakaita kuti zvive nyore kugadzira mabhodhoro akareruka pasina kurasikirwa nesimba. Kufambiswa kwezvinhu kwakagadziridzwa kunoderedza kuvharika uye kunoita kuti kugadzirwa kurambe kuchimhanya. Yakagadziridzwa kupisa kupisa kunobatsira kuchengetedza yakanakisa kugadzirisa tembiricha, izvo zvinotungamira kune nani kunyungudika mhando uye mamwe anowirirana mabhodhoro. Durable materials senge heat-treated alloy steel zvinoreva kugadzirisa kushoma uye kushomeka nguva.

Vagadziri vanogonawo kugadzirisa screw barrel kuti ikwane zvakasiyana siyana zvekugadzira zvinodiwa. Vamwe vanoshandisa masensa akabatanidzwa kuti atarise kunyunguduka uye tembiricha munguva chaiyo. Izvi zvinobvumira kugadzirisa nekukurumidza uye zvinobatsira kudzivirira matambudziko asati akanganisa chigadzirwa.

- Grooved feed screws uye ndege dzakadzika dzinovandudza resin kunyunguduka uye kusanganisa, iyo inokosha pakugadzira mabhodhoro akajeka.

- Zvipingamupinyi zvinosanganisa zvikamu zvinovimbisa iyo polymer inosanganiswa zvakaenzana, kuderedza mitsetse uye isina simba nzvimbo.

- High compression ratios inobvumira kutetepa, kureruka kwemabhodhoro madziro uchiachengeta akasimba.

Nekuvandudzwa kwemagadzirirwo aya, makambani anogona kugadzira mabhodhoro asiri kureruka chete asiwo akajeka uye akaomarara, achizadzisa zvinodiwa neindasitiri yemazuva ano yekurongedza.

Kuenzanisa Tafura: Bhodhoro Blow Molding vs. Injection Molding Screw Barrels

Side-ne-Side Feature Summary

Pakufananidza kuumbwa kwebhodhoro uyeinjection molding screw barrels, misiyano yakawanda inooneka. Tafura iri pazasi inoratidza zvakanyanya kukosha maficha parutivi:

| Feature | Bhodhoro Blow Molding Screw Barrel | Injection Molding Screw Barrel |

|---|---|---|

| Plastic Melting Method | Inonyunguduka uye inoburitsa epurasitiki kuita parini isina mhango | Inonyunguduka uye inopinza epurasitiki mune preform mold |

| Product Dimensionality | Inogadzira 2D makomba zvigadzirwa semabhodhoro nemidziyo | Inogadzira 3D hollow zvikamu zvine hupamhi hwepamusoro |

| Zvinhu Zvakashandiswa | HDPE, PP, PET | Acrylic, Polycarbonate, POM, PE |

| Mold Dhizaini & Kururamisa | Flexible dhizaini, yakaderera chaiyo | Yakanyanya kurongeka, kuyerera kwakaringana resin |

| Scrap Generation | Inogadzira flash inoda kuchekwa | Yemahara-isina, hapana kucheka kunodiwa |

| Tooling Costs | Yakaderera, flexible tooling | Yakakwirira, isingachinjiki |

| Production Speed | Zvishoma, hunyanzvi hwemushandisi hwakakosha | Inokurumidza, yakanakira vhoriyamu yakakwirira |

| Product Types | Zvirongo zvakakura, zvimiro zvakaoma, zvibato | Zvidiki, zvikamu chaizvo zvine kushivirira kwakasimba |

| Weight & Material Control | Zvisina kunyatsojeka, zvakaoma kuyera ukobvu hwemadziro | Chaiyo uremu uye yunifomu zvinhu kugovera |

| Container Size Range | isingasviki 1 oz. kusvika ku55 galoni | Yakanakira 5 oz. kana zvishoma, kwete zvehupfumi kupfuura 16 oz. |

| Mold Zvinodiwa | Single mold type | Inoda jekiseni nekuputira molds |

Zano:Kugaro gadzirisa kunoita kuti marudzi ese ari maviri escrew barrels afambe zvakanaka. Pakuumba bhodhoro, vashandisi vanochenesa screw uye mbiya kazhinji kudzivirira zvakasara kuvaka. Vanoongororawo tembiricha uye vanoisa zvidimbu zvinofamba. Mukuumba jekiseni, zvikwata zvinoongorora screw nedhiramu gore rega rega, tarisa maitiro akasiyana, uye chengetedza hydraulic mafuta nemabhandi ekudziya. Aya matanho anobatsira kuve nechokwadi chemhando yechigadzirwa uye kuwedzera hupenyu hwemidziyo.

Vagadziri vanoona mutsauko wakajeka mune screw barrel dhizaini yekuumba bhodhoro uye jekiseni kuumba. Iyo Bhodhoro Blow molding screw barrel inoshandisa yakareba geometry uye chaiyo tembiricha yekudzora kuti iwedzere kunaka kweparison. Zvinhu zvakakosha senge screw chimiro, kusarudzwa kwezvinhu, uye chaiyo-nguva yekutarisa inobatsira kuvandudza kushanda uye kuenderana kwechigadzirwa.

- Screw geometry maumbirwo anonyunguduka uye kusanganisa, kuderedza tsvina nekuvandudza mhando.

- Kunyatsosarudzwa kwezvinhu kunodzivirira kupfeka uye kupisa, kunyanya nemapurasitiki abrasive.

| Dambudziko | Impact on Manufacturing |

|---|---|

| Kusarudzwa kwezvinhu | Inodzivirira kupfeka uye kuwedzera hupenyu |

| Kudzora tembiricha | Inochengetedza kujeka kwechigadzirwa uye simba |

| Maitiro ekushanda | Inoderedza downtime uye kukanganisa |

Kusarudza iyo chaiyo screw barrel dhizaini inotungamira kune ari nani mabhodhoro, shoma tsvina, uye yakatsetseka kugadzirwa.

FAQ

Chii chinoita kuti blow molding screw barrel isiyane nejekiseni rekuumba screw barrel?

A blow moldingscrew barrelrakareba uye rinoshandisa reshiyo yepamusoro yekumanikidza. Iyi dhizaini inobatsira kugadzira yunifomu maparini emabhodhoro akasimba, akajeka.

Ko screw barrel dhizaini inokanganisa sei kunaka kwebhodhoro?

Iyo screw barrel inodzora kunyunguduka uye kusanganisa. Dhizaini yakanaka inotungamira kune kunyangwe kukora kwemadziro, kujeka kuri nani, uye mabhodhoro akasimba.

Vagadziri vanogona kushandisa imwechete screw barrel kune ese maviri maitiro?

Kwete, maitiro ega ega anoda chaiyo screw barrel. Kushandisa dhizaini yakakodzera kunovimbisa kushanda zvakanaka uye zvigadzirwa zvemhando yepamusoro.

Nguva yekutumira: Jul-25-2025